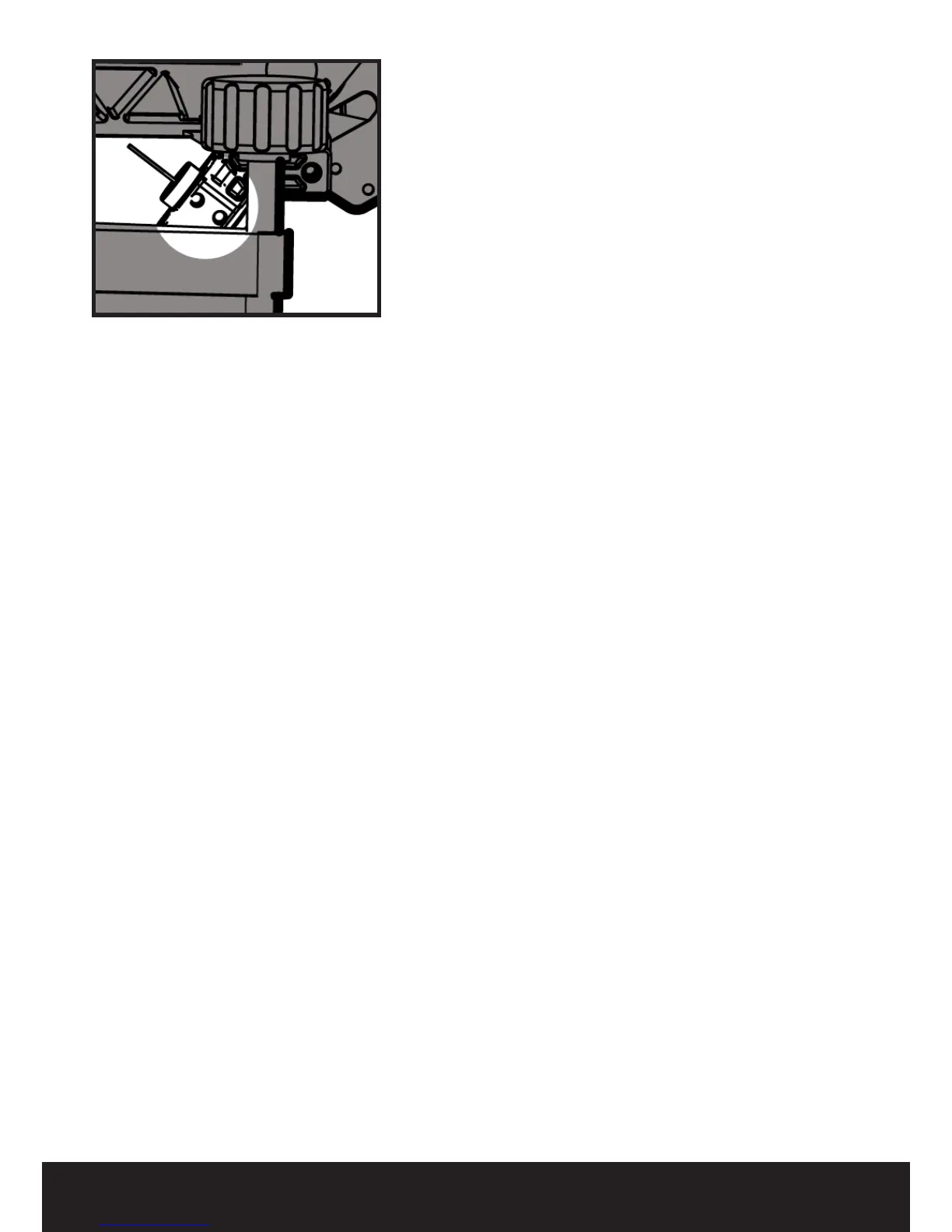

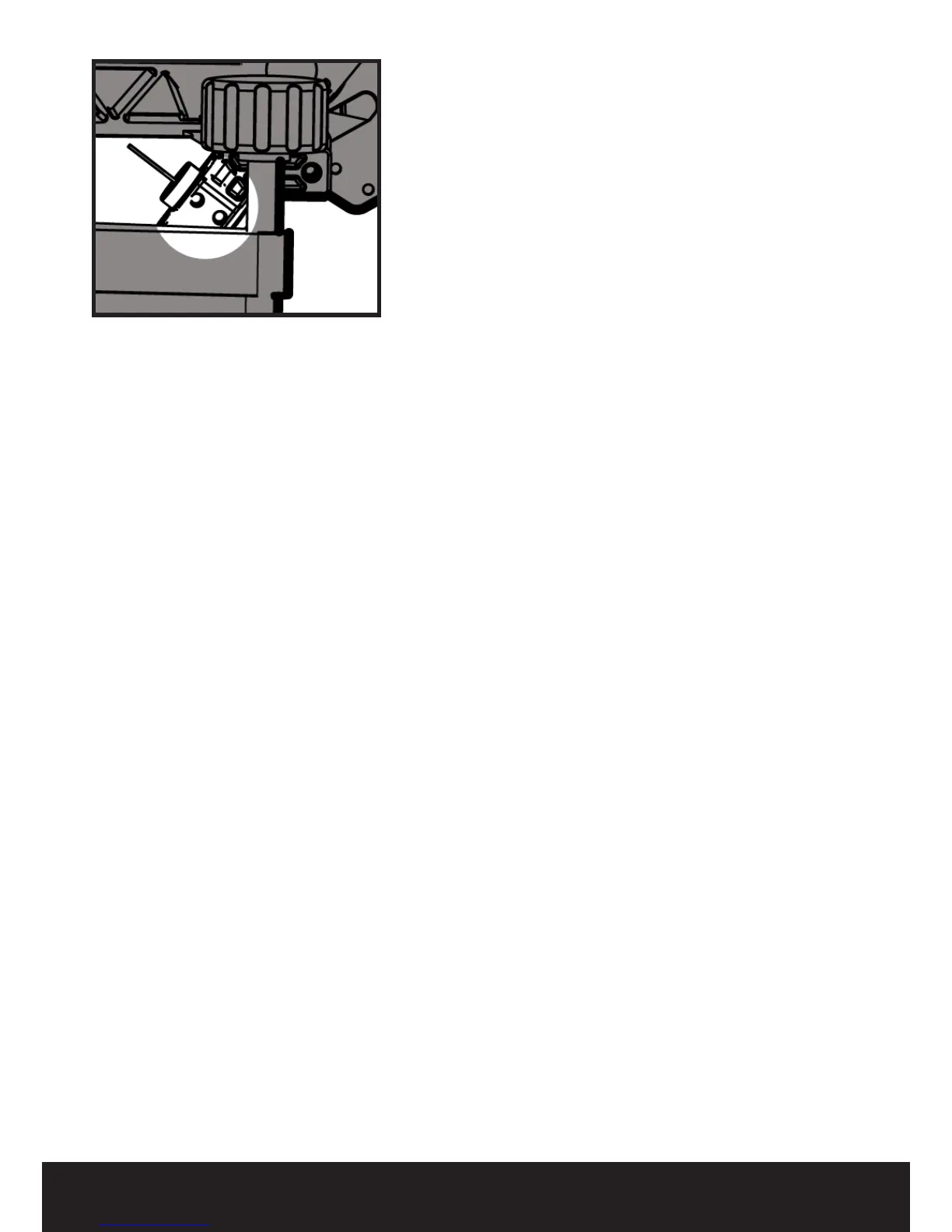

Four laser module mounting/adjustment screws

are provided. Two hex socket grub screws are

positioned on the LH side of the laser housing

(Fig 25), and one on the RH side of the laser

housing. A nal cross-headed xing screw is

to be found just below the laser lens. These

screws gently hold the laser module in place and

on alignment by bearing on the laser modules

casing. It is important that during any adjustment

the pressure on the laser module casing is

maintained as closely as possible to the factory

setting. Do not over tighten any one screw –

damage to the laser casing could result.

B) Adjusting the Angle of the Laser Guide

1) Loosen the cross-headed screw.

2) Loosen the single screw on the RH side of the

laser housing ¼ a turn.

3) Turn the laser element in the desired direction

to adjust the laser angle.

4) Retighten the adjustment screws.

C) Aligning the Laser Beam

1. Loosen the cross-headed screw.

1) Loosen the right hand screw ¼ of a turn.

2) Use the two adjusting screws on the LH side

of the laser housing.

3) Adjust both screws until laser alignment is

achieved.

4) Retighten right hand screw.

5) Retighten the cross-headed screw

Note: Use only the correct sized hex key when

adjusting the grub screws. Turn one screw at a

time and only ¼ turn in either direction before

checking laser alignment. Maintain as far as

possible the original factory pressure setting that

these screws exert on the laser module

LUBRICATION & CLEANING

Note

Any maintenance must be carried out with the

machine switched off and disconnected from the

mains power supply.

All motor bearings in this machine are lubricated

for life. No further lubrication is required.

Fig 25

ERBAUER 24V 165MM SINGLE BEVEL MITRE SAW

Loading...

Loading...