10

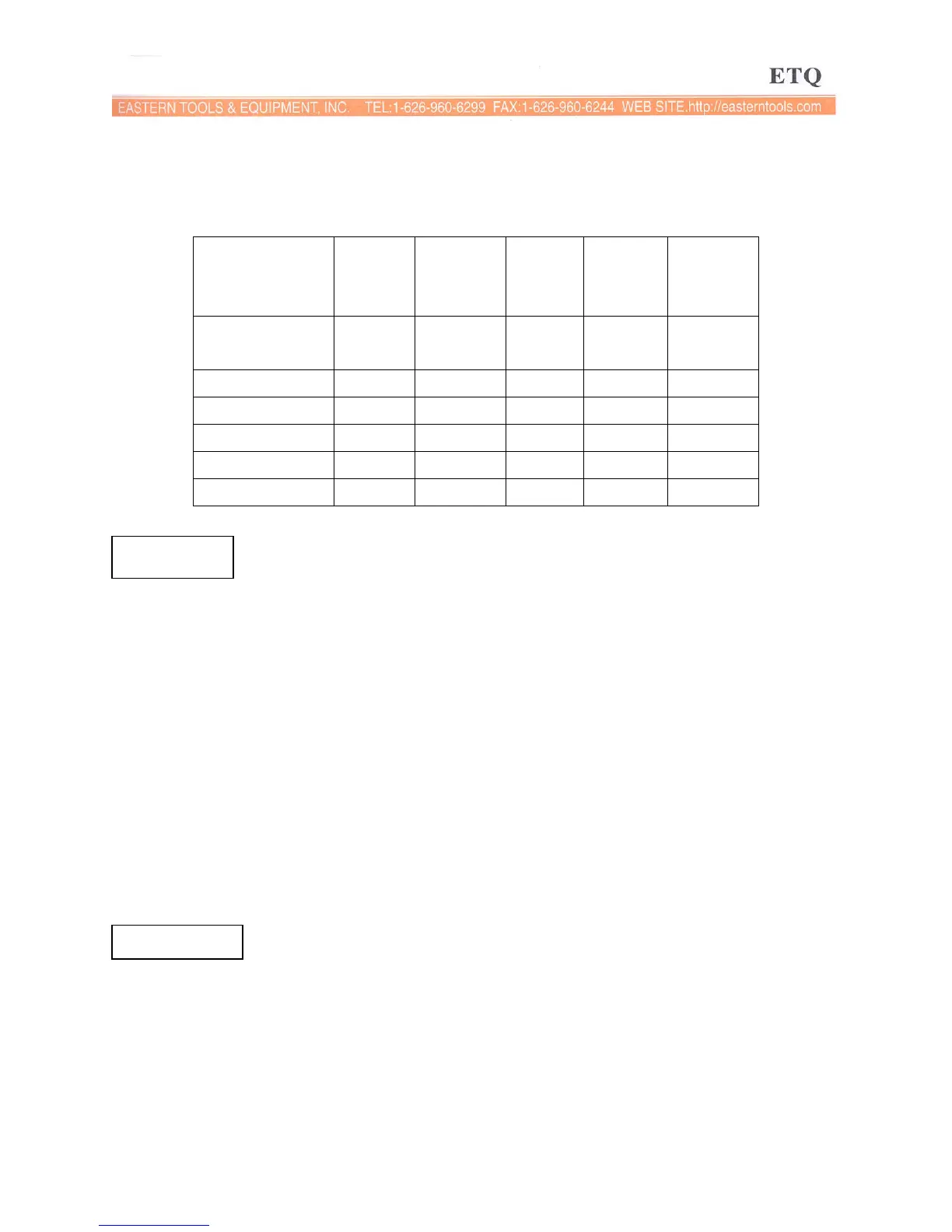

MAINTENANCE

MAINTENANCE SCHEDULE

Before

each use

Daily

after each

use

Every 8

hours

Every

40 hours

Every

100

hours

Check safety

valve

X

Drain tank X

Oil Leaks X

Check Oil X

Change Oil X

Air Filter X

CAUTION

Before performing any type of servicing, please be sure to disconnect the power source from the

compressor and drain all air from the air compressor. Failing to do so will lead to serious

injuries as compressed air and moving parts can injure you.

To ensure better operation and longer life of the air compressor, a routine maintenance schedule

should be setup and followed. The maintenance schedule above is based upon a normal working

environment and on a daily basis. If the environment conditions or operating times change to

more extreme conditions, then modifications should be made to the maintenance schedule. The

modifications made should depend on the number of hours involved in operating the compressor

as well as the environment involved. Compressors operating in extremely dirty and or hostile

environments require a more frequent maintenance schedule.

NOTES: See “Operation” section for location of controls.

CHECKING THE SAFETY VALVE

WARNING

The safety valve is a critical component in ensuring your safety. If the safety valve does not

work properly, over-pressurization may occur, causing air tank rupture or an explosion.

• Before starting the air compressor, test the safety valve by first pulling on the valve to see

that it moves freely. If the valve is stuck or does not operate smoothly, it must be

replaced with the same type of valve.

Loading...

Loading...