© ESAB AB 2005

- 10 -

bg17e

6.5 Replacing the swan neck

IMPORTANT! Switch off the cooling unit when replacing the swan neck or changing

the 45° swan neck position.

Point the gun's swan neck downwards to avoid water running back into the gun.

1.

a. Undo the locking nut on the welding gun and pull the swan neck straight out.

b. Fit a new swan neck and tighten the locking nut.

After replacing the swan neck, allow gas to flow through the welding gun for a few

minutes to dry up any water that may have collected in the gas ducts.

7 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

CAUTION

All guarantee undertakings from the supplier cease to apply if the customer attempts any

work to rectify any faults in the product during the guarantee period.

7.1 Daily or as necessary

Tips/nozzles

S Remove the gas nozzle.

S Clean any spatter from the gas nozzle,

intermediate tip and contact tip so that

the shielding gas can flow freely, thus

eliminating the risk of a short circuit.

S Check that the gas nozzle is free from defects. Damaged or worn tips/nozzles

should be replaced with a new one.

S Select contact tip to suit wire dimension.

S Mount the fittings.

S The gas nozzle and the front parts of the gun must be kept free of weld spatter.

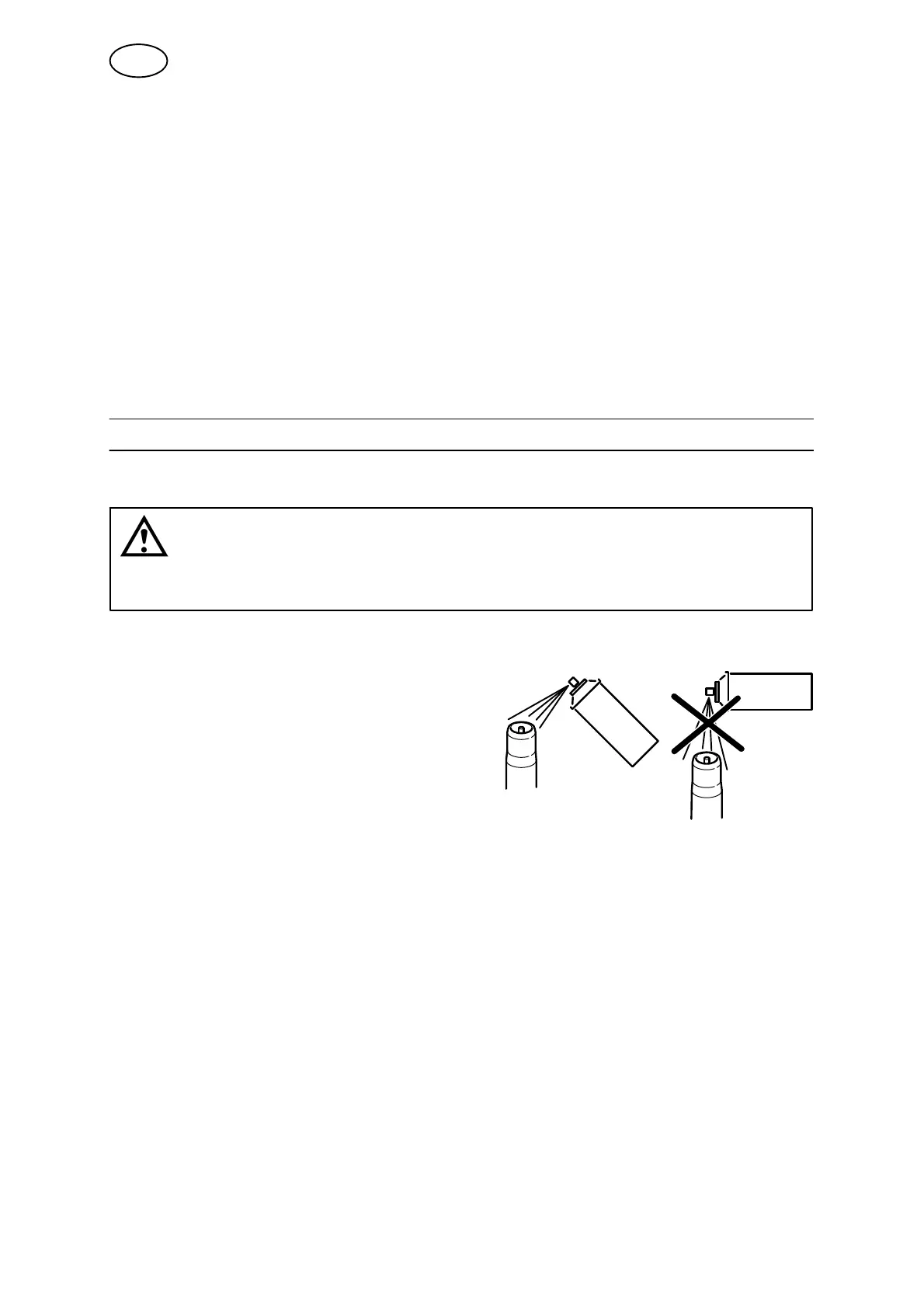

Spray anti-spatter agent at an angle into the gas nozzle from two directions. Use

ESAB anti-spatter agent to prevent spatter sticking.

Note! Never spray directly into the nozzle. Too much spray can attract dirt.

The contact tip should be replaced when the hole opening is worn to more than

double the wire diameter. Make sure that the new tip is screwed into the base.

GB

Loading...

Loading...