Envent Engineering Ltd. Page 39 Revision 2.4

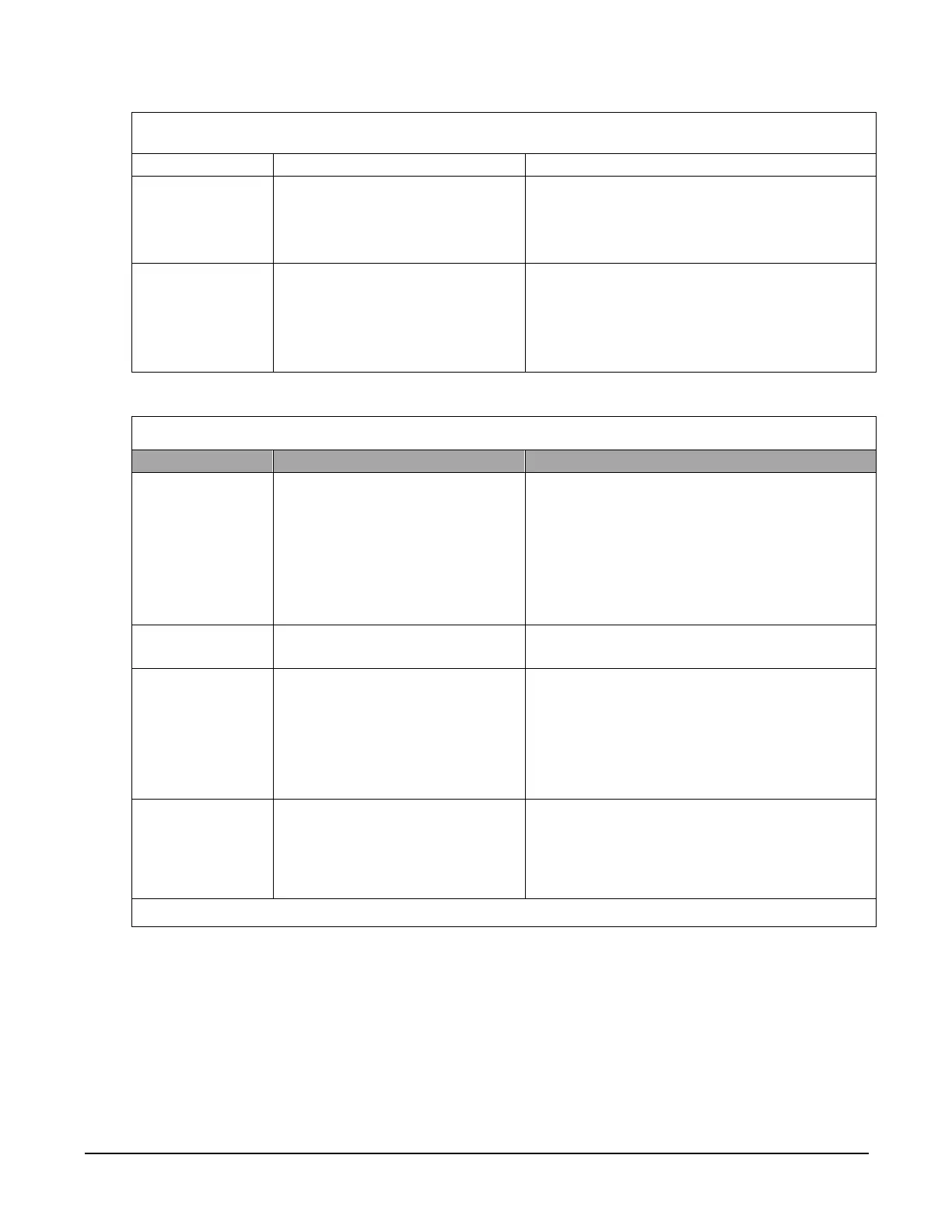

H2S Sensing Tape Issues (Cont’d)

Sensor/ sensor wire failure Try re-zeroing the sensor. Refer to "Re-zero

Sensor procedure" on page 29.

If procedure fails, Sensor or sensor wire

may require replacement.

