9

For best grinding results and wheel life:

• Centralize the buttons precisely.

• Make sure there is a generous flow of coolant at the point of contact.

• Grind carefully and do not rush.

• Let the machine do the work.

• Do not try to speed up grinding by adding hand pressure to the

feed lever.

• Use original grinding wheels only.

• Use recommended pressures.

Grinding hints

The rate of bit wear depends on the rock formation, and is highest

in rocks with a high quartz content. A suitable grinding interval

should be determined according to the rate of bit wear. It is more

economical to regrind too early rather than to suffer poor penetra-

tion rates and risk damaging the drill bit through overdrilling. A

few hints about the care of drill bits:

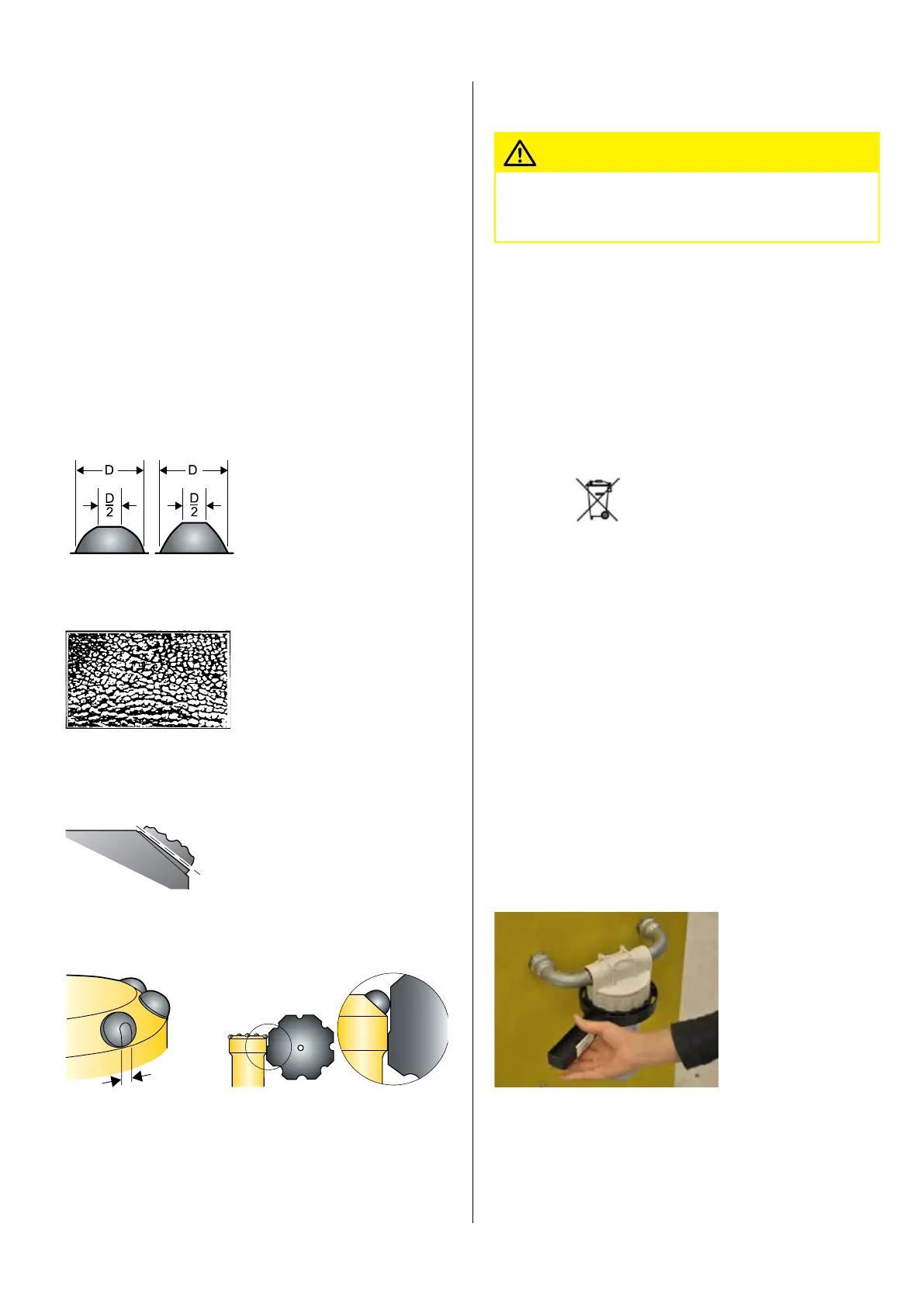

When to regrind

Button bits should be re ground

when the pene tration rate drops,

or if any of the cemented-carbide

buttons are damaged (fractured

buttons should be ground flat). It

is both practical and economical to

redress the buttons when the wear

flat reaches about 1/2 of the diameter of the button.

Look out for “snake skin“

If microscopic fatigue cracks – so-

called “snake skin“ – begin to

appear on the cemented car bide

buttons, the cracks must be ground

away. In any event, bits should be

reground after 300 metres of

drilling at the most. This should be

done even if there are no visible signs of wear and the penetra-

tion rate continues to be good. If snake -skin is not removed, the

cracks will deepen and ultimately result in button fracture.

Always grind broken buttons flat

A drill bit can remain in service as long

as the gauge buttons maintain the

diameter of the bit. Fractured buttons

must always be ground flat to prevent

chips of cemented carbide from

damaging the other buttons.

Avoid grinding the perimeter

2 mm

Min

0,5

Gauge button anti-taper has to be removed by grinding, although

excessive reduction of the bit diameter should be avoided. Leave

about 2 mm of the wear flat.

