JOHNSON CONTROLS

9

FORM ET130.13-NOM3 (708)

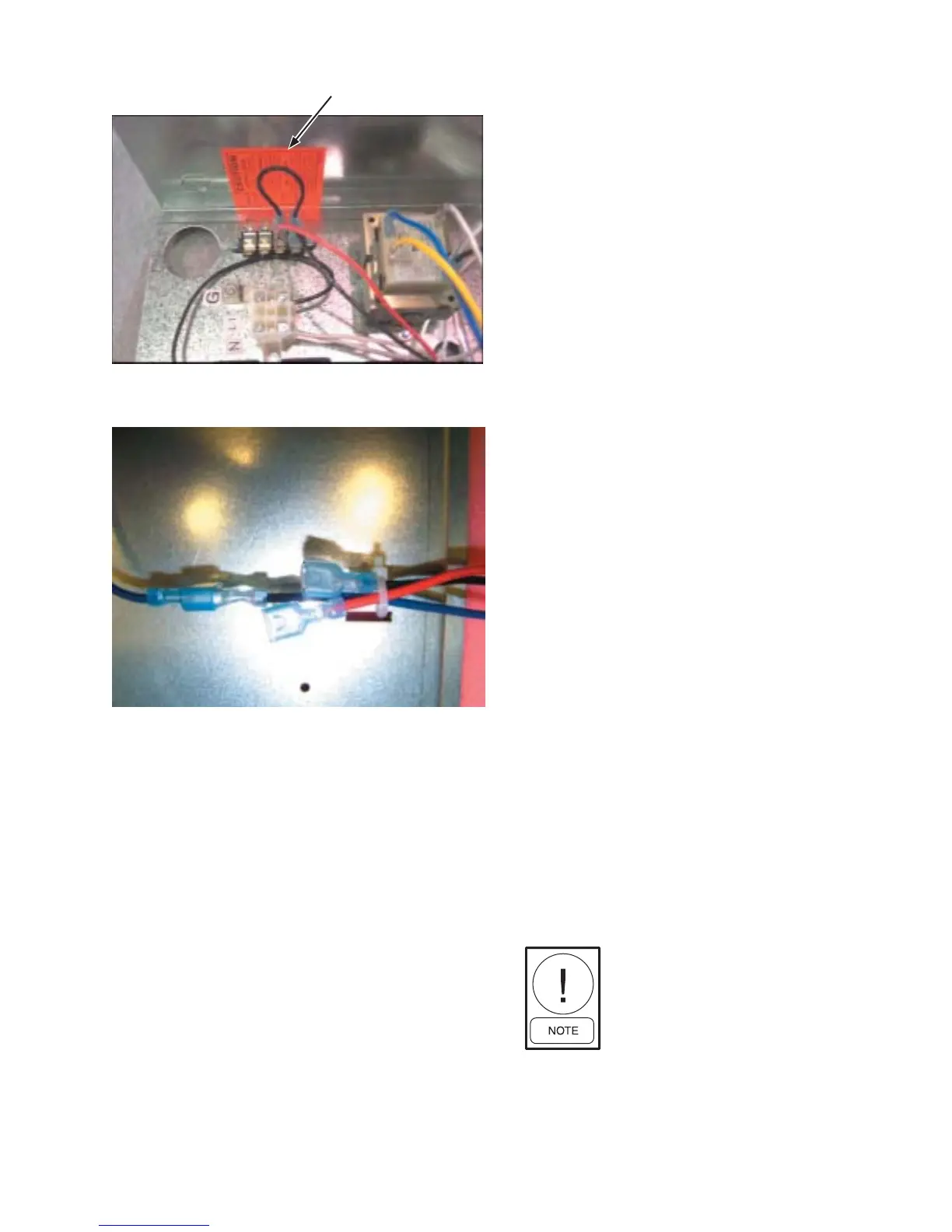

FIGURE 1A - FAN SPEED CONTROL WITH JUMPER

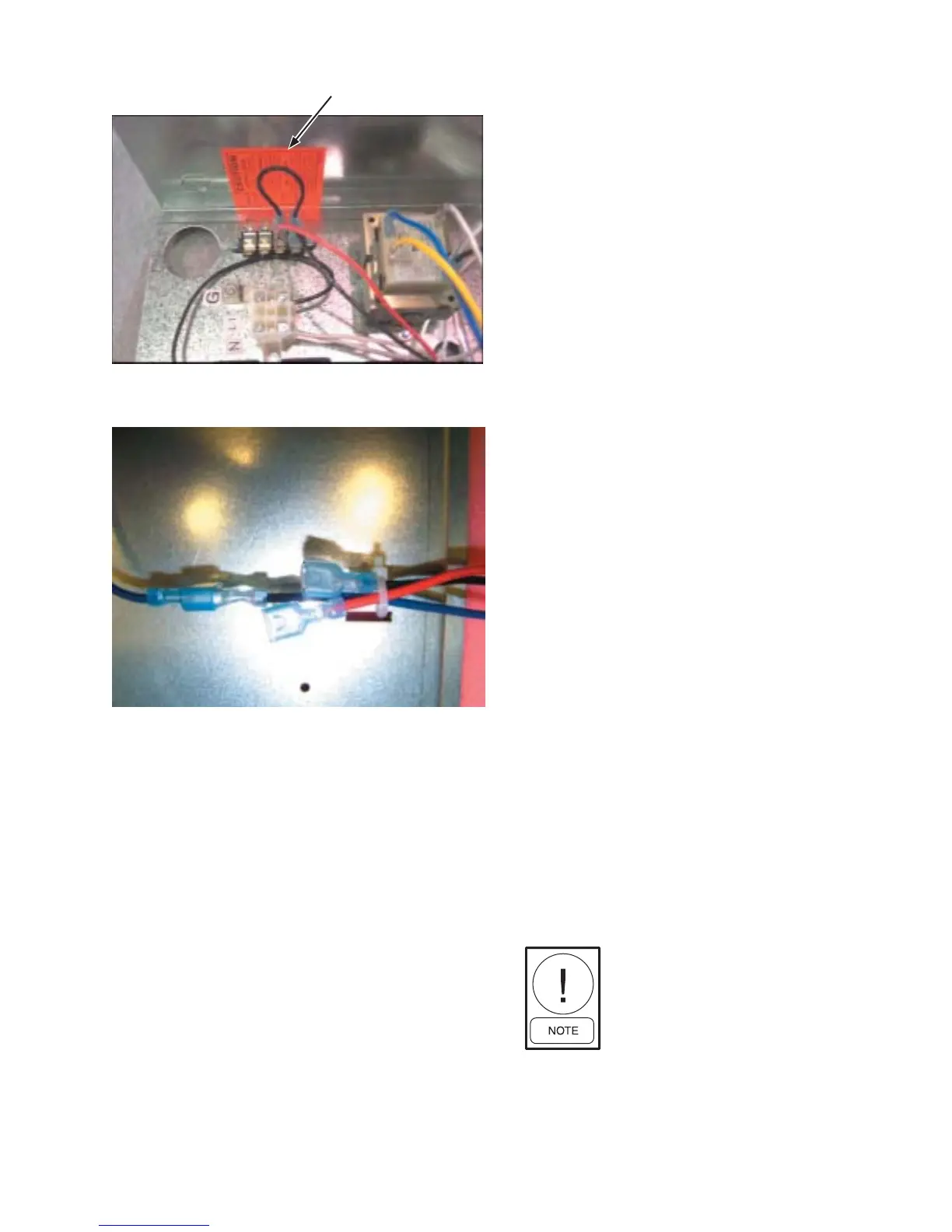

FIGURE 1B - WIRE TO WIRE FAN SPEED SELECTION

Series Flow, PSC Motor with SCR

1. Make sure that the motor speed is at maximum by

turning the potentiometer located on the Fan Speed

Control (SCR) all the way clockwise.

2. Energize motor and let motor operate for a mini-

mum of 15 minutes. During this run-in, check

ductwork for any leaks and repair as necessary.

3. If remote balancing dampers are present set them

to full open.

4. Attach a manometer or magnehelic to the differen-

tial pressure ports in the pneumatic tubing leading

to the high and low side of the inlet air probe and

measure the velocity pressure. Adjust and set the

primary maximum airfl ow as necessary to meet

job site requirements. See Table 2, Airfl ow vs.

Velocity Pressure chart. This chart, with different

inlet sizes, is also located on the side of the equip-

ment.

5. If balancing dampers are present, adjust and set

proportionally to desired position. To minimize

noise levels, leave these dampers in the most open

position possible.

6. If total airfl ow is too low, de-energize unit and

move jumper to next higher speed.

7. Energize unit and adjust Fan Speed Control (SCR)

for desired total airfl ow.

8. The maximum primary air balance may be checked

