24

www.evolutionpowertools.com

WARNING: Do not adjust the adjustment/tentioning bolt without loosening the four mounting

bolts, as this could cause damage to the engine casing.

Note: Care must be taken to ensure that the engine remains ‘square’ and ‘inline’ on the mounting

plate. If the engine were to be in a slightly ‘twisted’ configuration on the mounting plate, the drive belt

and pulleys would be put under ‘distress’ and wear quickly ensue.

• ReplacethedriveBeltGuardandsecurelytightenthethree(3)socketheadedscrewsintheir

original positions.

6. Recoil Starting System

The ventilation slots should be kept clean and free from any obstructions.

Remove any foreign matter from the ventilation slots.

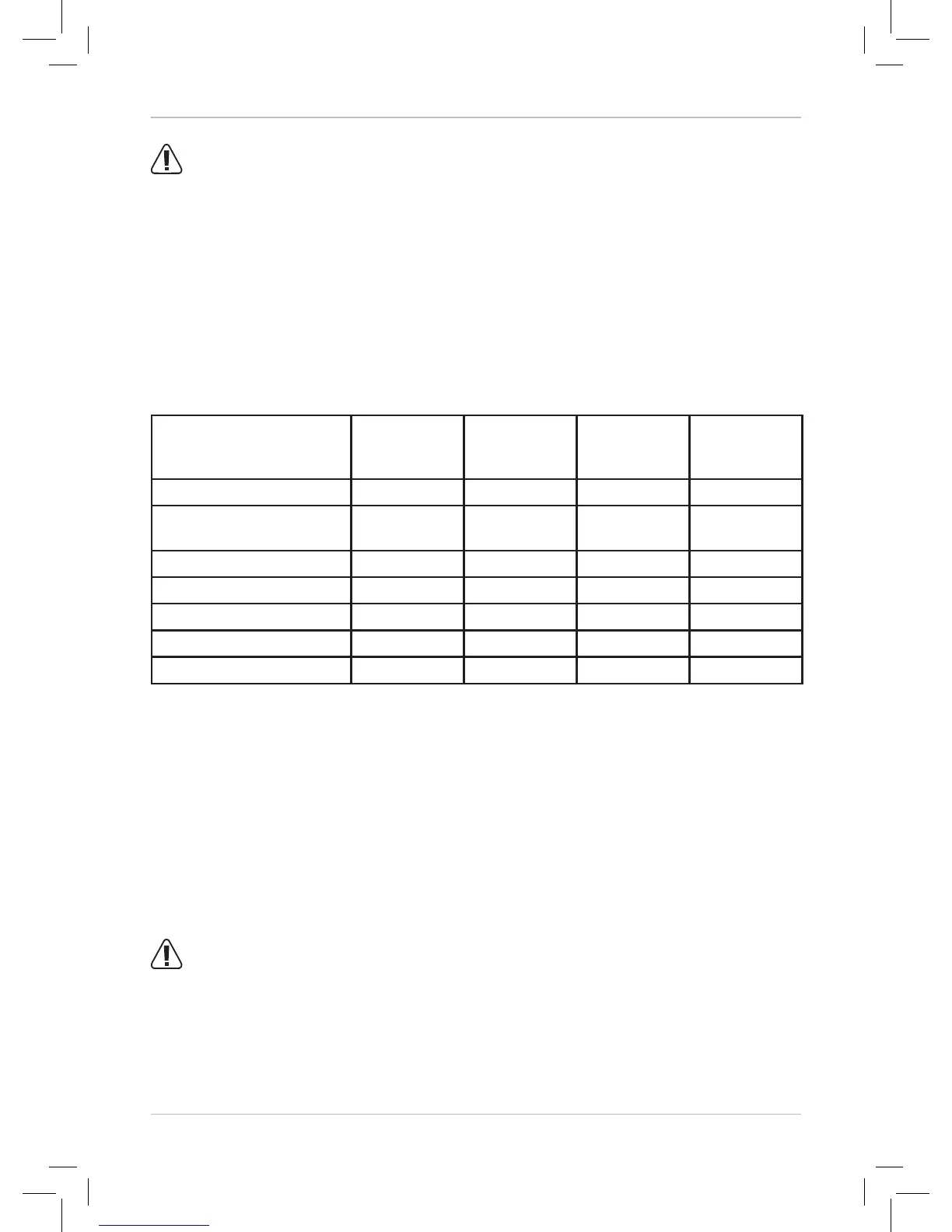

HULK PETROL

ROUTINE MAINTENANCE

SCHEDULE

After first 4

hours

Every

20 hours or

monthly

Every

50 hours or

3 monthly

Every

100 hours or

6 monthly

Engine Oil Level Check

● ●

Engine Oil Change

●

(1

st

change only)

●

Air Filter Check

●

Air Filter Replace

●

Spark Plug Check

●

Drive Belt Tension

● ●

Fuel Filter Check/Clean

●

MAINTENANCE HULK ELECTRO

Note: Any maintenance must be carried out with the machine switched off and disconnected

from the power supply.

Check that all safety features and guards are operating correctly on a regular basis. Only use this

machine if all guards/safety features are fully operational.

All motor bearings in this machine are lubricated for life. No further lubrication is required.

Use a clean, slightly damp cloth to clean the plastic parts of the machine. Do not use solvents or

similar products which could damage the plastic parts.

WARNING: Do not attempt to clean by inserting pointed objects through openings in the

machines casings etc. The machines air vents should be cleaned using compressed dry air.

Loading...

Loading...