H2S sensing

Tape coming

out of sample

chamber/trigger

slide

Trigger slide not seated

properly

Ensure trigger slide is seated in groove of

sample chamber

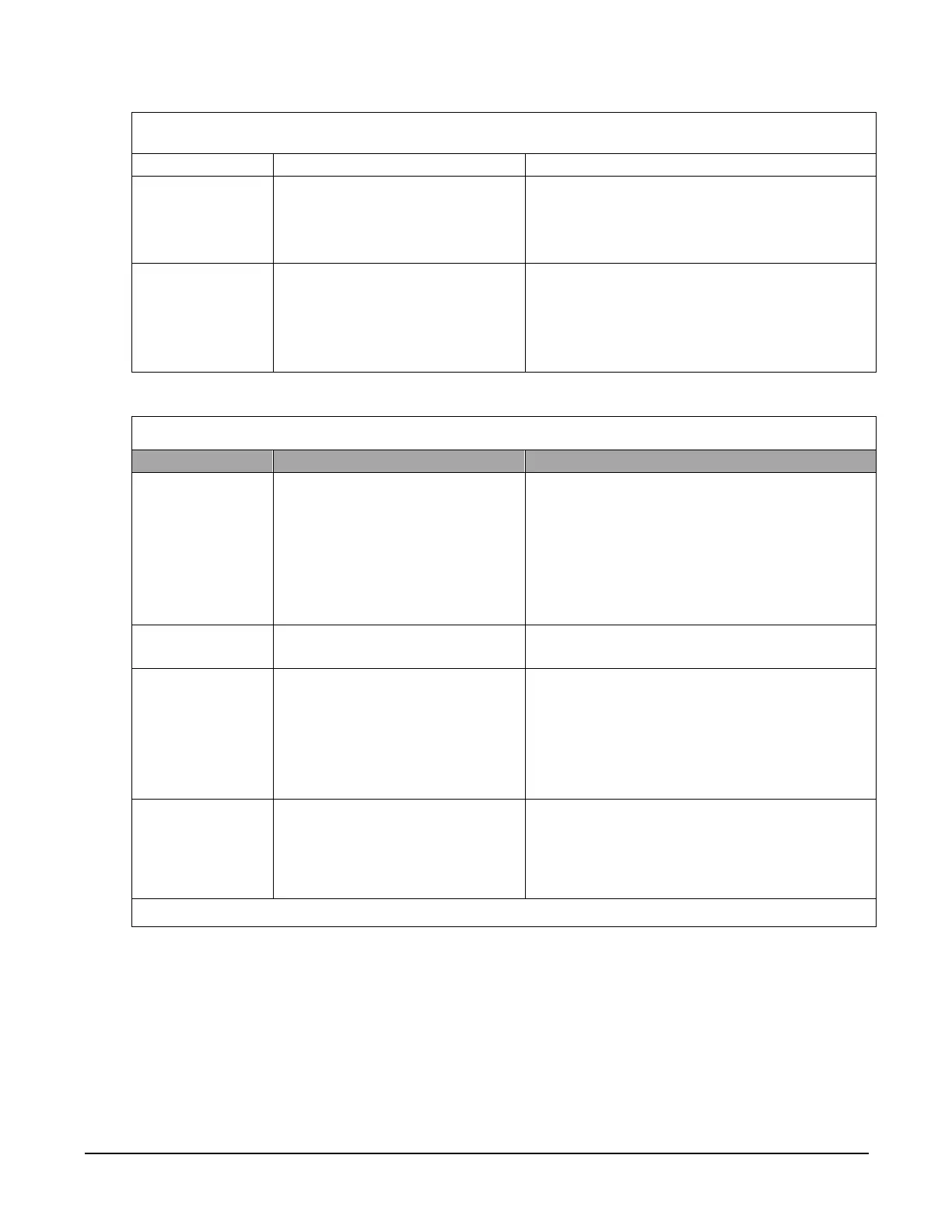

Electronics Issues

Fault LED

(Sensor High)

Incorrect zeroing Make sure the H2S Sensing tape is

installed properly and do a motor run.

To do a motor run: Display>Press Menu

Button until "MTR Run">Press right button.

This will activate the motor and move the

H2S Sensing tape for a few seconds. The

alarm should clear.

Faulty Sensor Sensor needs to be replaced. Contact

Envent Engineering Ltd for replacement.

Fault LED

(Sensor Low)

Sensor did not zero on white

H2S sensing tape because

H2S sensing tape came out of

sample chamber slot

Re-install H2S Sensing tape. Refer to "H

2

S

Sensing Tape Change Procedure" on page

31 or on sticker in the analyzers door.

Re-zero sensor block. Refer to Refer to

"Re-zero Sensor procedure" on page 29.

Sensor/ sensor wire failure Re-zero the sensor block. Refer to "Re-zero

Sensor procedure" on page 29. If procedure

fails, sensor or sensor wire may require

replacement.

Continued on next page

Loading...

Loading...