Do you have a question about the ESAB ET 201i DC and is the answer not in the manual?

General safety guidelines and precautions for operating welding equipment.

Guidance on navigating and understanding the manual's structure and conventions.

Information on locating and recording the unit's identification number and model.

Instructions for checking the equipment upon receipt and reporting shipping damage.

Overview of the ET 201i DC welding machine's features and capabilities.

Guidelines for safely moving the welding power source.

Explanation of the welding power source's duty cycle rating.

Technical specifications of the welding power source.

Recommended environmental conditions for operating the welding equipment.

Guidelines for selecting a suitable location to place the welder.

Details on connecting the welding power source to the electrical supply.

Guidelines for managing electromagnetic interference from the welding equipment.

General procedure for setting up the welder for operation.

Instructions for setting up the welding machine for STICK welding.

Detailed instructions for installing and using the Victor regulator.

Procedure for leak testing gas connections before operation.

Steps for setting up the welding machine for LIFT TIG welding.

Instructions for setting up the welding machine for HF TIG welding.

Steps to follow when disconnecting and storing the gas regulator.

Guidelines for properly storing the gas regulator when not in use.

General guidance on operating procedures and current settings.

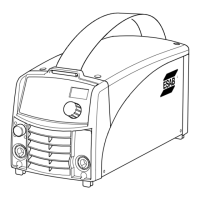

Identification and explanation of the controls and indicators on the welder's front panel.

Explanation of how to use the welding current control and its output scaling.

Correct connection of electrodes for STICK welding polarity.

Discussion on how different materials react to stick welding.

Proper connection for DC TIG welding electrode polarity.

Table providing guidance on selecting filler wire diameter based on DC current.

Recommended current ranges for different tungsten electrode diameters.

Table indicating appropriate shielding gases for various metal alloys.

Description of different tungsten electrode types and their applications.

Table of recommended parameters for TIG welding steel based on thickness.

General techniques and practices for arc welding.

Discussion of various welding positions and their applications.

Information on preparing metal joints for welding.

Techniques for beginners to practice arc welding.

Advice on positioning and posture for the welder.

Step-by-step guide on how to initiate the welding arc.

Guidance on maintaining the correct arc length for quality welds.

How to adjust travel speed for proper weld bead formation.

Techniques for creating various types of welded joints.

Discussion on the presence and study of distortion in welding.

Explanation of the factors that cause distortion during welding.

Methods for minimizing or overcoming distortion in welded parts.

Routine maintenance and inspection tasks for the power supply.

Common problems encountered during STICK welding and their solutions.

Common issues during TIG welding and recommended remedies.

Troubleshooting common problems with the welding power source.

List of key spare parts with their part numbers and reference designators.

| Input Voltage | 230 V |

|---|---|

| Input Current | 16 A |

| Output Current Range | 10 - 200 A |

| Protection Class | IP21S |

| Input Frequency | 50/60 Hz |

| Efficiency | 85% |

| Insulation Class | F |

| Type | Inverter Welding Machine |

| Duty Cycle | 60% |

| Weight | 13.7 lb |