Envent Engineering Ltd. Page 40 Revision 2.4

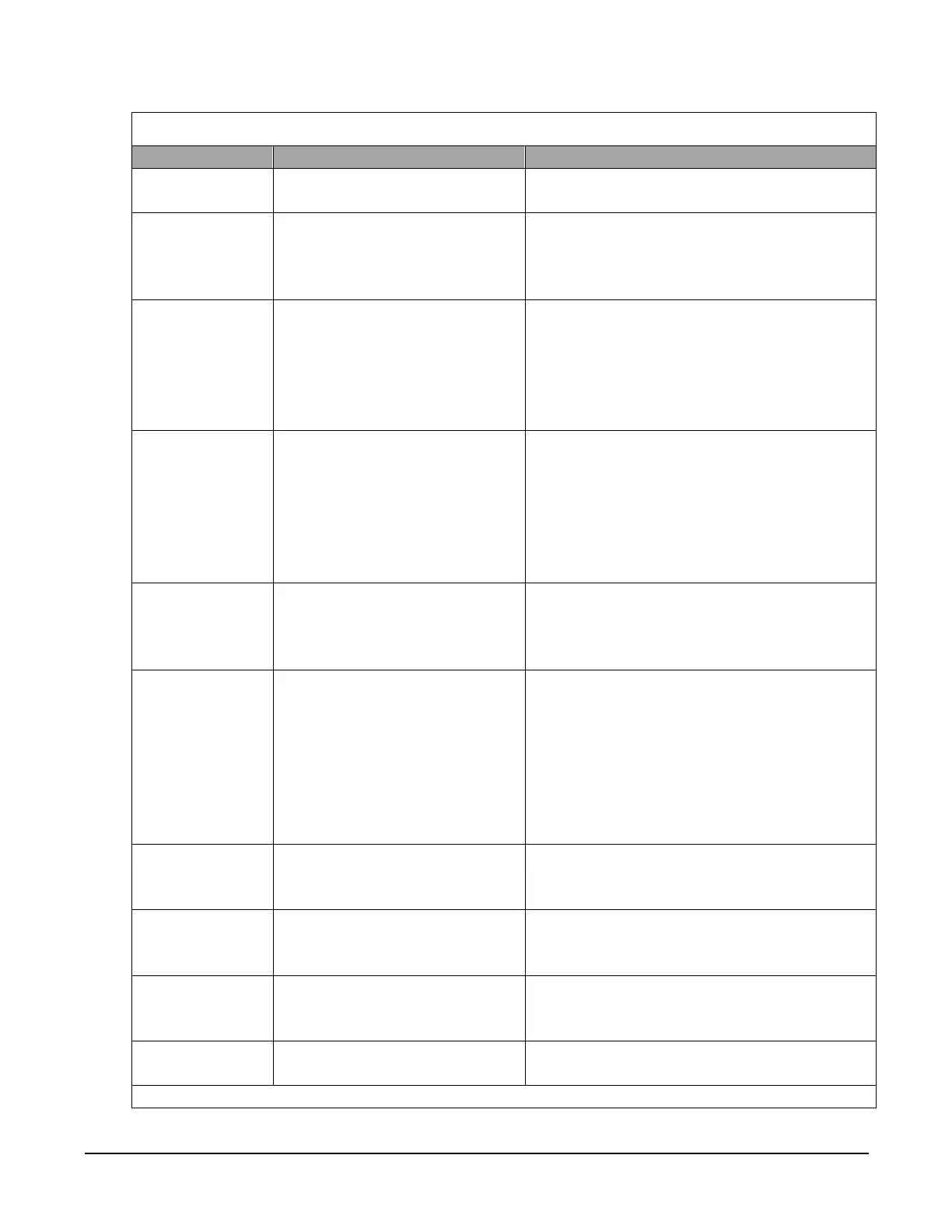

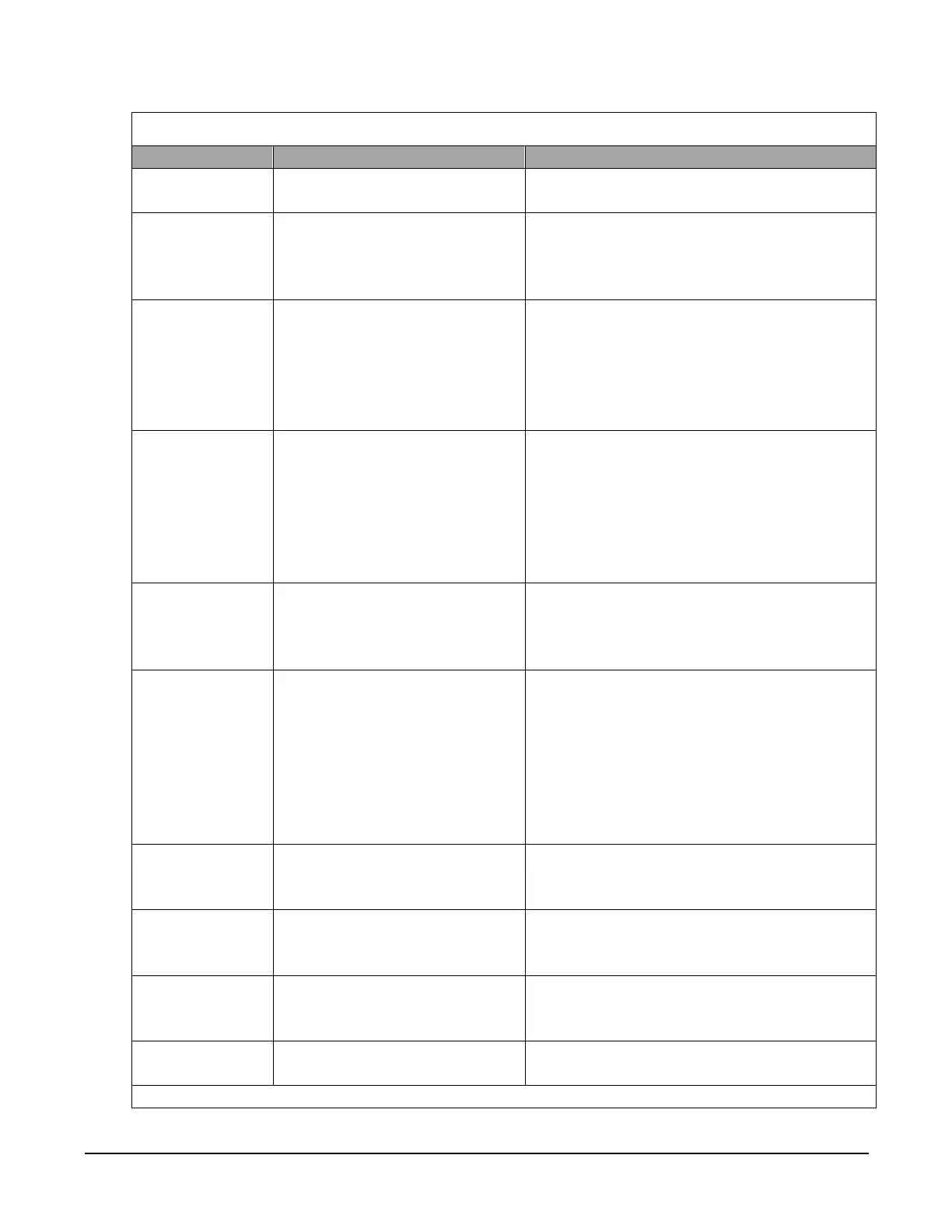

Electronics Issues (Cont’d)

IS Barrier failure (For 330S

analyzer series only)

IS Barrier may need replacement. Consult

Envent Engineering Ltd.

Contaminants in sample

chamber

Clean sample chamber. Replace aperture

and window if required. Contact Envent

Engineering Ltd for replacement and

assistance.

Fault LED (Low

H2S sensing

Tape)

New H2S sensing tape is

required

H2S Sensing tape requires change

(Average of 2 to 3 days left, from the

moment alarm goes off, for the tape to be

completely used up). Refer to "H

2

S Sensing

Tape Change Procedure" on page 31 or on

sticker in the analyzers door.

Low H2S sensing tape sensor

failure

If the alarm does not clear once a new H2S

sensing tape is installed, the low H2S

sensing tape sensor or its wires have failed

and need to be replaced. Consult Envent

Engineering Ltd to order a replacement.

Low H2S sensing Tape Sensor Part #:

330046A

Fault LED (Low

Pressure)

Pressure of sample gas is

lower than setpoint of pressure

switch (factory set to 10 psi

descending)

Inspect the sample inlet upstream to

troubleshoot the problem.

Pressure switch failed If pressure is above 10 psi and alarm

continuous, the pressure switch setpoint

might have changed. Set back to 10 psi

descending. Also, check pressure switch

wiring

If the problem persists, pressure switch

might need replacement. Contact Envent

Engineering Ltd.

Pressure regulator failed The problem might be coming from the

pressure regulator. Troubleshoot and

consult Envent Engineering Ltd.

Fault LED

(Oven Fail)

Fuse not installed. Fuse for furnace does not come installed in

the controller board. Please check spare

fuse bag and install fuse.

Oven not working properly Oven failed and temperature has dropped

below the optimal temperature. Please

consult Envent Engineering Ltd.

Blank Display Contrast needs adjustment Change contrast by turning the

potentiometer in the display board.

Continued on next page

Loading...

Loading...