(1) With 50/50 Ethylene Glycol/water coolant mix.

(2) Service Bulletin SB/EUR/006 Issue 1 is complied with.

WARNING

The Rotax 912 UL has not been certified as an aircraft engine and its failure may occur at

any time. The pilot is fully responsible for consequences of such a failure. Never fly over

Note 1: propeller pitch to be set to achieve 4600rpm static at full throttle.

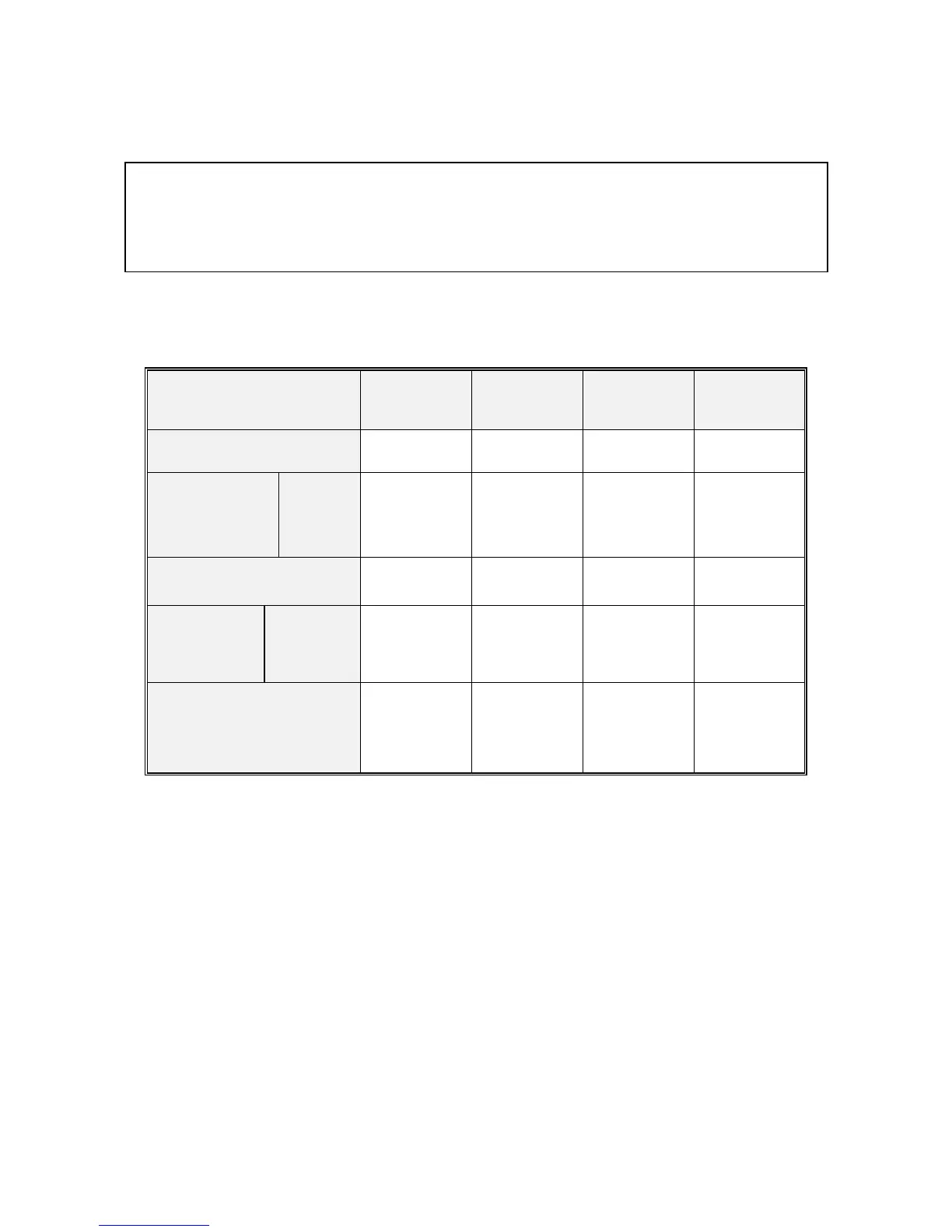

2.18 Engine Operational Limits

140 °C

284 °F

Oil

Pressure

0.8 bar

12 psi

2 - 5 bar

29 – 73 psi

0.8 - 2 bar

12 - 29 psi

5 – 7 bar

73 – 102 psi

7.0 bar

102 psi

cold engine

starting

2.19 Engine Mount

The engine mount is welded from chrome-molybdenum tube and is attached to the firewall by 4

bolts. The assembly incorporates 4 anti-vibration mounts (Silent blocs).

2.20 Engine Cowlings

Two composite cowlings, upper and lower, cover the power plant. Both cowlings are coated

internally with fireproof paint. The upper cowling is connected to the lower cowling by quarter turn

fasteners and is easily removed for pre-flight inspections. Removal of the lower cowling requires

removal of the screws supporting the radiator to the front of the cowling, then removal of the

screws supporting the lower cowling’s rear edge.

Engine cowlings disassembly and assembly

• The upper cowling: The disassembly and assembly are both easy by releasing

the quick-closing locks (or screws). The upper cowling is usually removed during

Loading...

Loading...