20

www.evolutionpowertools.com

GENERAL OPERATING ADVICE

• Ensurethatbystandersarekeptatasafedistance

from compacting operations. If necessary cordon

off the work area and post WARNING notices.

• Planyourwork,andthepathyouintendthemachine

to travel, before you start compacting operations.

• Surveytheworkingareabeforeyoubeginand

remove or otherwise neutralise any obstructions/

obstacles that could pose a danger.

• EnsureyouhaveallthecorrectPPEandknowhow

to use it.

• Thecompactorwilltravelforwardsunderitsown

power. Gentle inputs from the operator on the

machines handle are all that is necessary to ‘steer’

the machine. The operator should hold the anti-

vibration handle grip with both hands, and the hands

should be positioned as far apart as possible.

• Severalpassesovertheworkareamayberequired

to compact the material to the desired density.

• Iftheworkareaissloped,workupanddownthe

sloping surface, not across

MAINTENANCE

HULK PETROL

Regular maintenance is essential to keep your

machine and its accessories in serviceable condition.

We recommend that only competent operators who

have experience in servicing and maintaining petrol

engines attempt these procedures. If in doubt have

the machine serviced at an Evolution approved

Service Centre.

1. Engine oil replacement

Engine oil should be replaced after the initial

‘running in’ period and at the intervals specified

in the Service Schedule.

Note: Engine oil is easier to replace when the engine

has been run up to temperature and the oil is warm.

• Ensurethattheengineispositionedonahardlevel

surface.

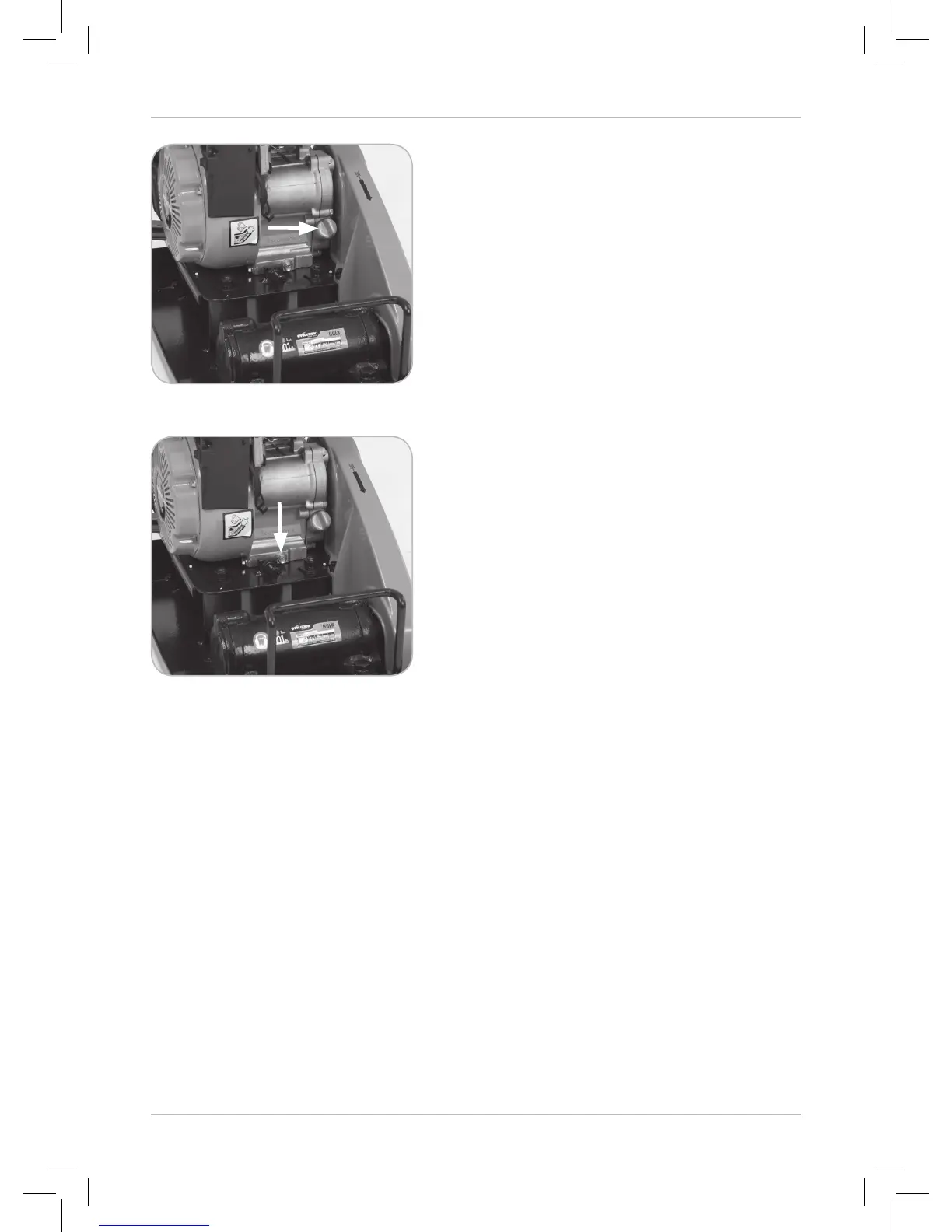

• Removetheoilllercap.(Fig. 11)

