26

www.evolutionpowertools.com

GENERAL TROUBLESHOOTING GUIDE

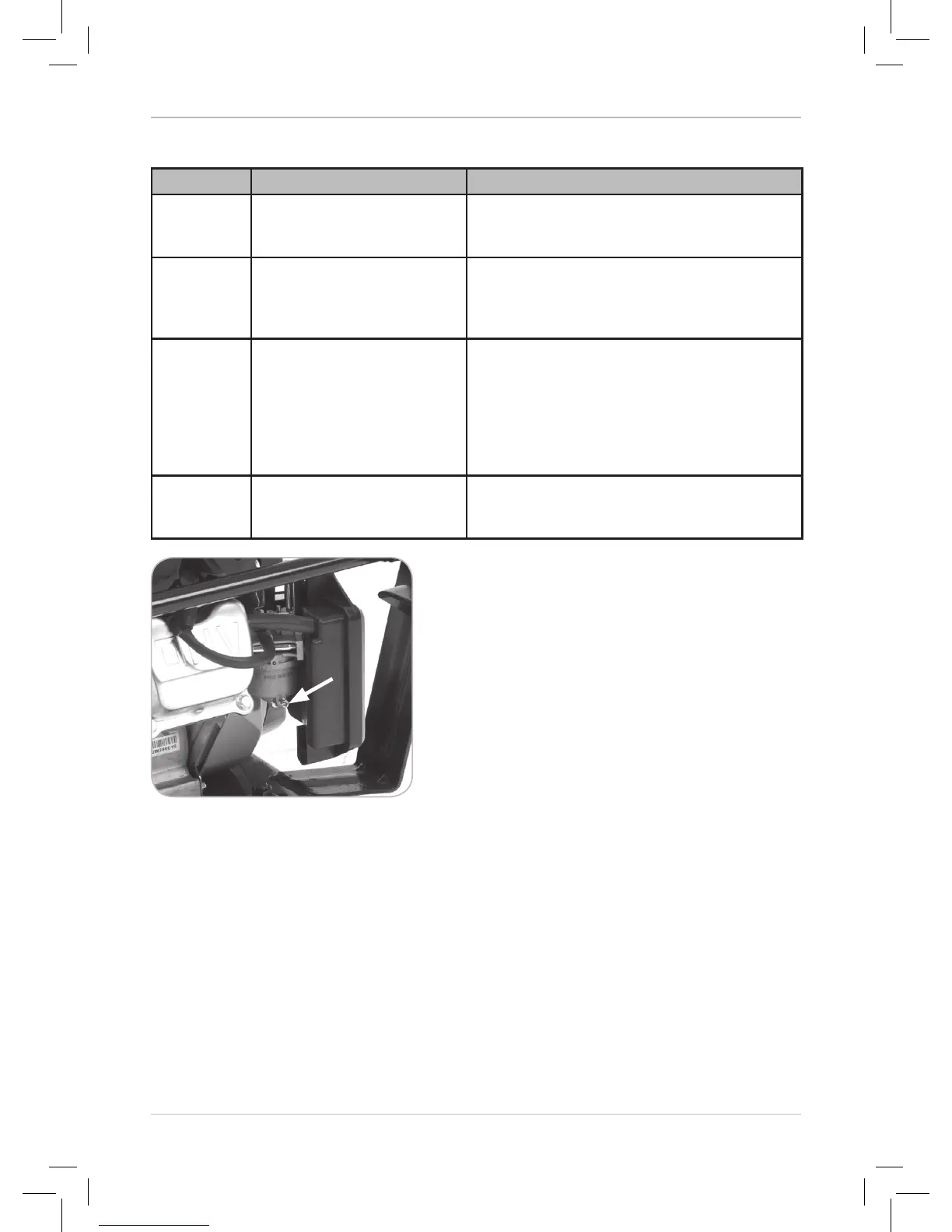

PROBLEM CAUSE POSSIBLE REMEDY

Paving

blocks

damaged.

Plate in direct contact with

the pavings.

Fit a ‘Hulk Paving Pad’.

Bituminous

surface

flaking

(laminating).

Over compactation. Remove and relay.

Low travel

speed.

Layer thickness too deep

(plate sinking).

Engine speed too low.

Moisture content of the

material too high or too low.

Remove some of the material so that the

layer thickness is reduced.

Increase engine speed slightly.

Remove the material and adjust the

moisture content.

Petrol

Hulk not

Travelling.

Engine speed too low. Increase engine speed slightly.