using the optional radiated sound damper, or by

suspending a sheet of notebook paper over the

inlet using a small piece of tape. If the damper or

notebook paper is blowing out of the unit, the pri-

mary maximum airfl ow is too high. If the paper or

damper is being pulled into the unit, the maximum

primary airfl ow is too low. Optimum balance is

achieved when the damper or paper hangs straight

down.

Parallel Flow, PSC Motor with SCR

1. Make sure that the motor speed is at maximum by

turning the potentiometer located on the Fan Speed

Control (SCR) all the way clockwise.

2. With primary air valve in the closed position, en-

ergize motor and let motor operate for a minimum

of 15 minutes. During this run-in, check ductwork

for any leaks and repair as necessary.

3. If balancing dampers are present, adjust and set

proportionally to desired position. To minimize

noise levels, leave these dampers in the most open

position possible.

4. If fan airfl ow is too low, de-energize unit and move

jumper to next higher speed.

5. De-energize motor and perform minimum and

maximum primary air balance. See Table 2, Air-

fl ow vs. Velocity Pressure chart. This chart, with

different inlet sizes, is also located on the side of

the equipment.

An extra jumper is required on units

with 480 VAC motors. See wiring dia-

gram attached to unit.

JUMPER

LD13840

LD13848

Loading...

Loading...