4

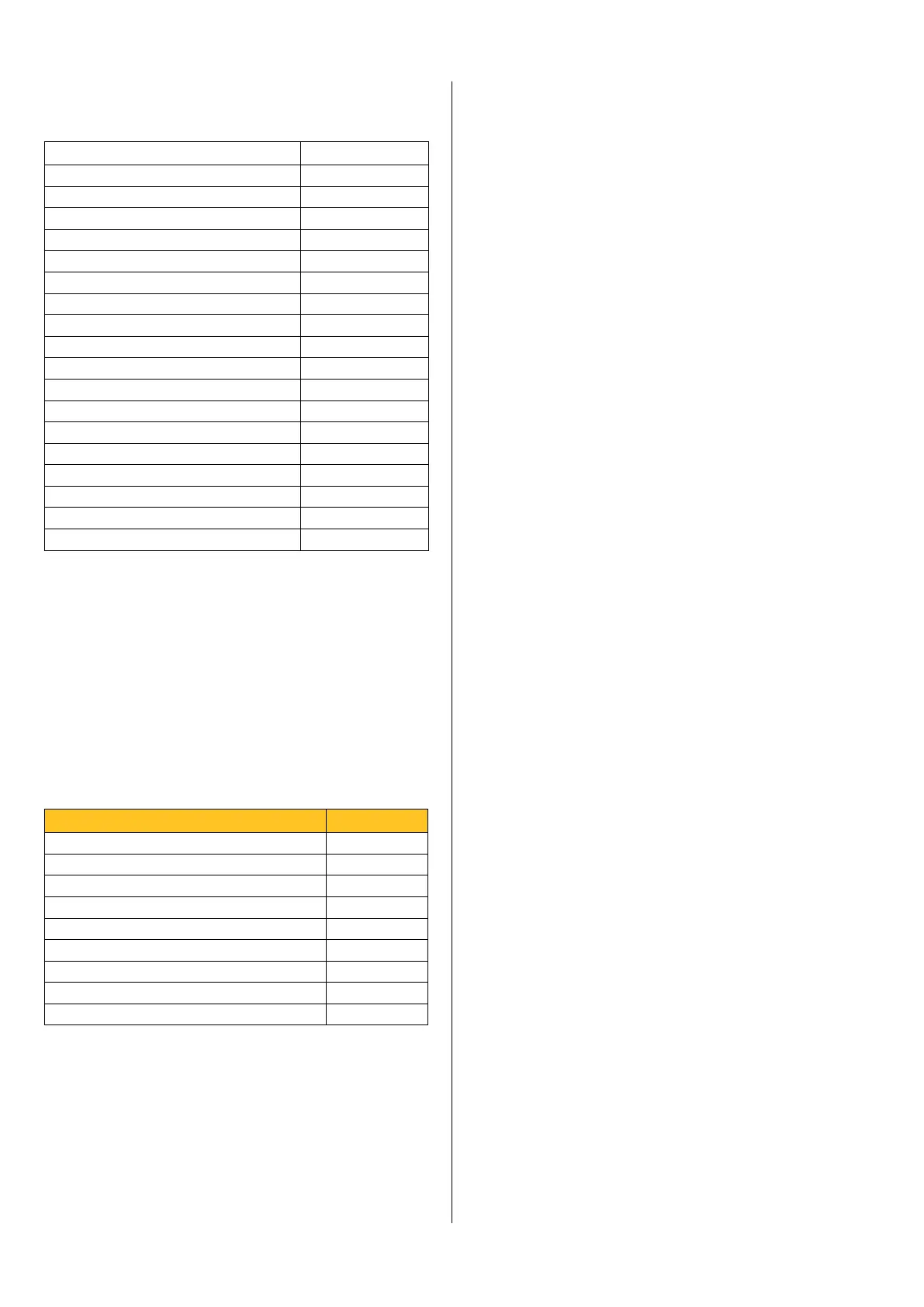

Technical data

Maximum height of drill bit 650 mm

Maximum diameter of drill bit 178 mm

Minimum distance between buttons 3.5 mm

Output, spindle motor 3.00 kW

Output, table drive motor 0.25 kW

Output, cooling-fluid pump motor 0.44 kW

Voltage, working lights (40 W E27) 24 V

Air pressure, minimum 80 psi / 5,5 bar

Air pressure, maximum 101 psi / 7 bar

Air consumption 40 l/min

Speed, spindle (50 Hz) 14,900 r/min

Speed, spindle (60 Hz) 14,900 r/min

Speed, table (50 Hz) 22 r/min

Speed, table (60 Hz) 26 r/min

Capacity of cooling-fluid tank 22 l

Weight, exclusive of packaging 345 kg

Noise level during grinding* 96.5 dB(A)

Sound power level during grinding** 101 dB(A)

Vibration level during grinding*** < 2.5 m/s2

Manufactured: Epiroc Drilling Tools AB, Fagersta, Sweden

* Equivalent continuous A-weighted sound pressure level meas

-

ured at operator’s ear level during grinding. Possible spread due

to measuring method and production factors: 3 dB(A).

** Sound power level established in accordance with SS/ISO 3741.

Possible spread due to measuring method and production factors:

3 dB(A). Average value for frequency range 100-6300 Hz.

