11

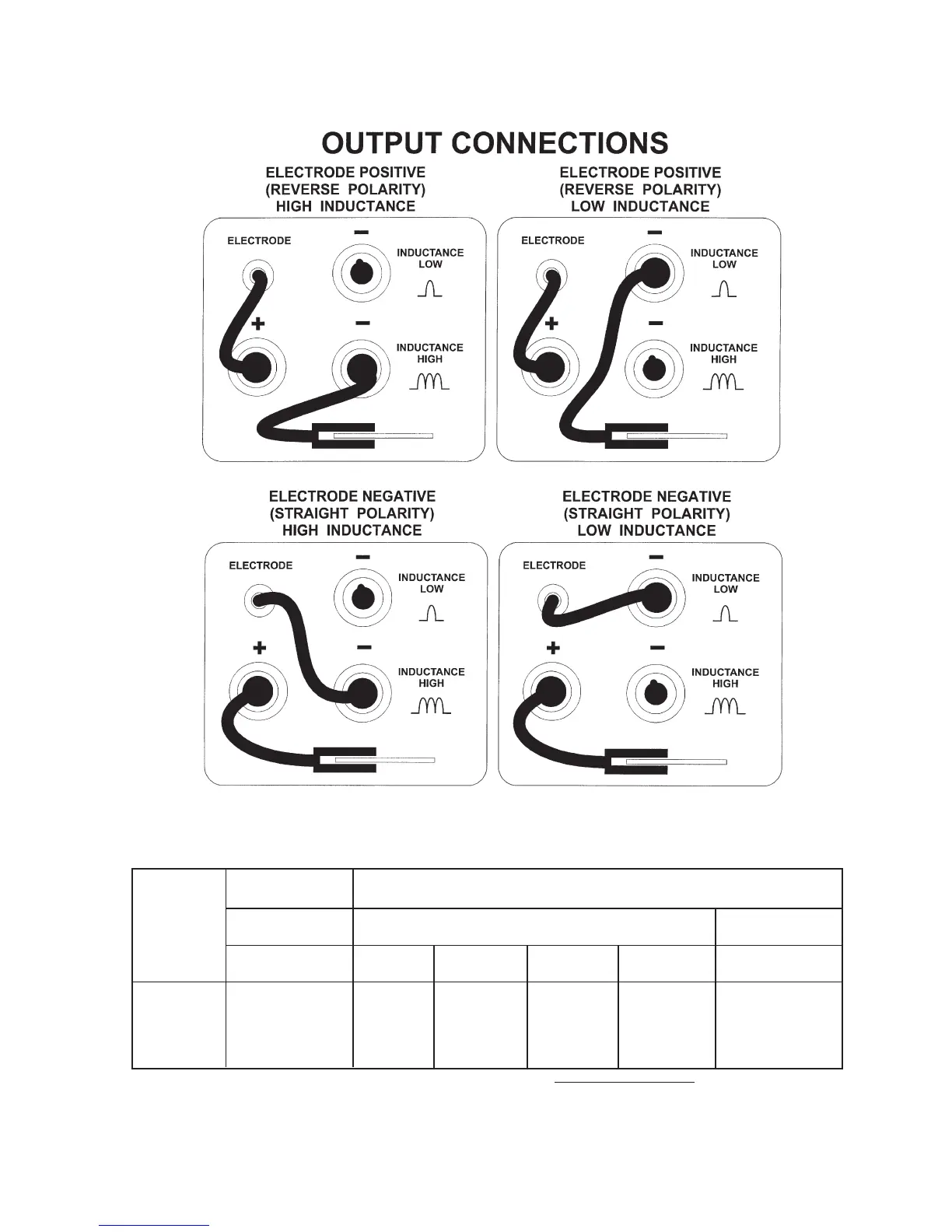

Recommended Output Inductance Tap Connections for Short-Arc Welding

Notes: The above chart shows the recommended output inductance tap connection for Mig Short Circuiting Transfer.

For Mig Spray Arc Transfer (stainless or carbon steel) - use low tap

For Flux Cored Wire (all types) - use low tap

NR - Not Recommended

* The best connection (high tap or low tap) depends on the specific welding application and personal preference.

