4 OPERATION

0463 697 001

- 11 -

© ESAB AB 2021

4 OPERATION

4.1 General

General safety regulations for handling the equipment can be found in the "SAFETY"

chapter of this manual. Read it through before you start using the equipment!

Read the operating instructions for the welding components, e.g. power source and connect

accordingly.

4.2 Connections

Tighten the connections for the torch carefully to avoid overheating the connection,

connection interference, mechanical damage or leakage of liquid or gas.

Connect water connections to the torch so that the red terminal is always connected to the

corresponding red terminal and the blue terminals are always connected to the

corresponding blue terminals.

4.3 Choice of electrode

By alloying the tungsten electrode with 1% to 2% lanthanum or cerium the electron discharge

is increased, which gives better striking and restriking and therefore increased arc stability.

Alloyed tungsten electrodes have a longer service life, tolerate higher currents and are less

likely to leave tungsten residue in the weld.

Pure tungsten electrode (AC) Green WP Used for welding light metal

alloys.

Cerium alloyed tungsten electrode

(AC/DC)

Grey WC20 Used for welding light metals

such as aluminium and

magnesium. Electrode tip must

be rounded when welding.

Lanthanum alloyed tungsten

electrode (DC)

Gold WL15 Usually used for welding

stainless steel, steel, copper,

titanium etc.

Lanthanum alloyed tungsten

electrode (AC/DC)

Black WL10 Used for welding light metal

alloys, stainless steel, steel,

copper, titanium etc.

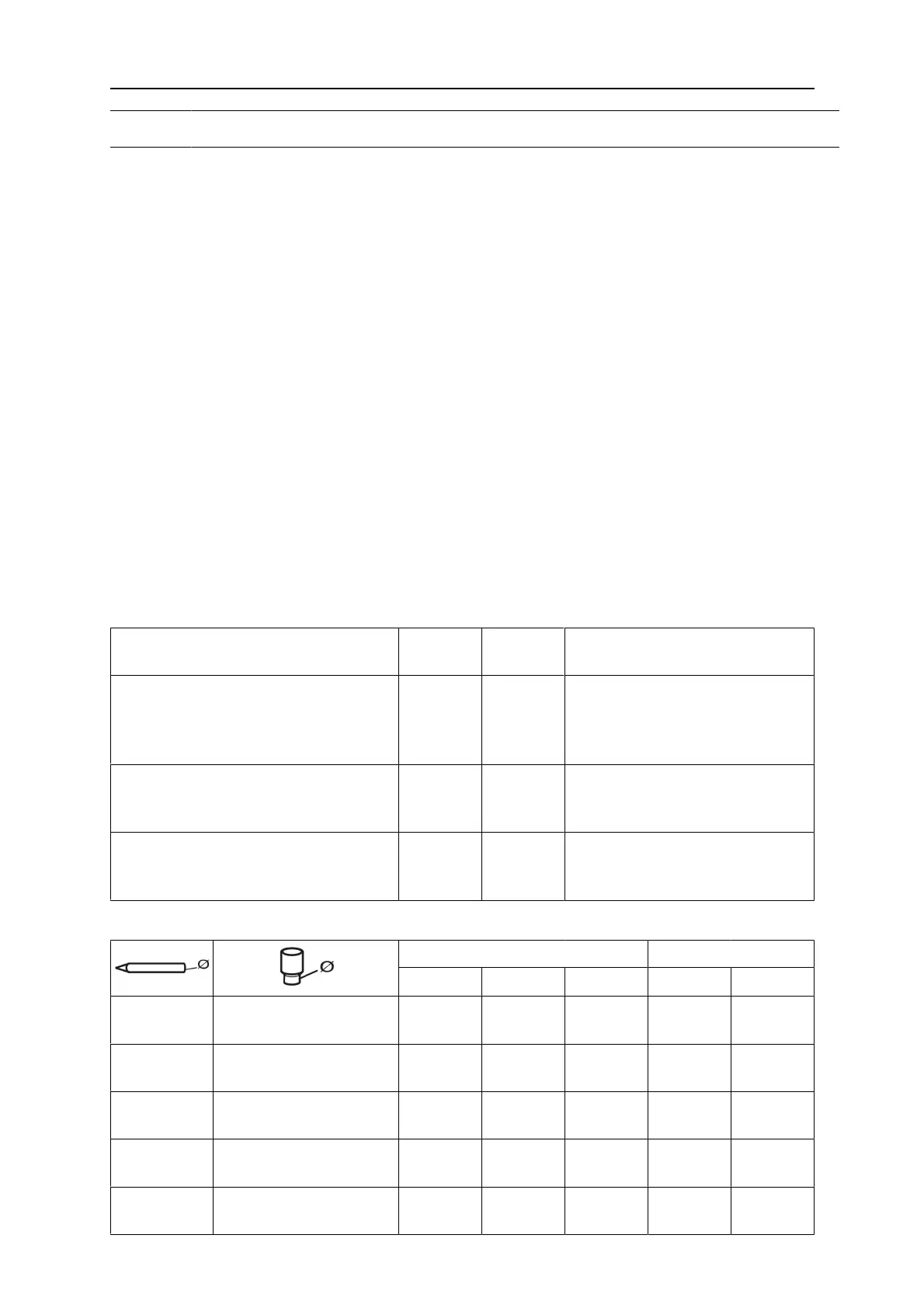

Selection table

A / AC A / DC

W CeO2 La2O3 CeO2 La2O3

1.0 mm

(0.039in.)

6.4/8.0 mm

(0.252/0.315in.)

10–60 - 15–100 70–80 20–100

1.6 mm

(0.063in.)

6.4/8.0/9.8 mm

(0.252/0.315/0.386in.)

50–100 60–90 70–160 80–140 80–160

2.4 mm

(0.094in.)

9.8/11.2/12.7 mm

(0.386/0.441/0.500in.)

100–160 90–130 110–200 150–210 120–230

3.2 mm

(0.126in.)

11.2/12.7 mm

(0.441/0.500in.)

130–180 140–190 150–205 220–320 200–305

4.0 mm

(0.157in.)

12.7 mm (0.500in.) 180–230 200–250 180–270 330–420 250–420

Loading...

Loading...