© ESAB AB 2005

- 12 -

bg17e

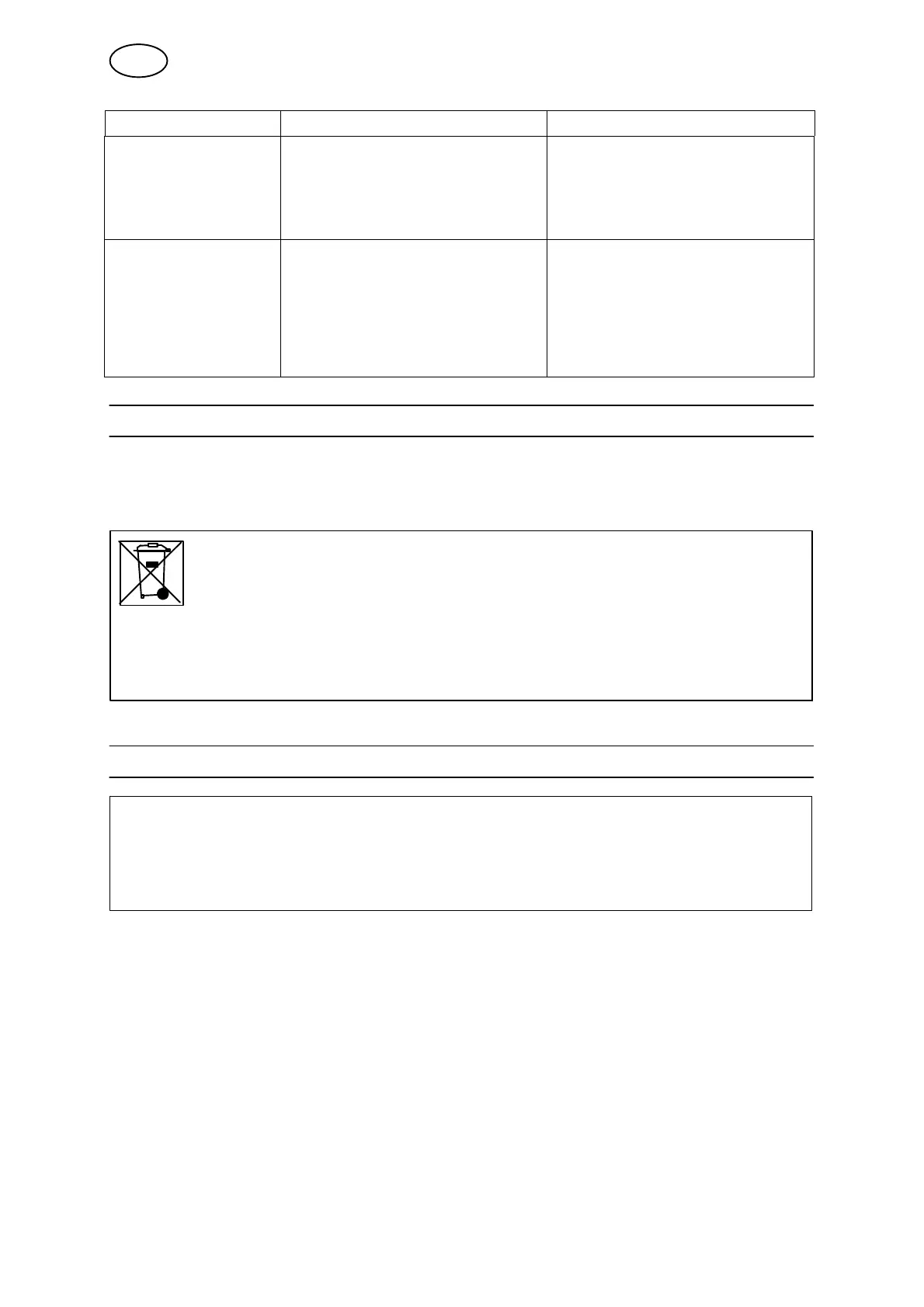

Problem SolutionCause

Variable arc S Contact tip is worn or does not

match the wire diameter.

S Incorrect welding parameters

set.

S Liner worn.

S Check/replace the contact tip

S Correct the welding parameters.

S Replace the wire liner.

Porous welds S Large amount of spatter in the

gas nozzle.

S Insufficient or total lack of

shielding gas.

S Draught is disturbing the

shielding gas.

S Clean the gas nozzle.

S Check contents of the gas

bottle/hoses and the pressure

setting.

S Shield welding area with

protective screens.

9 DISASSEMBLY AND DISPOSAL

The welding torch system is mainly made from steel, plastics and non-ferrous metal

and must be disposed of in compliance with local environmental regulations.

The disposal of coolant is also subject to local requirements.

Dispose of electronic equipment at the recycling facility!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment and its implementation in accordance with national law, electrical and/or

electronic equipment that has reached the end of its life must be disposed of at a

recycling facility.

As the person responsible for the equipment, it is your responsibility to obtain

information on approved collection stations.

For further information contact the nearest ESAB dealer.

10 ORDERING SPARE PARTS

MXH™ 300PP/400wPP is designed and tested in accordance with the international and

European standards IEC/EN 60974-7 and EN 60974-7. It is the obligation of the service

unit which has carried out the service or repair work to make sure that the product still

conforms to the said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the last page of

this publication.

GB

Loading...

Loading...