Assembly

Attach the selected attachment to the motor unit head according to Figure 13.

Use

Attachments G2 and G3 have different arrangement of knives, producing different types

of pasta. Before using the attachments G2 and G3, the pasta must be first processed

by attachment G1. Prepare and roll out the pasta dough. Powder the attachment roller

with flour. Switch on the appliance at the speed level 1. The attachment rollers will start

rotating. Let the dough repeatedly go through the rollers until smooth (you may overlap the

dough strip ends, longitudinally or transversely). Each time the dough goes through, set

the rotating knob on the attachment side to a higher value (higher number = thinner dough

strip) until you get the desired thickness (available levels are 1 to 9). The recommended

value for pasta dough is 5 to 7. Then let the dough rest to become non-sticky, and cut the

dough strips using the attachment G2 or G3 to the required width (different arrangement

of knives will produce different pasta types), and process as necessary for your purpose.

Use the speed MIN to 2.

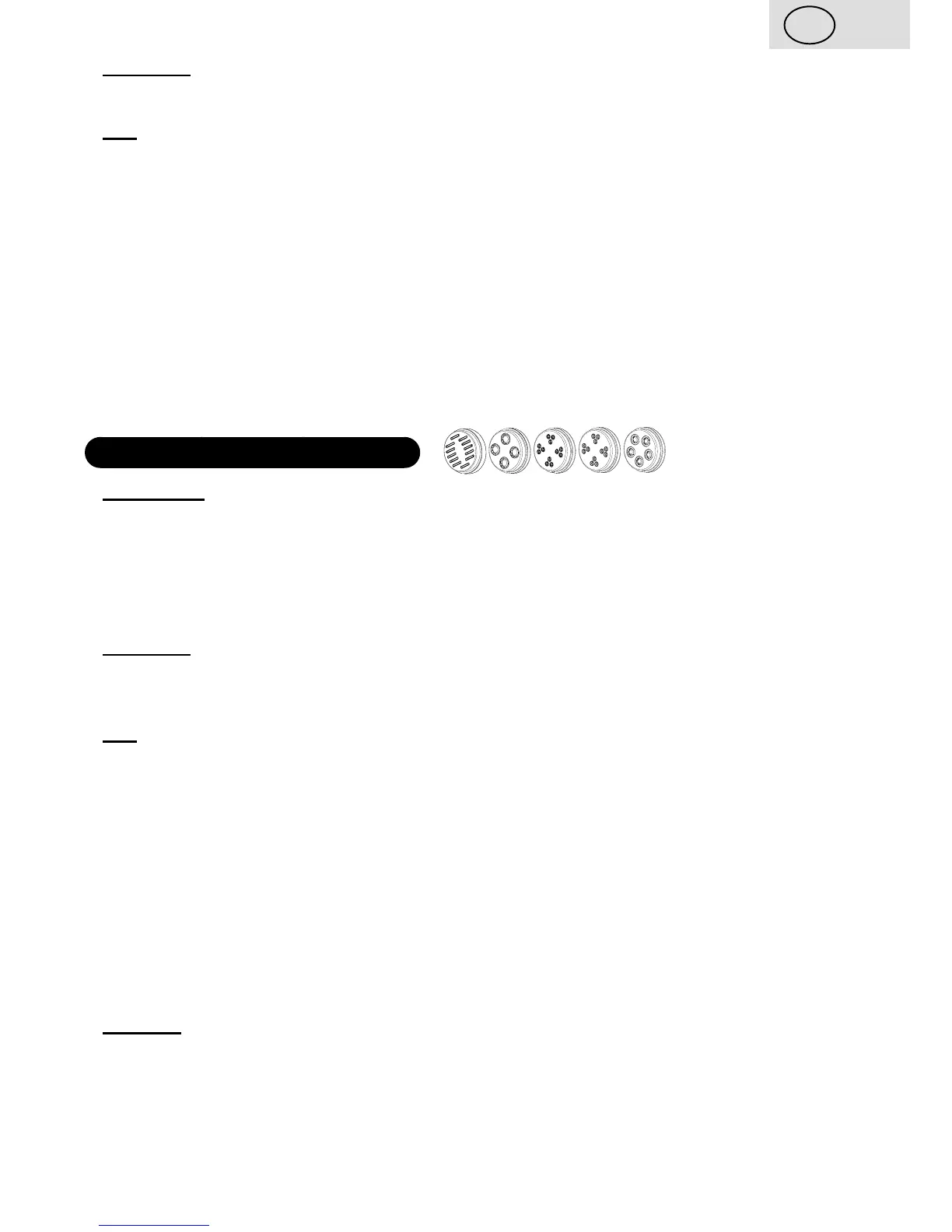

III.8) Pasta formers (I1 - I5)

Description (Fig. 6)

I1 – Pappardelle pasta former

I2 – Ditaloni Rigati, Rigatoni/Maccheroni pasta former

I3 – Stelline pasta former

I4 – Anellini, Pennette Lisce pasta former

I5 – Penne, Ditalini Rigati pasta former

Assembly

Attach the respective pasta former to the mincer and put the set on the motor unit head

according to Figures 6 and 7. Apply reverse procedure to remove it.

Use

With various exchangeable formers, you can produce various pasta types. Put the stainless

bowl B1 or a suitable tray under the mincer to catch the pasta. Make a roll from the pasta

dough, with the size equalling half of the diameter of the hopper opening. Put the roll

continuously in the hopper opening so that the screw feeder is able to take it. Cut the

produced dough by a sharp kitchen spatula or knife right on the former surface, and let if

fall into the provided container. We recommend keeping the maximum pasta length of 2 cm.

Separate the produced pasta so that it will not get stuck. After the processing, cook the pasta

within four hours or put them on a dishcloth and cover with another dishcloth. Let the pasta

dry out at the room temperature.The mincer body D0 usually gets warm during the process.

We recommend choosing the speed MIN to 2 to produce pasta. In the case of quick pasta

production (for example using the former I1), reduce the speed to the optimum level.

Cleaning

Immediately after the use, disassemble the formers into components and wash them in hot

water with detergent. Formers I2 – I5 can be dismantled into 3 separate pieces (I1 into 2

pieces). If such procedure is impossible for any reasons, let the formers soak out in water

(for example overnight) and then simply rinse under running water.

GB

86

Loading...

Loading...