• Placeasuitableoilcollectionpanundertheengine.

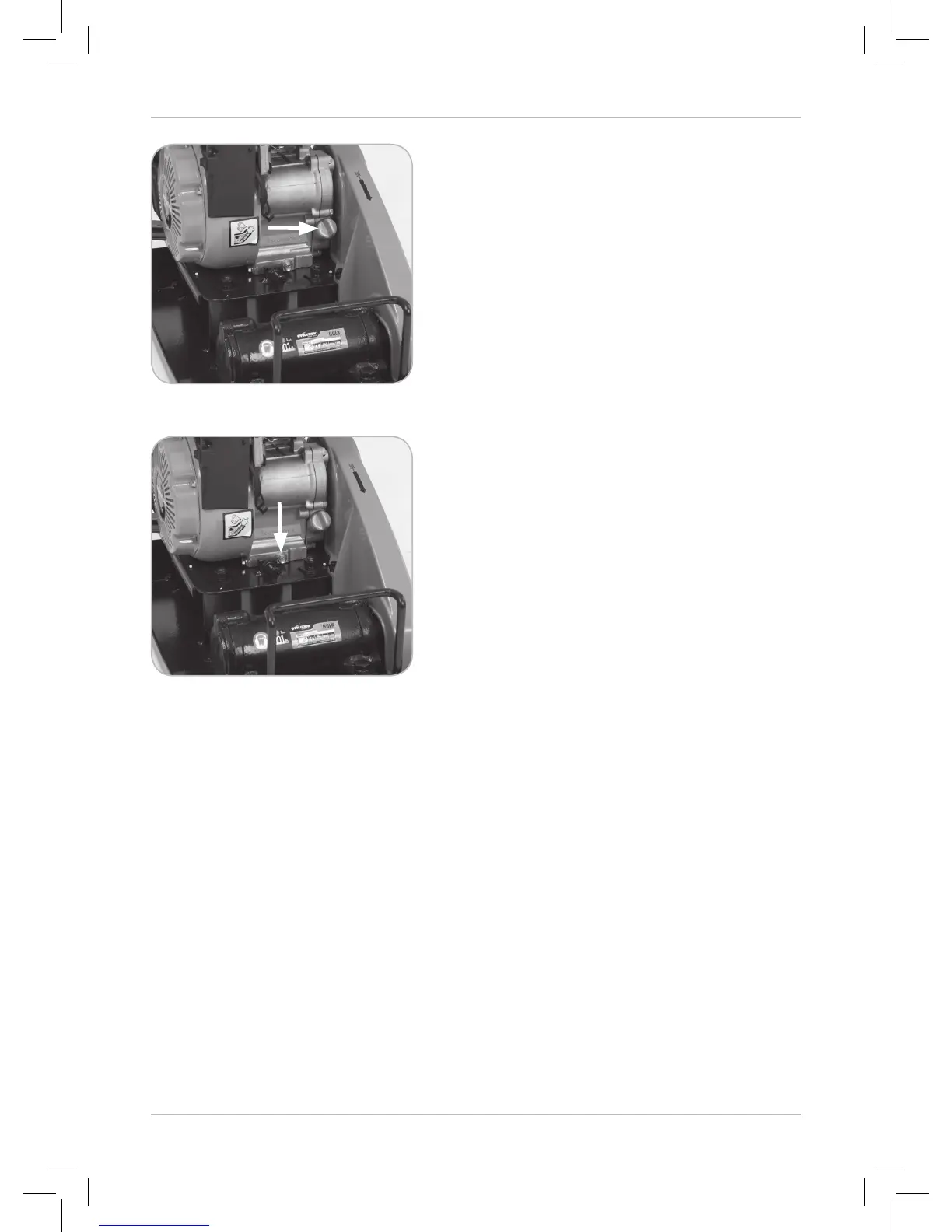

• Removetheoildrainplugsothattheoilcandrain

completely from the engine. (Fig. 12)

Fig. 11

Fig. 12

Loading...

Loading...