© ESAB AB 2005

- 11 -

bg17e

Cleaning the liner, swan neck and feed roller

IMPORTANT! Switch off the cooling unit when cleaning.

S Disconnect the cable assembly from the wire feed unit and lay it out straight.

S Unscrew the nut and pull out the wire liner. Remove and clean the other parts of

the swan neck.

S Blow compressed air through the wire liner from both ends in order to remove

wire shavings.

S Reinsert the liner into the cable assembly and screw the nut back on.

Point the gun's swan neck downwards to avoid water running back into the gun. In

the connector/swan neck is a wear tube. This should be blown clean regularly or

replaced once deep grooves have been worn by the wire.

Clean the feeding mechanism as required. Using compressed air requires maximum

caution to ensure no parts become damaged.

Remove the feed roller (see point 6.4) and clean the roller tracks using a wire brush.

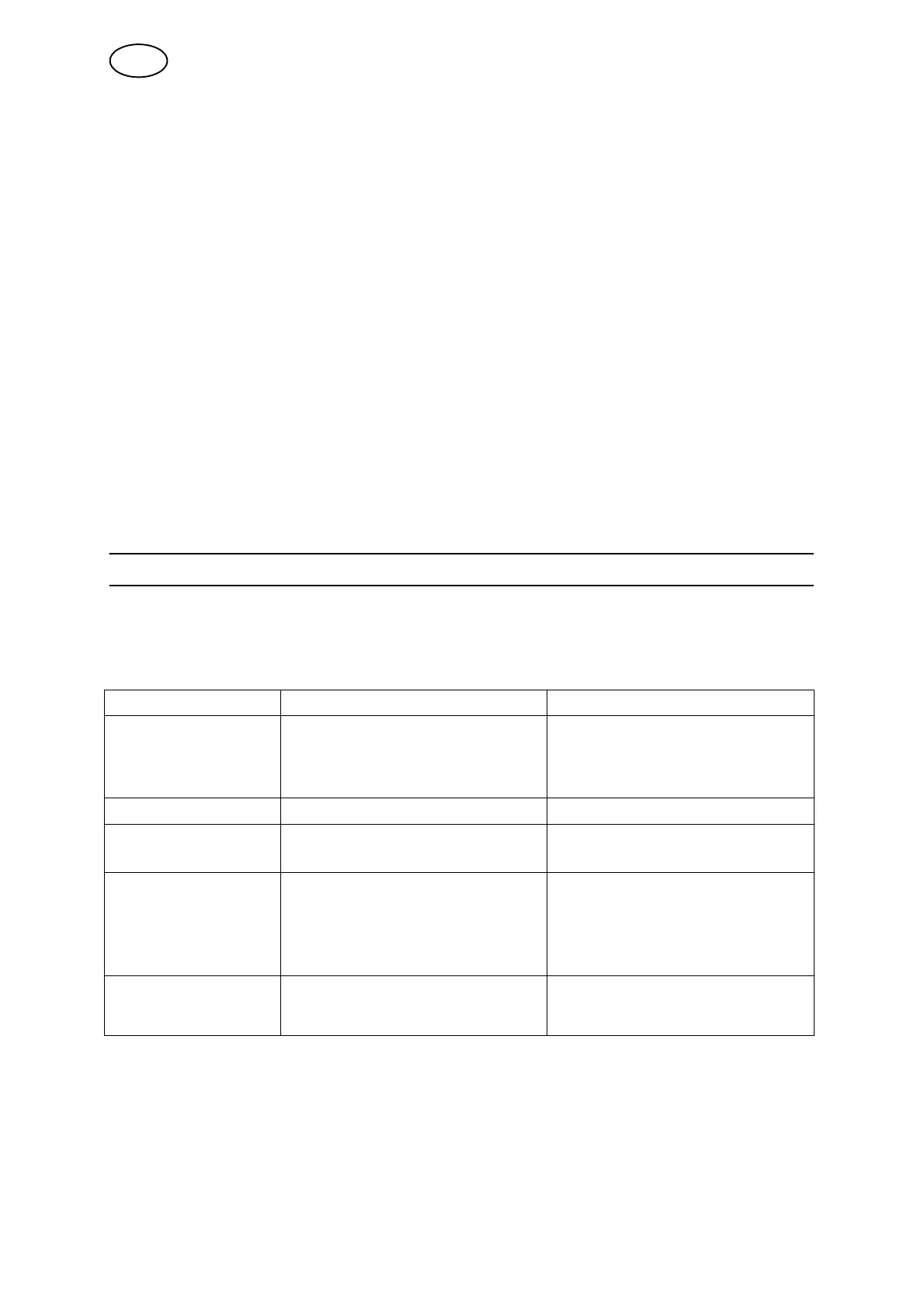

8 FAULT-TRACING

Please also read the operating instructions for the welding components, e.g. power

source and wire feed unit.

If the measures described below are not successful, please consult your dealer or

the manufacturer.

Problem Cause Solution

Welding gun becomes

too hot

S Contact tip not tight enough.

S Electrical connections to the

gun and to the workpiece are

loose.

S Check and tighten.

S Check and tighten.

No trigger function S Control cable interrupted/faulty. S Check/repair.

Wire burnt back onto

the contact tip at stop

S Wrong burn back time set.

S Worn contact tip.

S Decrease the burn back time.

S Replace.

Irregular wire feed S Liner blocked.

S Contact tip and wire diameter

do not match.

S Wrong tension set on the wire

feed unit.

S Blow through in both directions.

S Replace contact tip.

S Correct according to

manufacturer's instructions.

Short arc between the

gas nozzle and

workpiece

S Spatter bridge between the

contact tip and gas nozzle.

S Clean and spray the inside of

the gas nozzle.

GB

Loading...

Loading...