JOHNSON CONTROLS

11

FORM ET130.13-NOM3 (708)

Manual Fan CFM Adjustment

1. Verify that the jumper on ETPWM board is in the

“MAN” position (shipped from factory in Manual

mode)

2. Connect voltmeter to wire loop VDC (+) and wire

loop COM (-).

3. Determine the DC voltage for required airfl ow from

the Fan Calibration Curve supplied on the side of

the equipment. Use the bottom (5 to 10 volts DC)

scale on the chart. An example Fan Calibration

curve is shown in Table 3; however, the curve on

the side of the equipment should be used in deter-

mining the voltage.

4. Using a 1/8” fl at bladed screwdriver, adjust the

manual speed potentiometer, labeled SPD, to

obtain the required voltage. Clockwise increases

airfl ow, counterclockwise decreases airfl ow.

5. Do not set the voltage lower than 5.1 VDC or

higher than 9.9 VDC or motor may experience

starting problems.

6. Do not set the balance voltage outside limits of the

voltage/CFM curve or erratic motor operation and

eventual failure may result.

Remote Fan CFM Adjustment

1. Relocate the jumper on ETPWM board to the REM

position.

2. Determine the DC voltage for required airfl ow from

the Fan Calibration Curve supplied on the side of

the equipment. Use the top (2 to 10 Analog Input

Volts DC) scale on the chart. An example Fan

Calibration curve is shown in Table 3; however,

the curve on the side of the equipment should be

used in determining the voltage.

3. Remotely adjust the external voltage source to the

desired volts DC for required airfl ow.

4. Do not operate motor at control voltage lower than

2.1 VDC or higher than 9.9 VDC or motor may

experience starting problems.

5. Do not operate motor at control voltage outside

limits of the voltage/CFM curve or erratic motor

operation, and eventual failure may result.

Status LED

When the motor is running, the LED alternates between

CFM and RPM indications. In the RPM mode, LED

turns on for a period of approximately 220 microseconds

at a rate of 36 pulses per revolution. This mode lasts

for ten seconds. Due to the rapid rate, LED will appear

to be dimly lit, not fl ashing. As RPM is increased,

brightness will increase. In the CFM mode, the LED

will fl ash slowly, and at maximum brightness, once for

every 100 CFM. Accuracy is +/- one fl ash. LED will

then return to RPM mode, and cycle will repeat.

MAINTENANCE

Factory Provided Damper Actuator

Equipment may be supplied with a fi eld

or factory mounted damper actuator.

If actuator is factory provided, see

ACT24 Actuator IOM available at

www.enviro-tec.com. See Table 1 for

maximum wire lengths for control

voltage.

Damper Shaft

There is an indicator on the end of the damper shaft that

can be used to determine the position on the damper

blade. If the indicator is horizontal, the damper is

completely open.

Motor/Blower

Fan powered terminal unit motors are equipped with

permanently lubricated bearings and require little or

no maintenance. The frequency of required cleaning

is dependent on the operating hours of the system,

fi lter maintenance and effi ciency as well as dirt load.

Periodically inspect the motor and blower-housing wheel

for accumulation of dust and clean as necessary.

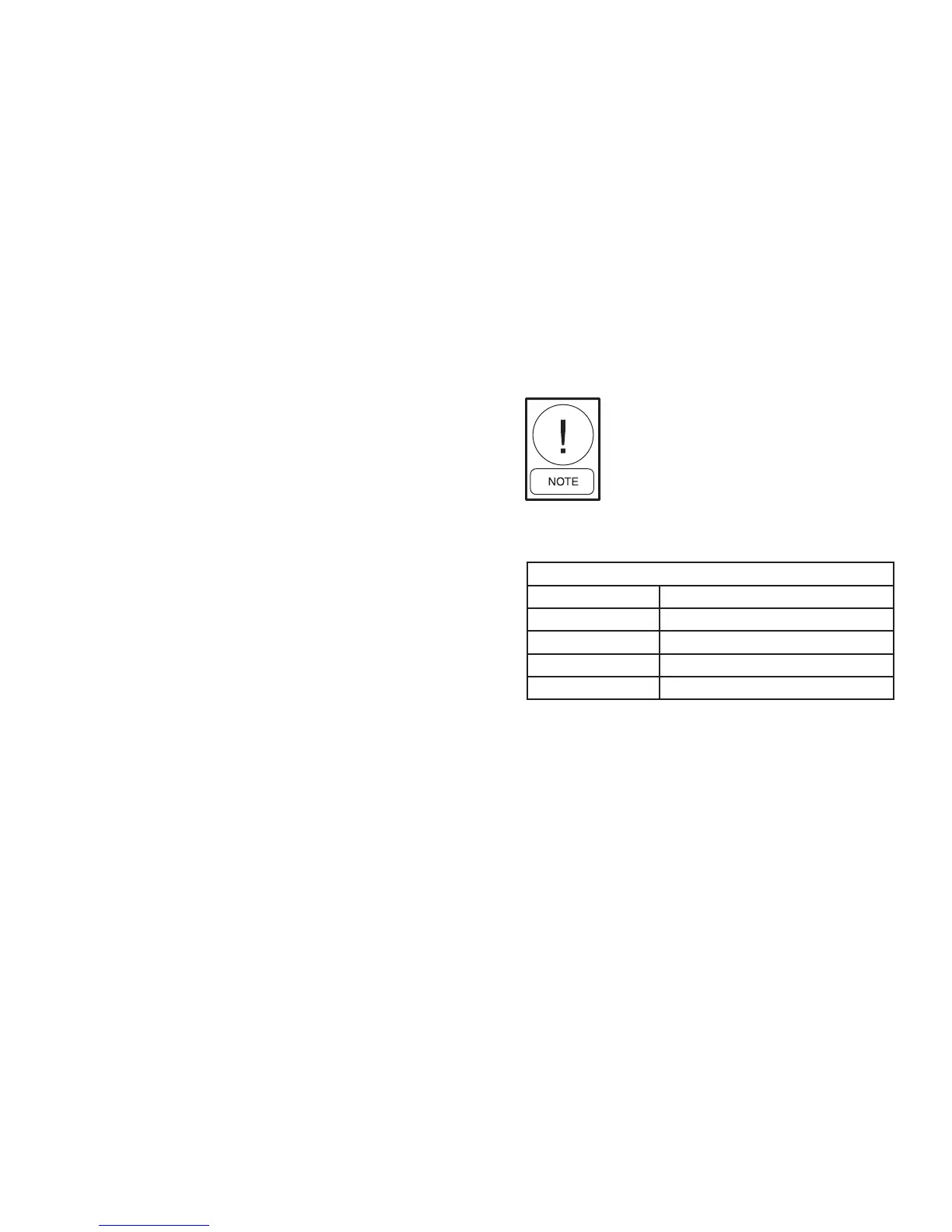

TABLE 1 - MAXIMUM WIRE LENGTHS

WIRE SIZE MAX FEET

16 GA 1225 FT

18 GA 725 FT

20 GA 400 FT

22 GA 200FT

Loading...

Loading...