WIRING

POWER CONNECTION

Power the EVO/ECM-Modbus RTU with a ~24V 50/60 Hz 10 VA low voltage

power source. Connect the hot side of the power source to the ~24V

connection. Connect the neutral side of the power source to the neutral

connection. Observe all building and electrical code requirements

concerning low voltage power sources and wiring to insure a safe, reliable

installation. In most jurisdictions the neutral must be earthed.

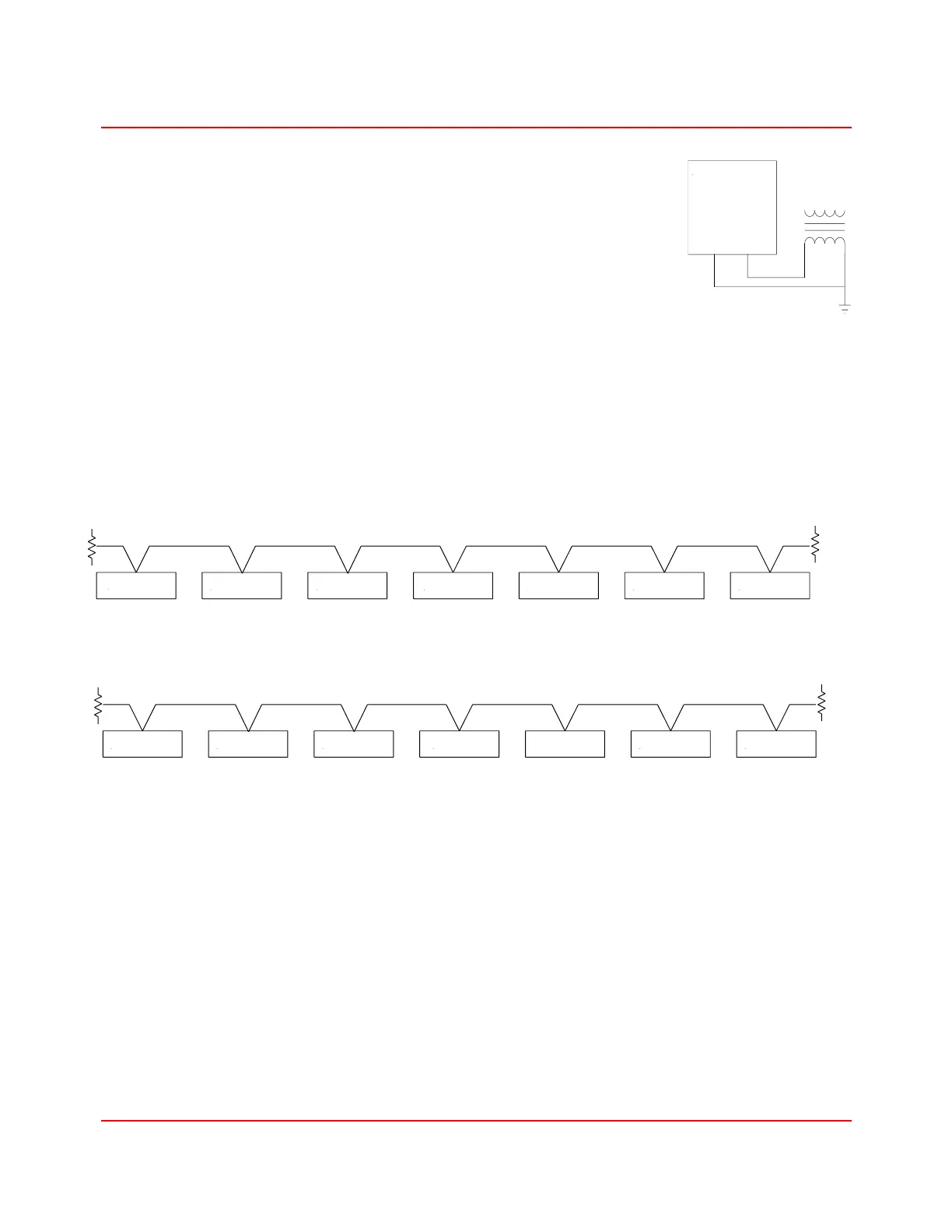

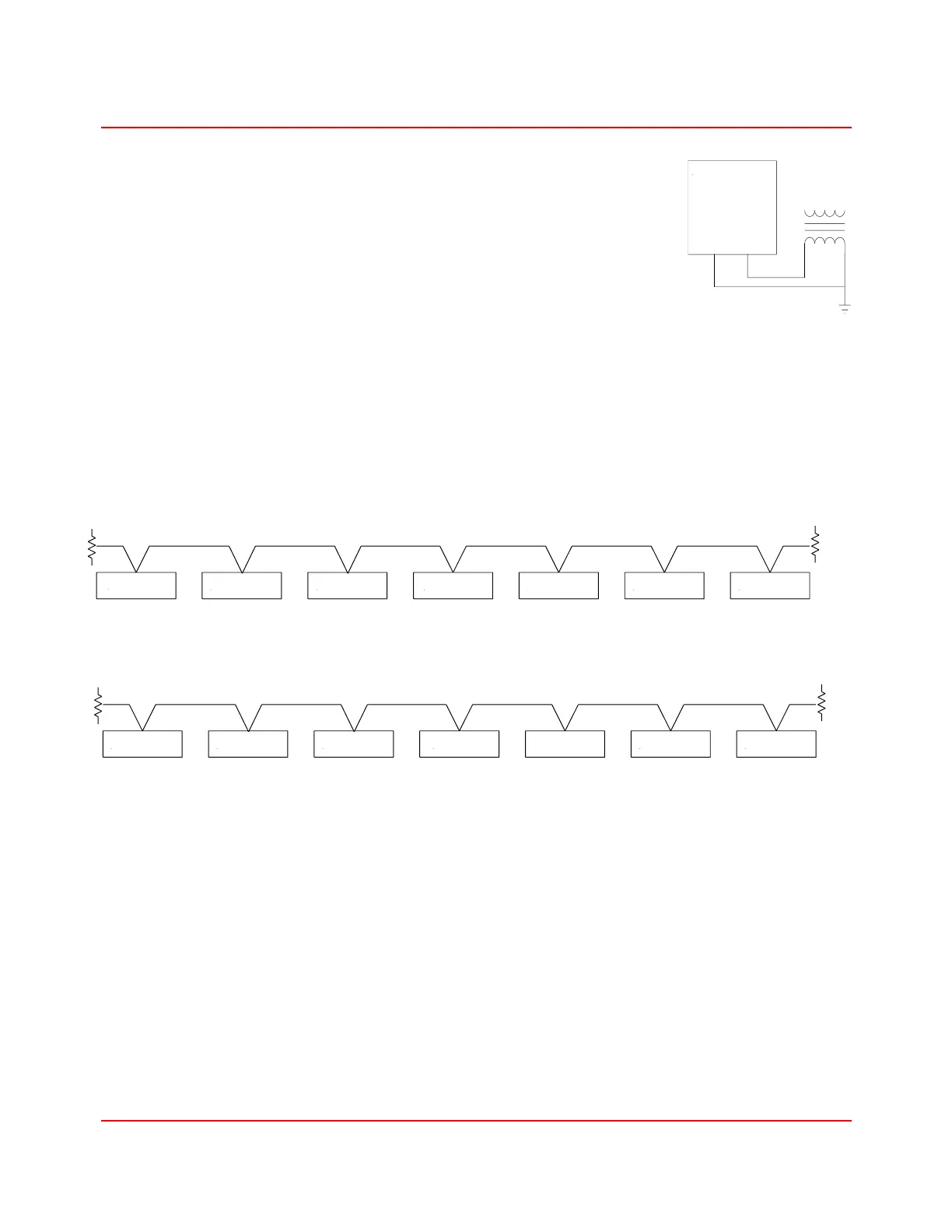

TRUNK CONNECTION

A single trunk routes from one EVO/ECM-Modbus RTU to the next, connecting up to 31 RTUs to

the Modbus RTU master. The trunk may be up to 4000 feet long. Connect a 120-ohm 1/4-Watt

terminating resister at each end of the trunk. The most common connection places the Modbus

RTU master at one end of the trunk. Many Modbus RTU masters have a non-removeable built in

terminator or use an impedance altering means to provide line bias. These masters must be

placed at the end of the line.

When possible, placing the Modbus RTU master in the center of the trunk improves application

versatility, often reduces installation costs, and improves communications reliability.

The trunk cable field terminates to a plug-in connector at each RTU. Use a twisted pair cable with

an overall foil shield. Recommend the use of EIA RS-485 cable 22-24 AWG twisted and balanced,

with an impedance of 100-130 ohms, a capacitance below 100 pF per meter (30 pF per foot), with

a braided shield. Connect the shield to the Shield/Common terminal at each RTU as shown in the

picture below. Do not ground the shield at the RTUs. The shield must be chassis grounded at the

master only.

The shield wire is usually not insulated. Keep the shield leads short between the cable sheath and

the shield connection. Let the other wires be longer!

Loading...

Loading...