www.evolutionfury.com

17

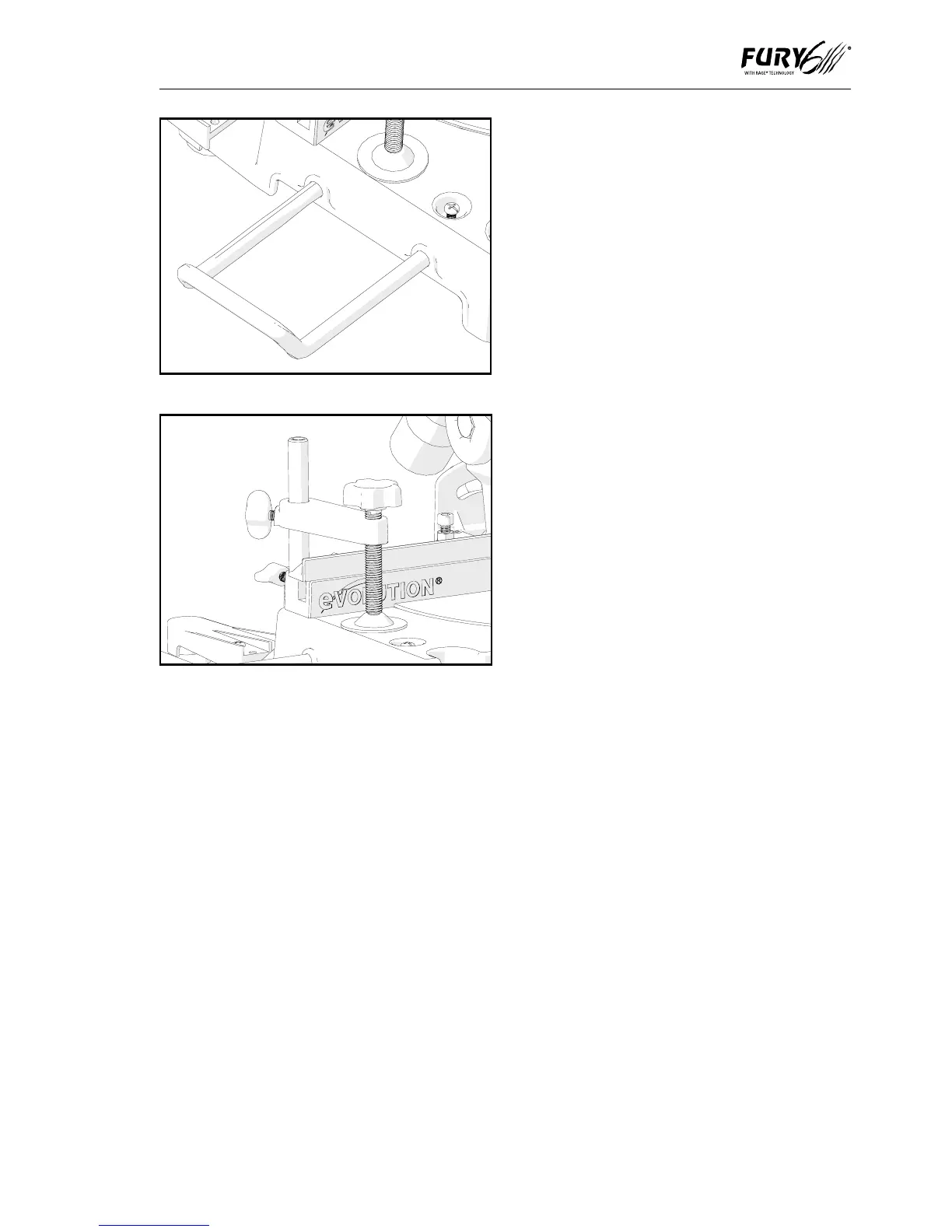

WORKPIECE SUPPORTS (Fig. 8)

Workpiece supports can be fitted to both

sides of the machine base if required.

• LoosentherelevantWorkpieceRetaining

Screw located in a socket at the top front

of the machine base.

• InserttheWorkpieceSupportintothe

holes machined in the base.

NOTE: The Workpiece Support should be

pushed ‘fully home’ into the machine base.

Correct installation will require approximately

65mm of the Workpiece Support to slide into

the machine base.

• FastentheWorkpieceSupportintothe

base by tightening the Retaining Screw.

Workpiece Supports can be very useful in

providing extra support for long workpieces

when using the Fury6 in Mitre Saw

configuration.

