JOHNSON CONTROLS

10

FORM ET130.13-NOM3 (708)

Series Flow ECM Motor Balancing

Fan must be energized prior to intro-

duction of air through the primary

air valve or the possibility exists that

the fan wheel will operate backward

(counter rotation). Reverse / counter

rotation of the blower over a period of

time will damage the ECM motor.

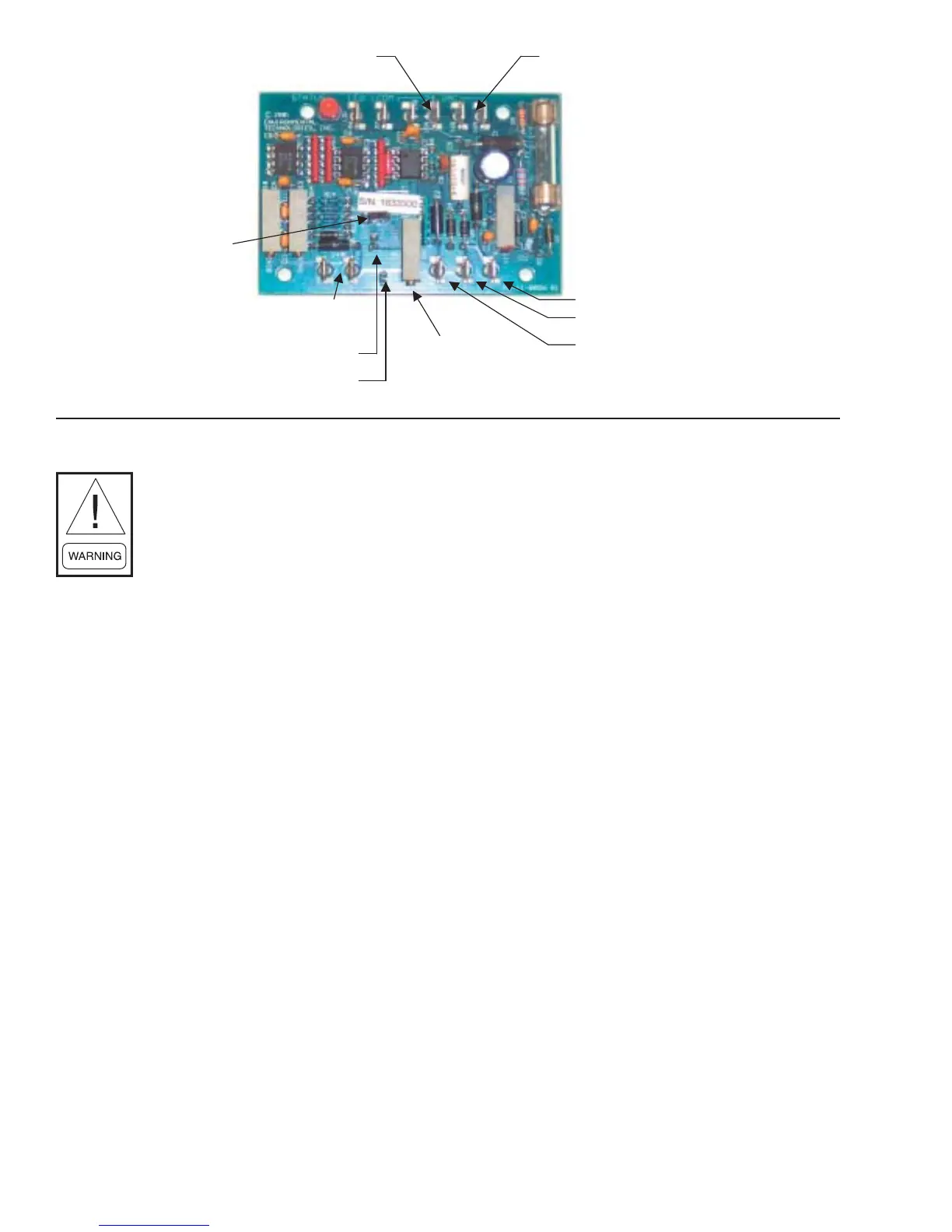

See Figure 2 for ETPWM Board Layout.

Commissioning

1. If remote balancing dampers are present set them

to full open.

2. Make sure there are no obstructions in the discharge

ductwork and/or at the plenum opening. If the unit

has a radiated sound damper at the plenum opening,

make sure it swings freely.

3. With unit de-energized, disable fan by disconnect-

ing one of the wires leading to fan relay coil or

contacts.

4. Energize unit.

5. Verify that there is 22 to 28 VAC across terminals

15 and 16 of ETPWM board.

6. Verify that there is 15 VDC across terminals G (+)

and COM (-) of ETPWM board.

7. Connect voltmeter to wire loop VDC (+) and wire

loop COM (-) of ETPWM board. Verify DC volt-

age is between 5.1 and 9.9 VDC.

8. De-energize unit and reconnect wire to fan relay

removed in step 3. Make sure that all wires are

reconnected per electrical schematic shipped with

unit.

9. Energize unit and let motor operate for a minimum

of 15 minutes. During this run-in, check ductwork

for any leaks and repair as necessary.

Balancing

1. Adjust fan to the design CFM using either the

Manual or Remote Fan CFM Adjustment method

listed below.

2. Attach a manometer or magnehelic to the differen-

tial pressure ports in the pneumatic tubing leading

to the high and low side of the inlet air probe and

measure the velocity pressure. Adjust and set the

primary maximum airfl ow as necessary to meet

job site requirements. See Table 2, Airfl ow vs.

Velocity Pressure chart. This chart, with different

inlet sizes, is also located on the side of the equip-

ment.

3. If balancing dampers are present, adjust and set

proportionally to desired position. To minimize

noise levels, and prevent premature ECM motor

failure, leave these dampers in the most open posi-

tion possible.

4. The maximum primary air balance may be checked

using the optional radiated sound damper, or by

suspending a sheet of notebook paper over the

inlet using a small psiece of tape. If the damper or

notebook paper is blowing out of the unit, the pri-

mary maximum airfl ow is too high. If the paper or

damper is being pulled into the unit, the maximum

primary airfl ow is too low. Optimum balance is

achieved when the damper or paper hangs straight

down.

FIGURE 2 - ETPWM BOARD LAYOUT

24 volts AC

16A&B

24 volts A/C

15A&B

“G” activation line

Signal common

PWM outputManual speed

adjustment

Common test loop

VDC test loop

Analog input 2-10 VDC

Remote

Manual

umper

LD13841

Loading...

Loading...