*** Vibration measurement according to EN/ISO 8662.

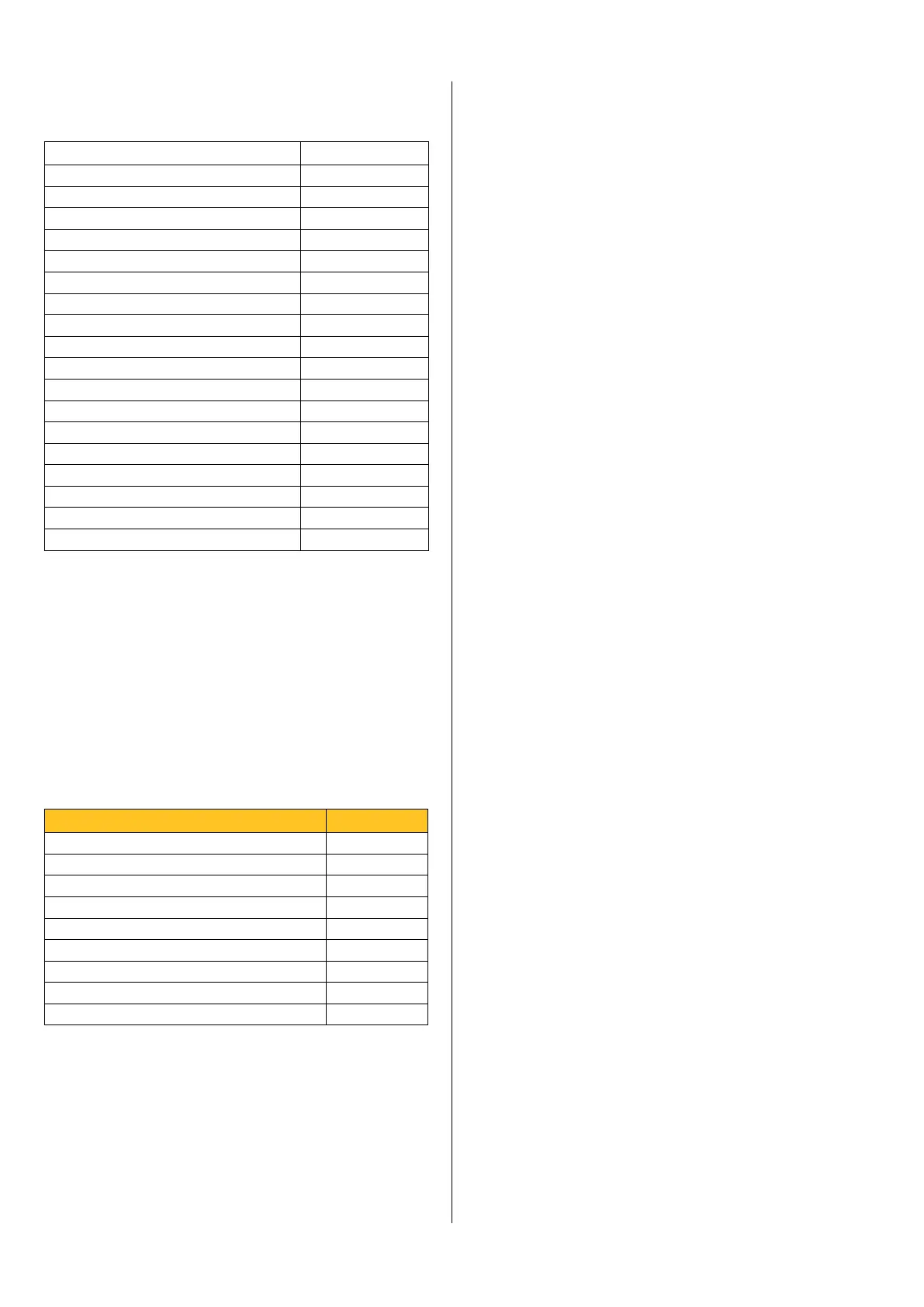

Accessories included

Description Product No�

Goggles 87001967

Puller 87005058

Wrench, 15 mm 87001439

Allen key, 4 mm 87002413

Filter wrench 87004659

Centring cup, 11 mm 87001387

Centering wheel, 16mm 87004760

Rubber feets 87002417

Spare parts manual, printed matter no. 9866 0044 01b

General

The Secoroc BQ3-DTH grinding machine is designed to grind

cemented-carbide buttons and the surrounding body steel in the

same operation using a diamond-coated grinding wheel. The

machine has an automatic feeding device, which makes it simple

to use.

For grinding to be carried out, the machine must be fitted with a

grinding wheel, a centring cup, a bit holder and an indexing ring

to suit the bit that is to be ground.

Applications

The Secoroc BQ3-DTH is intended for grinding DTH, COPROD and

threaded button bits up to 178 mm in diameter.

Technical description

The Secoroc BQ3-DTH consists principally of the following com-

ponent assemblies:

• A driving plate that is rotated by an electric motor via a worm

gear.

• A grinding disc that is placed on the driving plate. When the cen

-

tring button on the feed lever is pressed, an air cushion is created

under the grinding disc to facilitate centring of the button that is

to be ground. When the centring button is released, the grinding

disc is locked in position by a vacuum.

• A main holder, with a bit holder in accordance with the used

shank size.

• A centring device that adopts the centre position automatically

when the centring button is pressed. The centring device is in its

lower position when centering the button.

• A spindle that is rotated by an electric motor via a drive belt.

• An automatic feeding system for advancing the grinding wheel

on to the button. Feeding is effected by a pneumatic cylinder, but

manual feed is also possible.

• A coolant tank with pump to circulate the flushing fluid used to

cool the cemented-carbide buttons and the grinding wheel. Flush

-

ing starts automatically when table rotation starts.

The button to be ground must first be centred directly under the

grinding wheel. Table rotation is then started and the profiled

grinding wheel fed down to the rotating drill bit. The centred

cemented-carbide button rotates inside the profiled groove in the

grinding wheel and is quickly restored to its shape.

Loading...

Loading...