9

Installation

Recommended Wire Sizes (inches)

MigMaster 210

Mild Steel .023 -.035

Stainless Steel .030 - .035

Cored (gasless) .035

Unpacking

After unpacking, fit the wheels and gas bottle rack according to

the guide shown on page 13. Remove any covers over the

machine to ensure adequate cooling.

Electrical Connections

First make sure that the power supply is appropriately

fused (see Technical Data on page 8). Check that the

unit is connected for the appropriate main voltage. As

standard, the MigMaster 210 is connected for 230v-1

phase supply. Reconnecting should be done according

to the wiring diagrams on page 15. When connecting the

power plug, it is absolutely essential that the green/yellow

wire of the primary cable is connected to the earth screw

of the plug. The remaining two wires, live and neutral,

should be connected to the remaining two terminals in

the correct order.

Electrical connections should be made by a fully

qualified person.

Return Welding Cable And Clamp

The return cable should be firmly connected to the required

outlet terminal on the front of the machine. The clamp

should be clamped securely to the workpiece. Ensure all

connections are clean and tight to avoid welding defects.

Connecting The Welding Gun (See Fig. 1, pg.9)

The gun is connected to the Euro connector on the front

of the machine. Carefully align gas connection tube and

trigger connection pins with Euro adaptor on Mig gun.

Push in and tighten the lock nut. Be careful to line up gun

fittings correctly before tightening to avoid damaging

trigger pins and gas connection. Ensure that the Mig gun

is fitted with a wire conduit and contact tip suitable for the

size and type of wire being used. Refer to the Gun Manual

for spare parts

Feed Rolls

Make sure that the correct feed roll and grooves are used

for the dimension and type of wire being used. Each feed

roll has grooves for two dimensions of filler wire. The

feed roll

must be fitted with its size marking facing you.

The feed roll can be changed or replaced by removing the

screw in the centre of the hub.

“V’” groove rolls as supplied as standard for solid wire,

and serrated rolls for use with cored wire to ensure positive

feeding.

Welding Wire

Select a welding wire of the appropriate type and

size for the job at hand. See ESAB’s consumable

catalogue, available from your nearest ESAB Dis-

tributor, for a range of quality welding filler materials

and their recommended welding parameters.

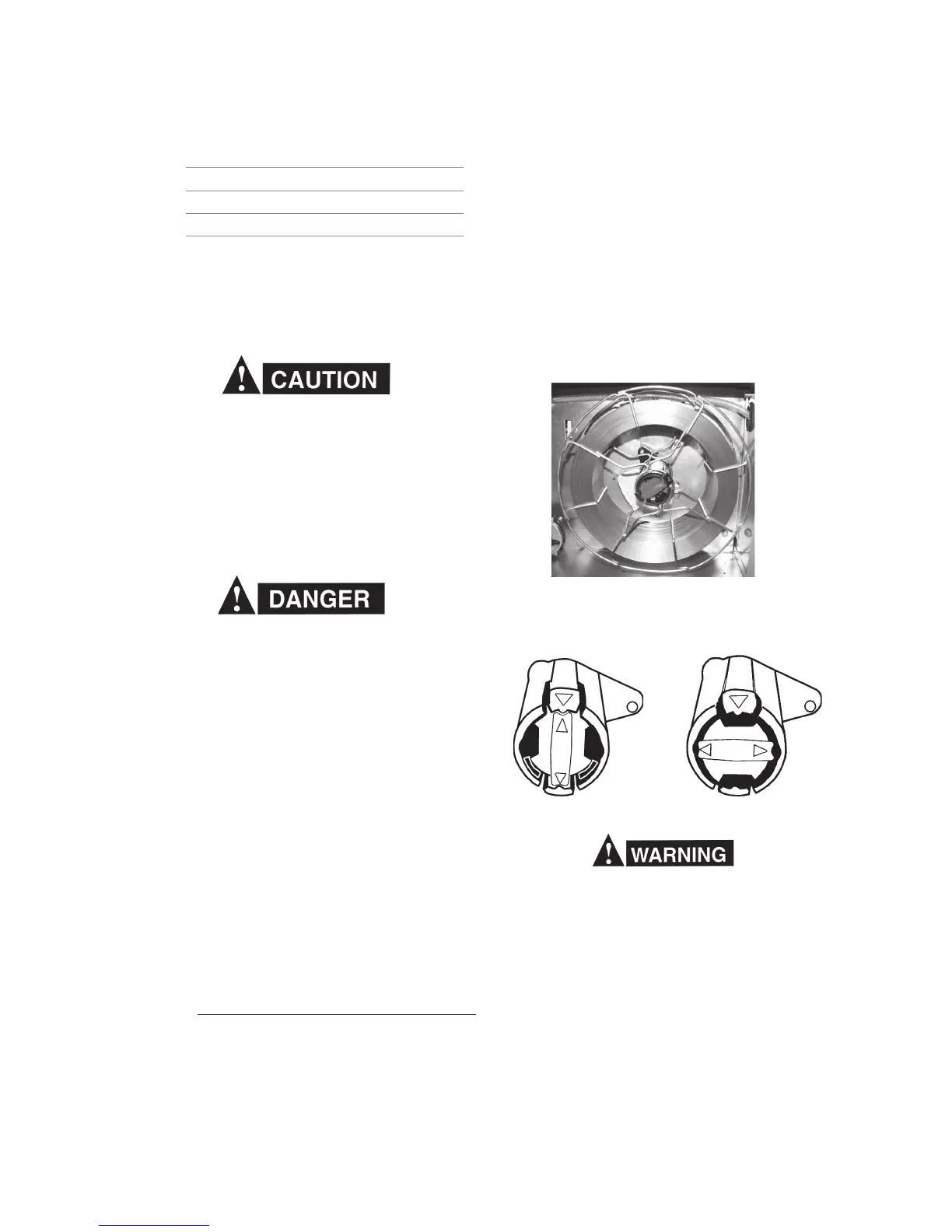

Fit the reel on to the hub so that the wire runs off at the

bottom into the wire guide. Two catches on the hub hold

the reel in place. It is in the lock position when the arrows

on the hub align with the arrows on the two catches (see

Fig. 2). To disengage the locking mechanism, twist the

center knob to the left (see Fig. 3). On a new reel, the

outer end of the wire is inserted through a hole and bent

over.

As with any work area, make sure safety glasses

with side shields are worn when handling or

changing wire or clipping wire off at the spool or

at the end of the torch. Hold onto the wire coming

off the spool with one hand before clipping.

Serious eye injury can result due to the springi-

ness of the wire which can quickly unravel, or a

cut wire end which may shoot across the room.

When loosening the wire from the hole, take care to hold

the coil so that it does not spring out and unravel. Cut off

the bent end of the wire, straighten the tip and then file off

any sharp edges so that the wire can run easily through

the soft wire guide of the welding conduit without

Fig. 1 - Mounted Welding Wire Reel

Fig. 2 - Locked

Fig. 3 - Unlocked

Loading...

Loading...