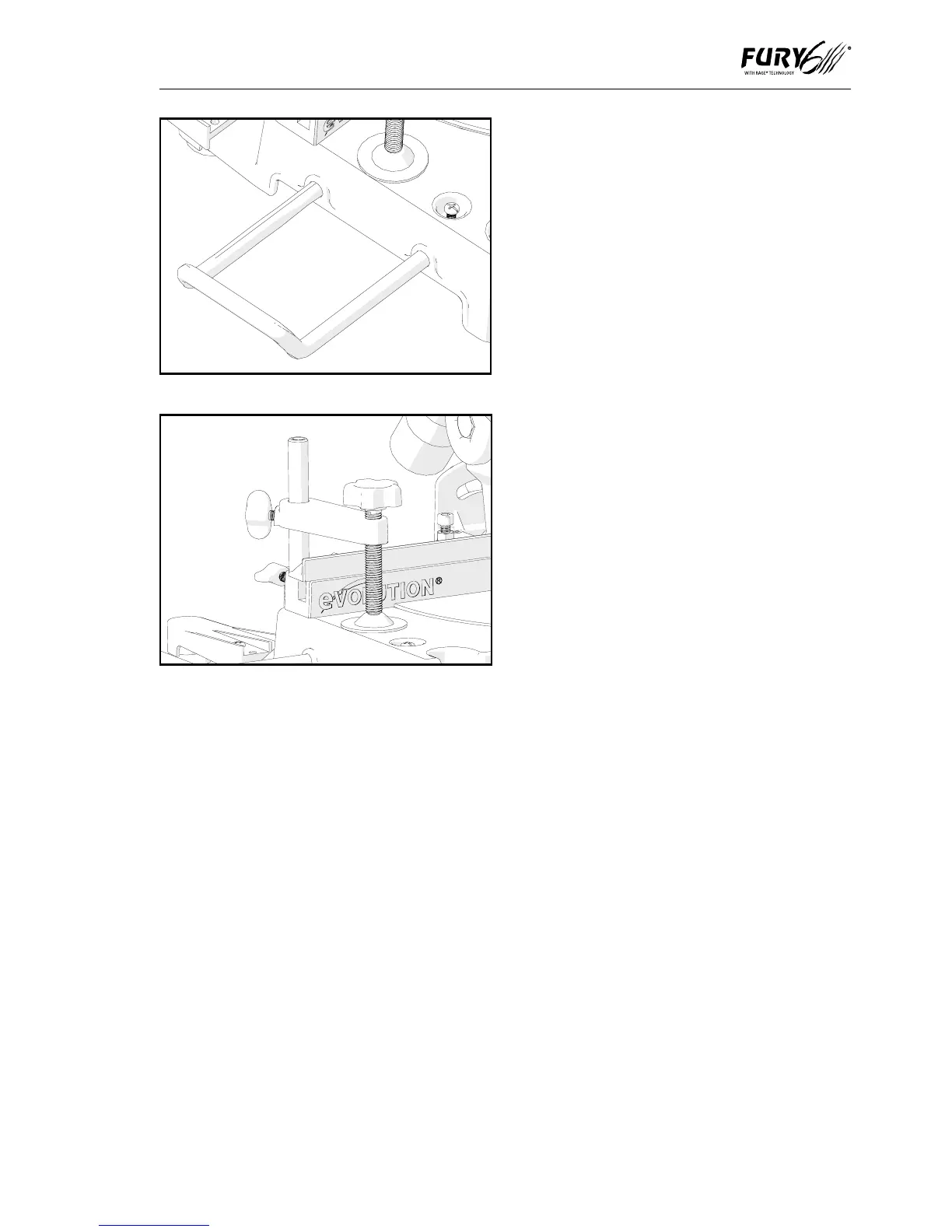

HOLD DOWN CLAMP (Fig. 9)

A Hold Down clamp is supplied with the Fury6.

Two sockets (one on either side) are

incorporated into the rear of the machines

fence.

• Fitthepillaroftheclampintothesocket

that best suits the cutting application,

ensuring that it is pushed fully down.

• Tightenthefencethumbscrewtolockthe

pillar of the Hold Down Clamp into the

fence socket.

• Puttheworkpieceontotherotarytable

and against the fence.

•AdjusttheHoldDownClampsothat

it securely holds the workpiece to the

rotary table.

• Beforeattemptinganycuttingcheckto

ensure that the clamp does not interfere

with the blade path as the Cutting Head

is lowered.

OPERATING INSTRUCTIONS

MITRE SAW CONFIGURATION

WARNING: It is important that the operator

is adequately trained in the use, adjustment

and operation of the machine, and has read

the Instruction Manual before commencing

operations.

NOTE: We recommend that when the

Fury6 is being used as a Mitre Saw, the

complete Fence Assembly is removed from

the machine as stored safely for future use.

1. Releasing the Cutting Head

NOTE: When configured in Mitre Saw

mode the Cutting Head will be automatically

locked in its upper position with the

Retractable Lower Blade Guard completely

covering the blade teeth.

Fig. 9

Fig. 8

Loading...

Loading...