6 BASIC WELDING GUIDE

0463 815 101 - 54 - © ESAB AB 2021

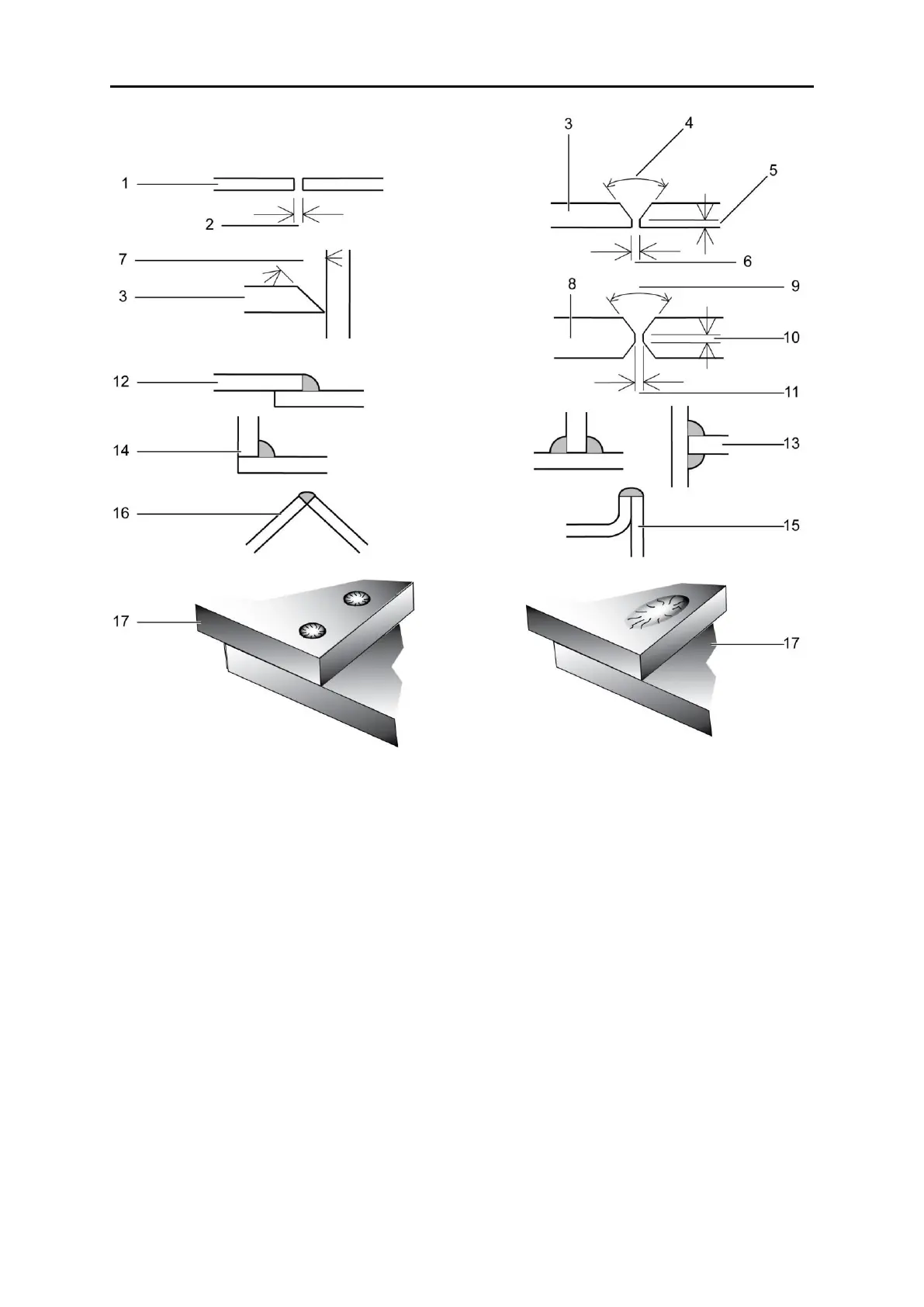

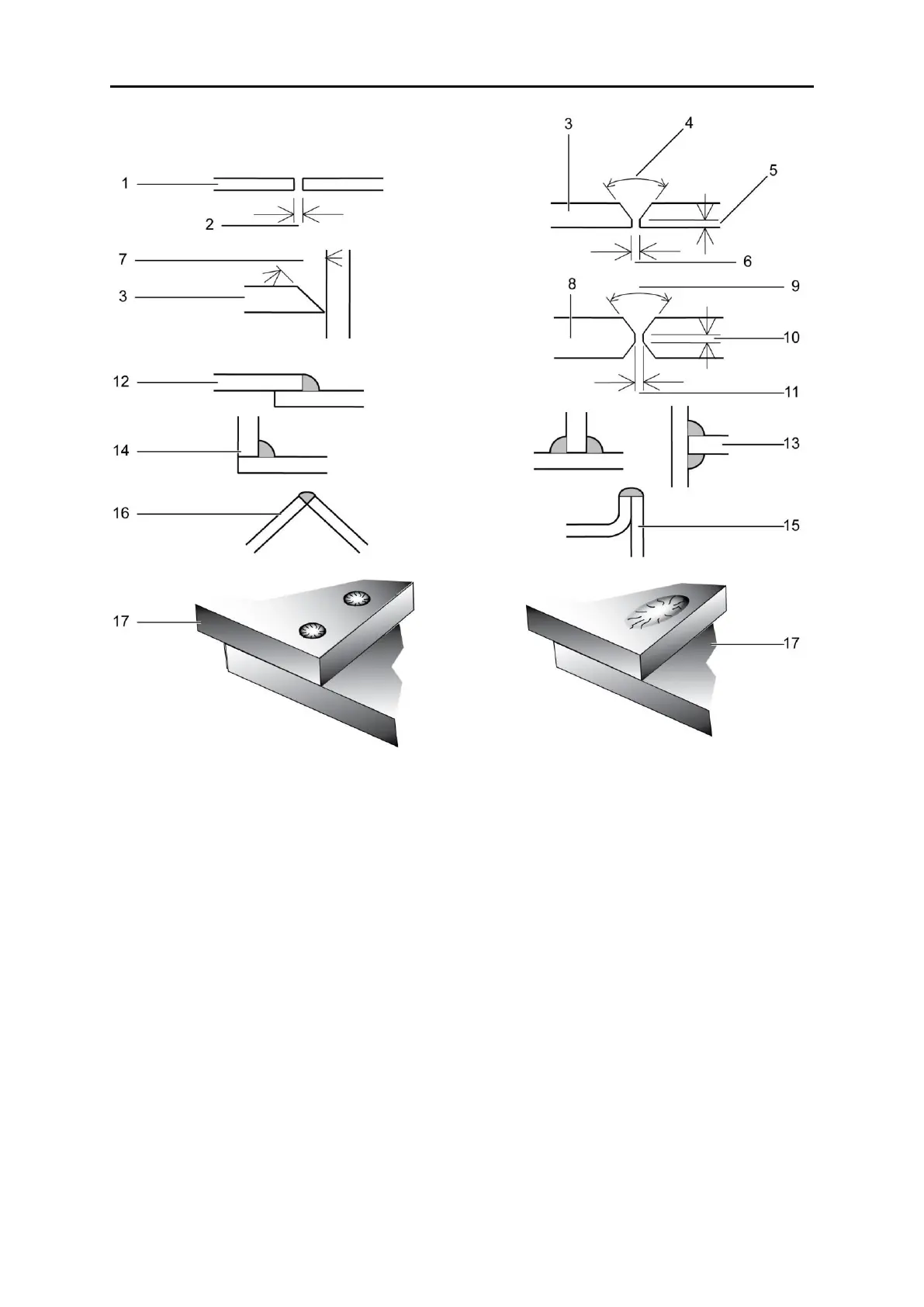

Figure 56: Typical joint designs for arc welding

10 Maximum 1/16 in. (1.6 mm)

2 Gap varies from 1/16 in. (1.6 mm) to 3/16 in. (4.8

mm) depending on plate thickness

13 Tee joint (Fillet both sides of the joint)

5 Maximum 1/16 in. (1.6 mm)

A: Gap varies from 1/16 in. (1.6 mm) to 3/16 in. (4.8 mm) depending on plate thickness

B:Not less than 70°

C: Maximum 1/16 in. (1.6 mm)

D: 1/16 in. (1.6 mm) E: Not less than 45°

F: Not less than 70°

G: Maximum 1/16 in. (1.6 mm)

H: Maximum 1/16 in. (1.6 mm)

Loading...

Loading...