10

Draining the air filter

Drain the air filter regularly by pressing the drainage valve

upwards. The filter is also drained automatically when the

compressed air is switched off. A hose can be connected to the

drainage valve if required (to discharge the water in a convenient

place).

Cleaning the air filter

• Unscrew the filter bowl

• Unscrew the separator disc

• Clean the filter

• Blow clean the filter from the inside out

• Fit back the filter

• Fit back the filter bowl

Ejector

The pneumatic system includes an ejector that serves to create

the vacuum which locks the grinding disc and driver plate to each

other. The ejector does not normally need any maintenance. If it

needs to be cleaned, simply remove the connection nipples and

blow clean the ejector housing.

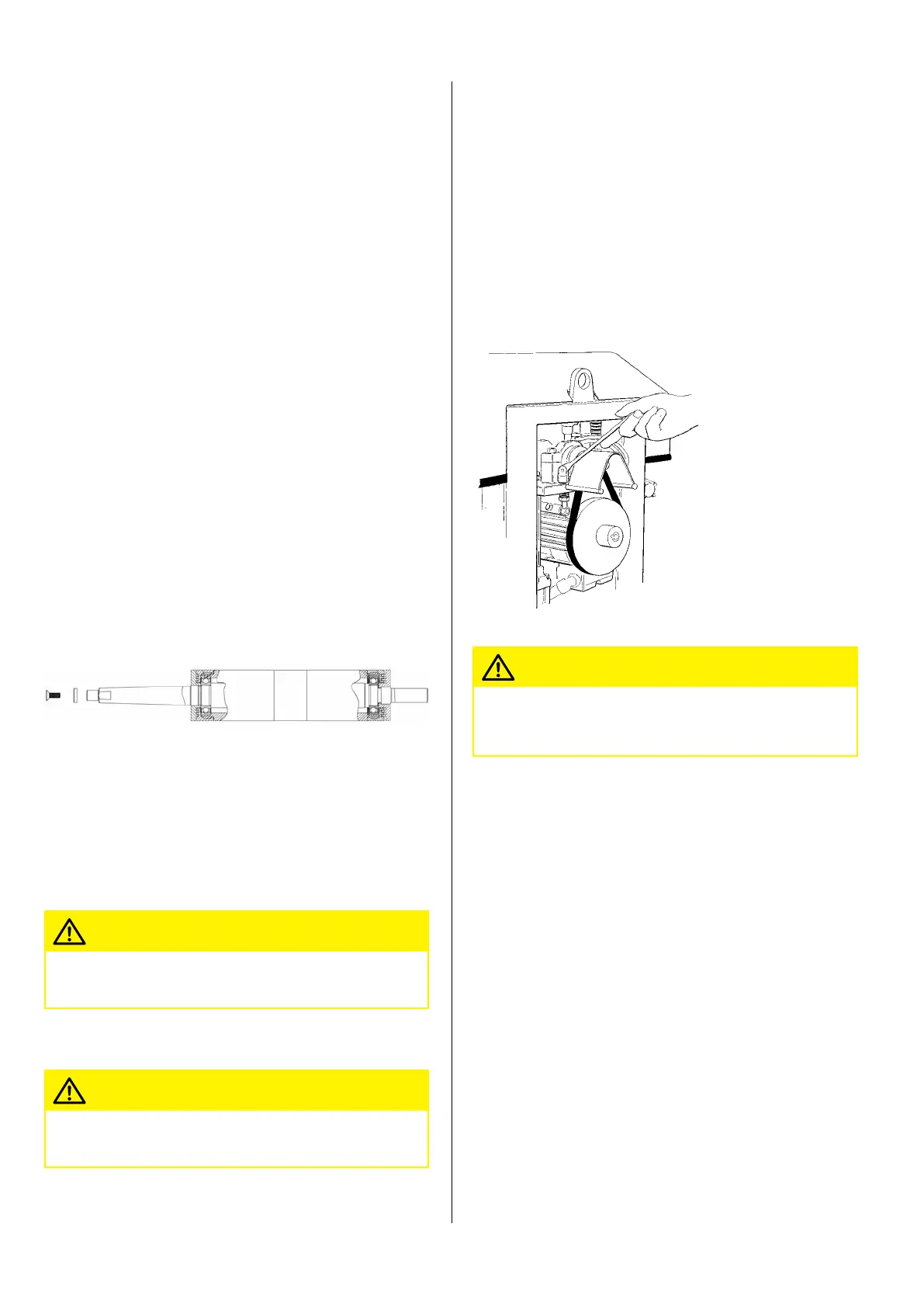

Grinding spindle

The spindle is manufactured with great precision. Rough handling

can reduce the service life of grinding wheels. Care must there-

fore be taken when changing the grinding wheel. If necessary, use

the puller to remove the grinding wheel, product code 87005058.

Before fitting a new grinding wheel, lightly grease the spindle. The

bearings of the grinding spindle are permanently lubricated and

does not normally need further lubrication.

Dismantle, overhaul and assemble.

The outer nut threads are different. The one at the front end

(87000780) has a right hand thread, turn counter-clockwise to

open. The one at the back (87000781) is a left hand thread.

