6

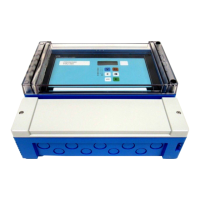

Prosonic T - FMU 130, 131, 230, 231, 232

Endress+Hauser

Function

An ultrasonic emitter (sensor) mounted above the product is electronically activated and

directs an ultrasonic pulse through the air towards the product. This pulse is reflected

back from the surface of the product. The echoes partially reflected are detected by the

same sensor, now acting as a receiver, and converted back into an electrical signal. The

time taken between transmission and reception of the pulse –

time-of-flight

– is directly

proportional to the distance between the sensor and the product surface.

Application and Measuring Ranges

The Prosonic T is a compact ultrasonic transmitter for continuous non-contact level

measurement in liquids and in coarse-grained or pelleted solids (grain size from 0.16

inches/4 mm). It has an integrated temperature sensor for time-of-flight compensation.

The Prosonic T series consists of three transmitters, which can be equipped with one of

several electronics modules, with graduated measuring ranges from 0.82 feet (0.25 m)

upwards.

FMU 130 FMU 131 FMU 230 FMU 231 FMU 232

1½² 2² 1½² 2²4²

ft (m) ft/m ft/m ft/m ft/m

0.8-13.1 (0.25-4) 1.3-23 (0.4-7) 0.8-13.1 (0.25-4) 1.3-23 (0.4-7) 2-49.2 (0.6-15)

0.8-6.5 (0.25-2) 1.3-11.5(0.4-3.5) 0.8-6.5 (0.25-2) 1.3-11.5 (0.4-3.5) 2-23 (0.6-7)

Without

FF A A—

Communication

HART B B C C —

INTENSOR A A B B —

PROFIBUS PA P P P P P

2-Wire, 4 to 20 mA Loop-Powered

Sensor / Process

connection

Measuring ranges

liquid:

solid:

FMU 230 FMU 231 FMU 232

1½² 2² 4²

ft/m ft/m ft/m

0.8 -16.4 (0.25-5) 1.3-26 (0.4-8) 2-49 (0.6-15)

0.8-6.5 (0.25-2) 1.3-11.5 (0.4-3.5) 2-23 (0.6-7)

Power Supply 180 90 18 180 90 18 180 90 18

to to to to to to to to to

250 127 36 250 127 36 250 127 36

V AC V AC V DC V AC V AC V DC V AC V AC V DC

Without

FJ D F JD FJD

Communication

HART G K E G K E G K E

PROFIBUS-PA

(2-wire) P P P P P P P P P

4-Wire, Including Power Supply

Sensor / Process

connection

Measuring ranges

liquid:

solid:

Electronics versions

FMU X3X

Electronics versions

FMU X3X

Loading...

Loading...