If necessary, remove some of the bit-body steel below the gauge

buttons, so that a clearance (taper) of 0,5 mm is maintained.

Make sure that the flushing holes are open.

Maintenance

• Before attempting service or repair work on the machine,

ALWAYS switch off and disconnect the electricity supply and

the compressed air supply.

CAUTION

Cleaning

Keep the machine clean at all times. This is the cheapest and easi-

est way to maintain the machine.

Lubrication

Most bearings and bushings in the machine are permanently

lubricated and do not normally need any maintenance. Use the

grease nipples to lubricate moving parts.

Follow our recommendations found in this instructions, section

"Recommended lubrication and cooling liquids".

Disposal

A used machine must be treated and disposed in such a way that

the greatest possible portion of the material can be recycled and

any negative influence on the environment is kept as low as pos-

sible, and with respect to local restrictions.

Cooling liquid

Particles of cemented carbide and steel gradually accumulate in

the sedimentation tank. Empty and clean out the tank regularly. If

the machine is used every day, the sedimentation tank should be

cleaned out at least once a week. Since the water in the tank con-

tains particles of cemented carbide, local regulations (in respect of

water contamination) must be observed when it is emptied.

Fill the sediment tank with new fluid consisting of a mixture of

cooling concentrate and water (mixing ratio 4-8%). Apart from

cooling the grinding wheel and cemented-carbide buttons, the

cooling fluid serves to prevent rust in the machine.

If the machine is not going to be used for some time, the cooling

system should be drained. If the machine is not going to be used

for a long time, it should be oiled generously.

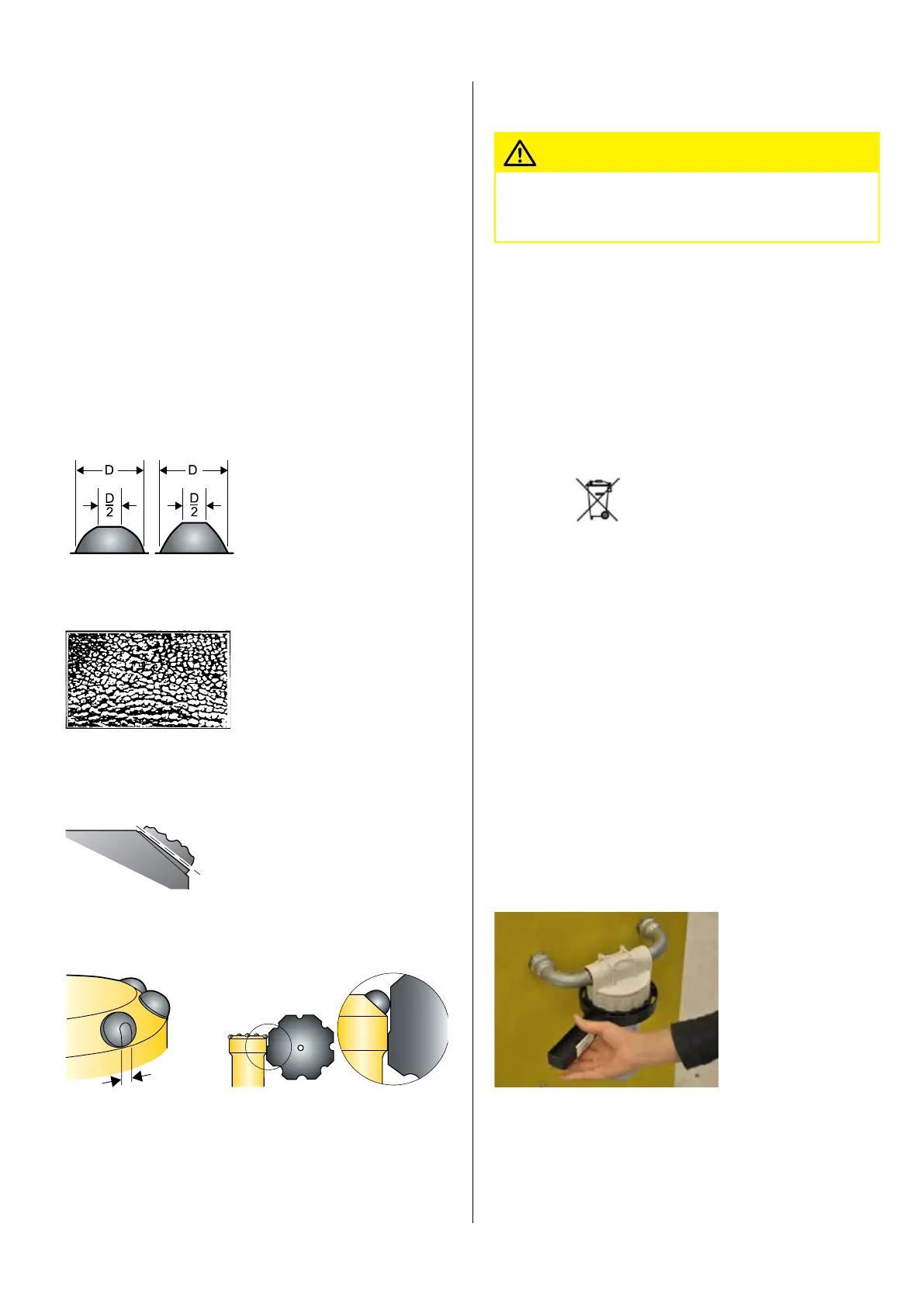

Water filter

Use the wrench to open and/or close the cup.

Air filter

The air filter prevents particles of dirt and also water from enter-

ing the pneumatic system. It should be drained and cleaned

regularly. The water level in the bowl must not be allowed to rise

as high as the separator disc.

Loading...

Loading...