EV-97 Eurostar SL Microlight Maintenance Manual GEN/EUR/04 Issue 4 20

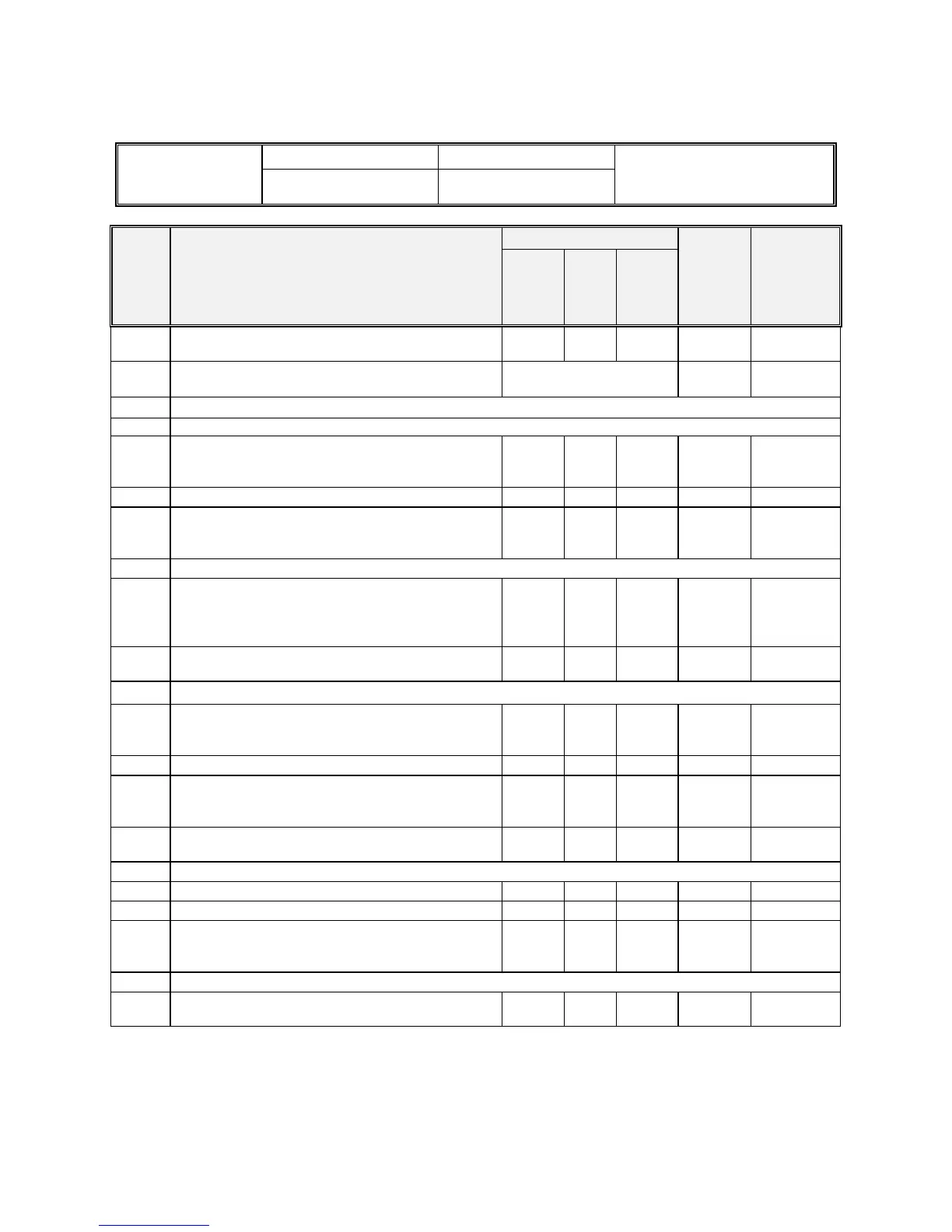

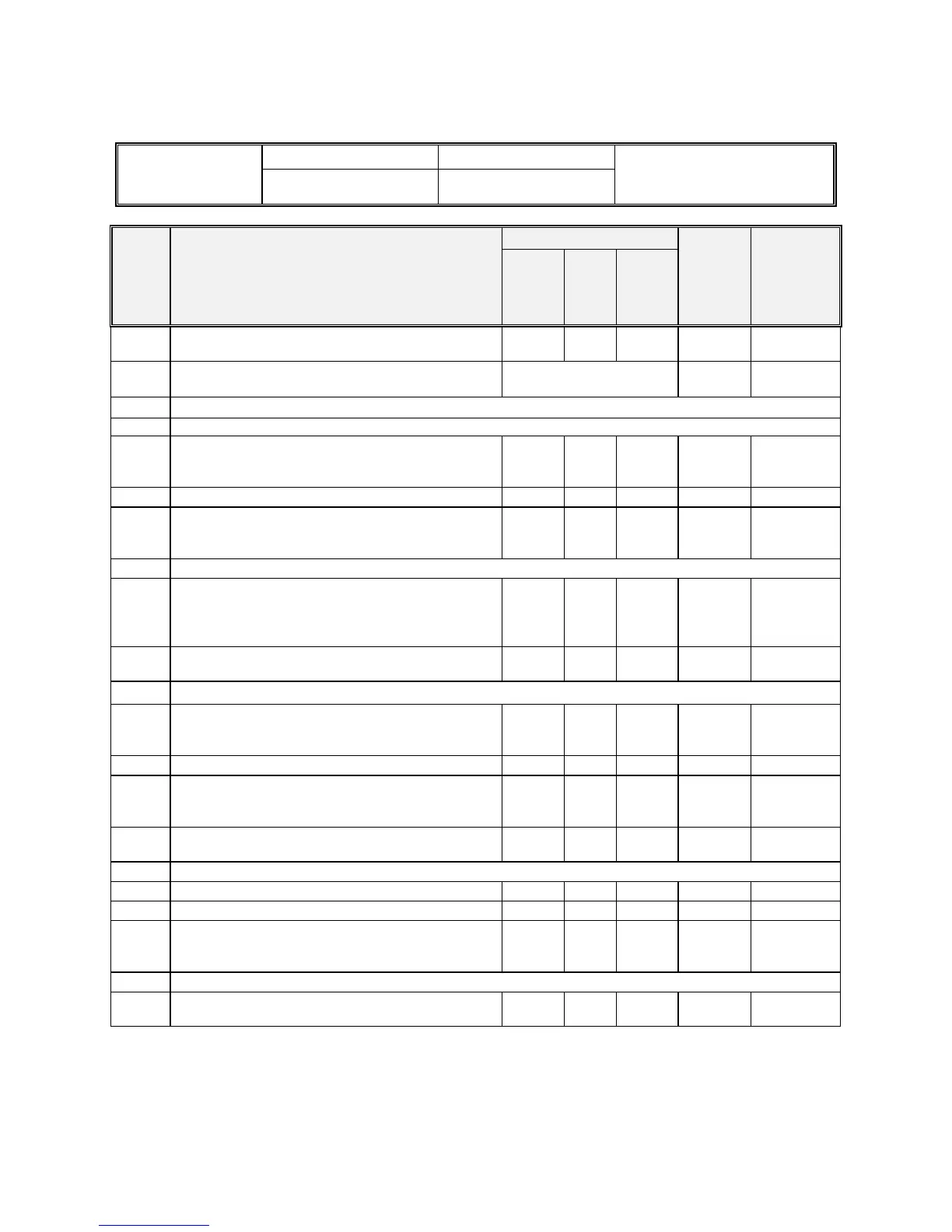

4.3.3 Periodic Maintenance and Inspections.

S/N: Hours flown:

Date of inspection

:

EV-97 EUROSTAR

SL MICROLIGHT

Registration: No. of takeoffs: Inspection period: hrs.

Event Event description

Carried

out by:

Inspected

by:

after the first

25 hrs.

every

50

hrs.

Prior to the inspection clean and wash the aircraft

surfaces, if needed.

ENGINE

see engine manufacturer´s

Fiberglass engine cowlings

Check condition of cowlings and Camlock

Visually check inside fireproof primer paint

- White color T 50, Norm V1000 N 56582

Visually check condition, attachment, security of

attachment bolts: engine to mount, mount to

firewall. Carefully

check engine mount for

cracks, abrasion and other damage.

Visually check condition of rubber silentblocks -

replace those cracked or excessively deformed

Visually check condition, attachment and security

of air filters on each carburettor inlet.

- clean and oil filter as necesary.

Visually check condition of carb. rubber adaptors.

Check carburettor - condition, control cables

attachment, lubricate cables at inlet to the

Bowdens‘ conduits.

Check coolant carb heat system for security and

leaks

Visually check attachment and security

Check charging – charge if needed; see note 1

Visually check condition and attachment of

Visually check condition and integrity of wires,

connections, security of wires

Note 1: The Li-ion battery must only be charged with its dedicated, (constant current) charger. The

use of a normal lead-acid battery charger (constant voltage) may result in damage to the battery

and a reduction in its life.

Loading...

Loading...