Do you have a question about the ESAB Renegade ET 300i and is the answer not in the manual?

Explains the meaning of danger, warning, and caution symbols used in the manual.

Outlines general safety rules for operating the equipment and for the workplace.

Provides a general description of the welding power sources and mentions accessories.

Lists the items supplied with the welding power source.

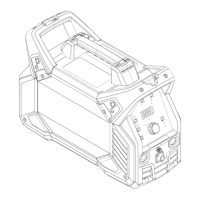

Specifies the recommended placement and clearance for the power source.

Details the correct procedure for lifting and moving the welding unit.

Covers requirements and notes regarding the electrical power connection.

Provides guidance on appropriate fuses and cable specifications for power connection.

Directs users to safety regulations and provides a note on moving the equipment.

Identifies and describes the various ports and controls on the machine.

Explains the TIG welding process and required supplementary equipment.

Explains the MMA welding process and required supplementary equipment.

Details how to connect the welding and return cables for different methods.

Describes the procedure for powering the unit on and off.

Instructions for connecting the optional cooling unit.

Explains the automatic thermal control of the cooling fan.

Describes the overheating protection mechanism and indicators.

Explains the VRD function for reducing open-circuit voltage.

Instructions on connecting and using the remote control unit.

Details the use of the USB port for retrieving welding statistics.

Details the ET 300i control panel, including navigation and weld programs.

Details the ET 300iP control panel, including navigation.

Lists and explains the parameter ranges and steps for TIG welding.

Explains TIG functions like HF start, LiftArc, and foot pedal operations.

Lists and explains MMA settings, including hidden functions and measured values.

Explains MMA functions such as Arc Force and Hot Start.

Provides a schedule for regular checks and cleaning of the equipment.

Details the procedure for cleaning the power source, including precautions.

Lists and explains common error codes and recommended actions.

| Output Current Range | 5 - 300 A |

|---|---|

| Protection Class | IP23 |

| Input Frequency | 50/60 Hz |

| Power Factor | 0.93 |

| Efficiency | 85% |

| Cooling Method | Air |

| Phase | 3 |