Stainless Steel

Solid Wires Carbon Steels Solid Wires

Helium/Argon Based

Shielded Gases Argon Based Shielding Gases CO

2

Shielding Gas

Welding .023" .030" .035" .045"

Current All Wire Diameters (0.6mm) (0.8mm) (0.9mm) (1.2mm) All Wire Diameters

≤ ≤

≤ ≤

≤ 100 amps high tap high tap high tap high tap high tap low tap

125 amps high tap high or low* high or low* high or low* high or low* low tap

150 amps high tap N R low tap low tap low tap low tap

≥≥

≥≥

≥ 200 amps high tap N R N R low tap low tap low tap

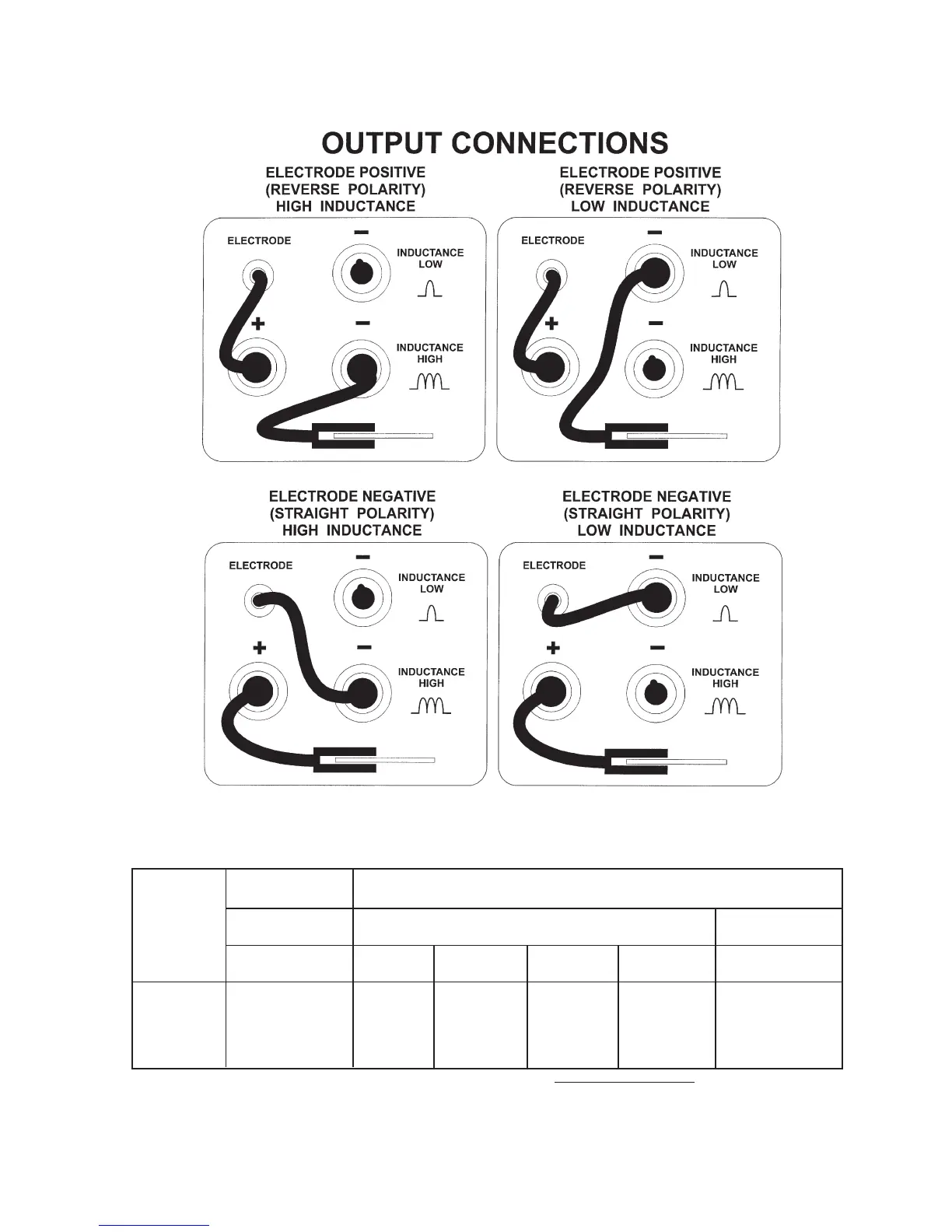

Figure 1 - Output Connections and Guidelines

Loading...

Loading...