14

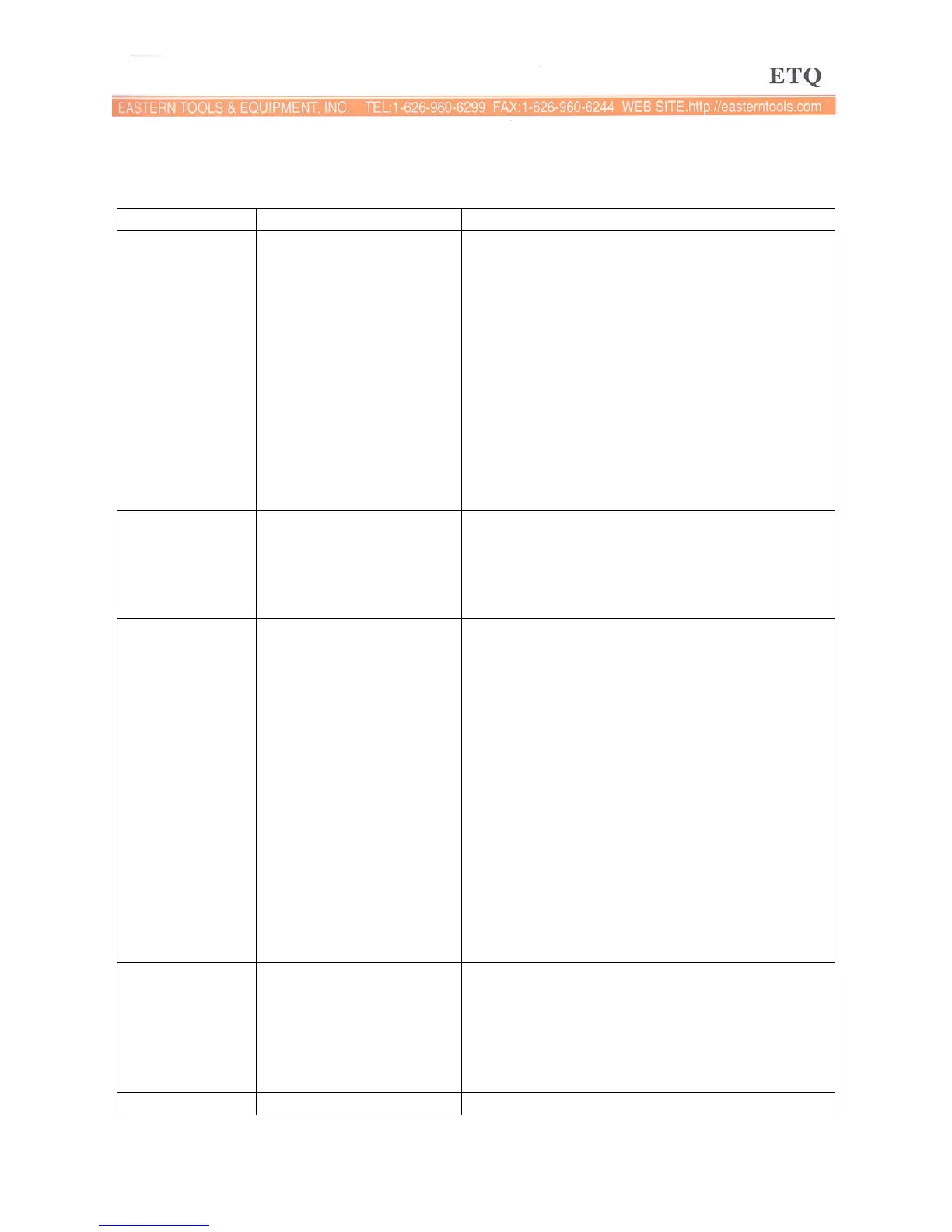

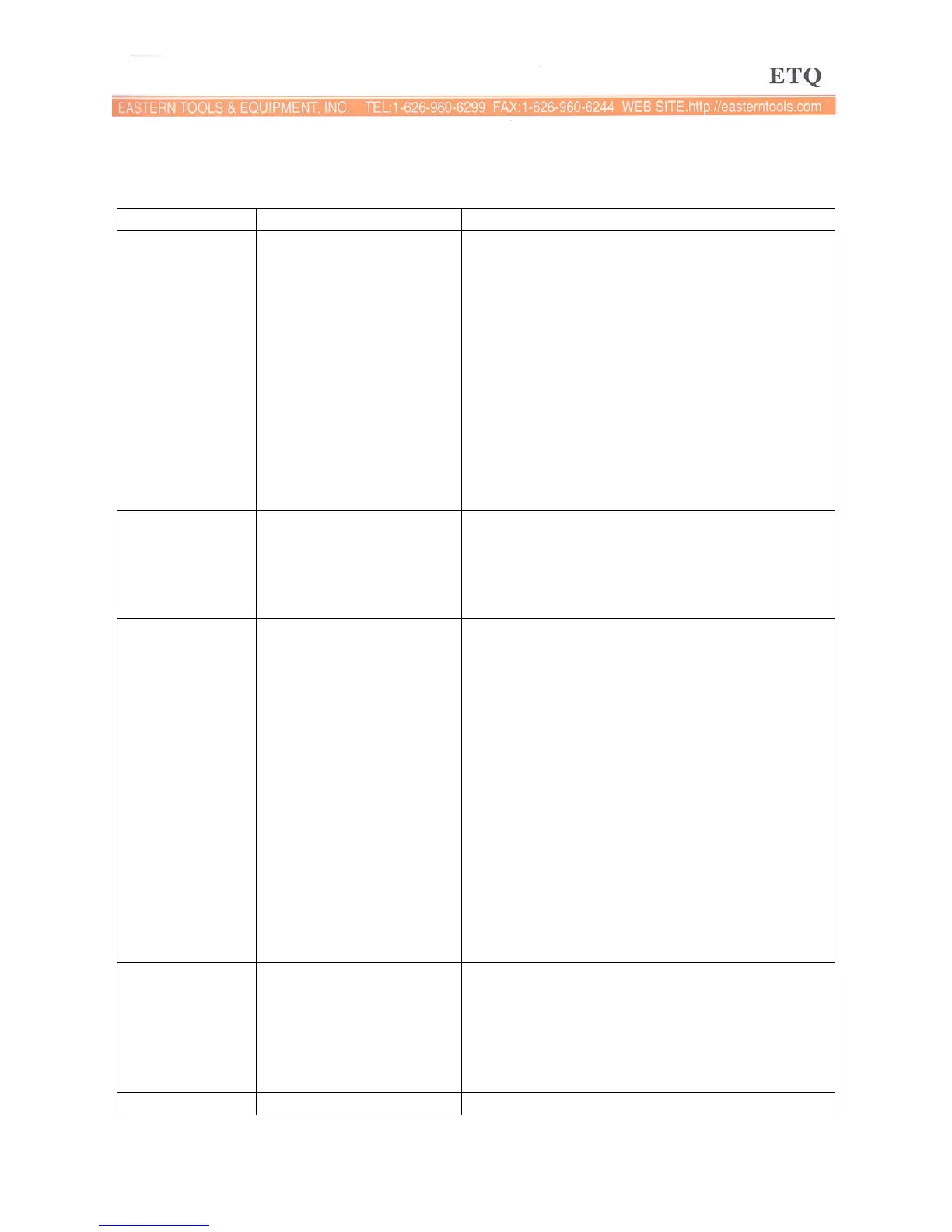

TROUBLESHOOTING

Symptom Probable cause Corrective Action

Low discharge

pressure.

1. Air demand exceeds

pump capacity.

2. Leaking air

3. Restricted air intake

4. Blown gaskets

5. Leaking or damaged

valves.

1. Decrease air demand or use a larger

capacity air compressor

2. Listen for high pitched escaping air. Apply

soap solution to all fittings and

connections. Bubbles will appear at points

of leakage. Tighten or replace leaking

fittings or connections.

3. Clean air filter element

4. Replace faulty gaskets.

5. Remove head and inspect for valve

breakage, misaligned valves, damaged

valve seats, etc. Replace defective parts

and reassemble.

Pump

overheating and

damaging air

filter.

1. Insulating gasket

between filter and

head is missing.

2. Broken valves blown

gasket.

1. Install gasket.

2. Replace valves or install new gasket.

Excessive noise

or abnormal

noise

1. Loose motor.

2. Low oil in crankcase

3. Worn connecting

rods

4. Worn piston pin

5. Piston hitting valve

plate.

6. Noisy check valve.

1. Tighten motor bolts.

2. Refill oil to the proper level. Also, if

always low, check for possible damage to

bearings or oil leaks

3. Replace connecting rod. Maintain oil level

and change oil more frequently.

4. Remove old piston pin, measure and verify

specifications are within limits. If not,

replace piston pin and replace oil more

frequently.

5. Remove the compressor head and valve

plate for carbon deposits or other foreign

objects. Replace the head and valve plate

and use a new gasket.

6. Replace.

Large quantities

of oil in air

supply

1. Worn piston rings.

2. Air intake clogged

3. Oil level in

compressor head to

high.

4. Wrong oil viscosity

1. Replace with new rings.

2. Clean air filter

3. Drain some of the oil.

4. Use SAE30

Water in 1. Water increases with 1. Drain tank daily.

Loading...

Loading...