The inner nuts are all right hand thread.

To remove the ball bearings, pull them off. Use a puller. Check

that the spindle shaft is in good condition. If the shaft has run out

larger than 0,02 mm, replace it.

Vibrations will effect the grinding result and the life of your

diamond grinding wheel.

IMPORTANT

When mounting the bearings back on to the spindle. Press them

back. Use a sleeve.

Fill each of the new ball bearings to 25% with the recom-

mended grease. – Do not overfill the bearings!

IMPORTANT

Note the direction of the disc springs.

Grinding disc and driver plate

Make sure that the surfaces between the grinding disc and the

driver plate are always clean. The O-ring between the two plates

must be checked regularly. Damage to the O-ring will reduce the

strength of the vacuum. Small amounts of oil can be used to

prevent corrosion.

Protective bellows

The bellows serve to protect the tubular ball guides from dirt.

Make sure that they remain in good condition in order to prevent

grinding dust from entering and damaging the tubular ball

guides.

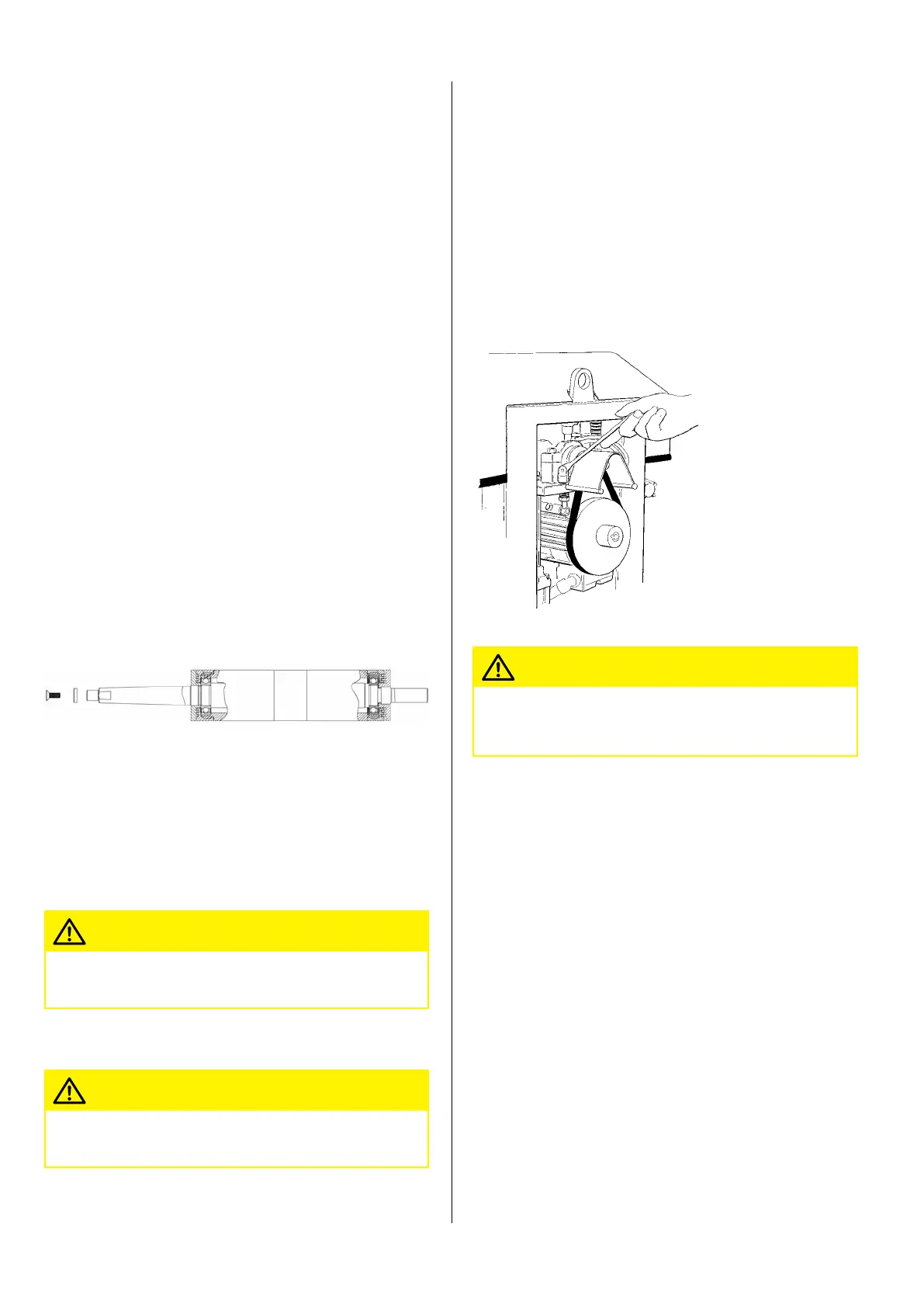

Drive belt

The drive belt between the

motor and grinding

spindle can be tensioned

by adjusting a spring-

loaded screw on the

motor shelf.

It is important for the motor shelf to be correctly adjusted,

otherwise the drive belt can wander on the jockey wheels,

which can result in damage.

IMPORTANT

Loading...

Loading...