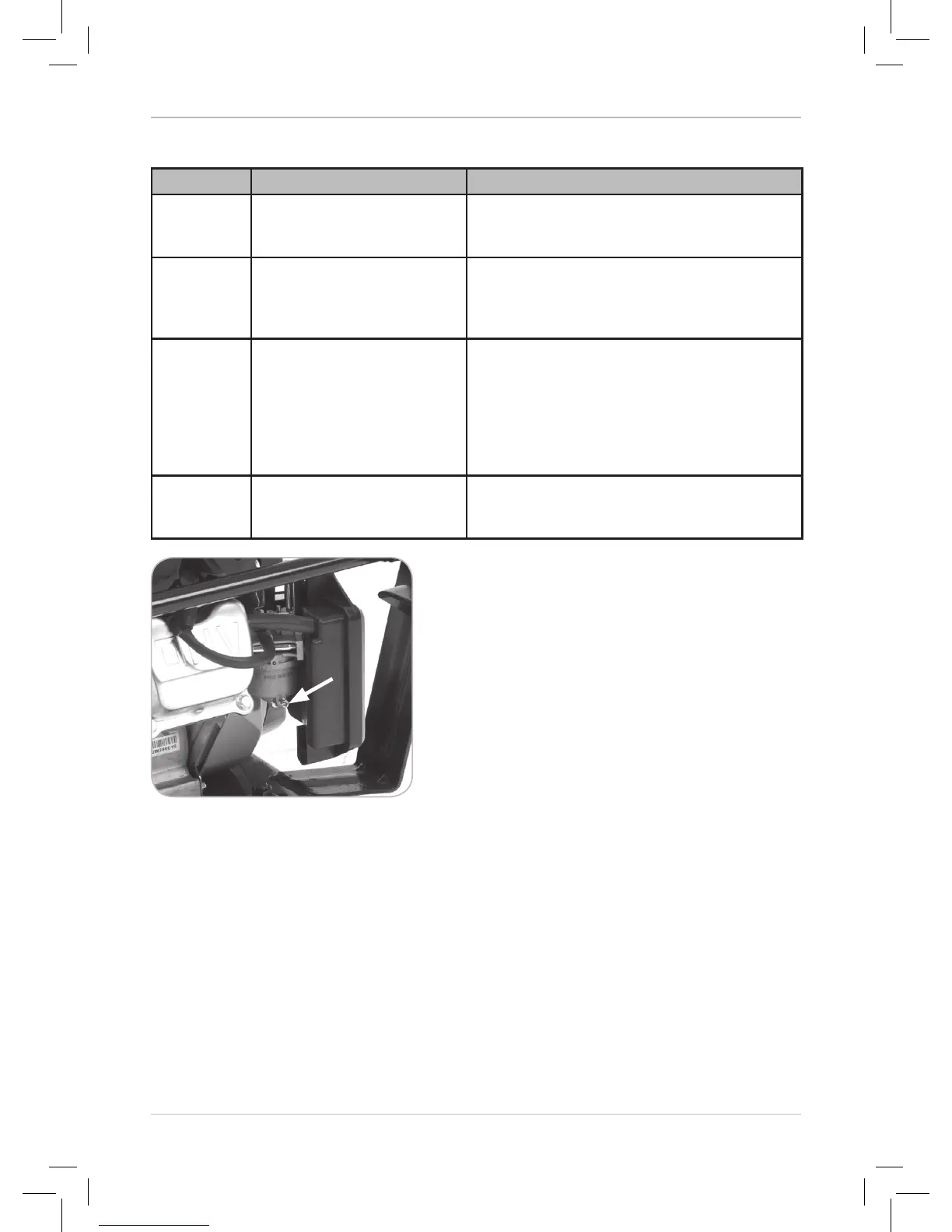

Fig. 18

LONG TERM STORAGE HULK PETROL

If your Evolution machine is not going to be used for a

period of 4 months or more (e.g. over the winter period)

the operator should consider preparing it for long term

storage. This will keep the engine in optimum condition

for re-commissioning when required.

• Drainallthefuelfromthefueltankandcarburettor

into a suitable approved container.

• Adraintapcanbefoundunderneaththecarburettor

float bowl. Loosen this tap to allow the fuel to drain

from the machine. (Fig. 18)

• Tightenthedraintapwhenallthefuelhasbeen

removed.

• Removethesparkplug.

• Pourapproximatelyonetablespoonofcleanengine

oil into the spark plug hole.

• Ensurethattheengineignitionswitchisinthe

‘OFF’ position.

• Gentlypulltherecoilstarterafewtimes.

• Replacethesparkplug.

• Gentlypulltherecoilstarteruntilresistanceisfelt

(this will mean that the piston is on its compression

stroke with both valves closed). Stop pulling the

recoil starter.

• Storetheengineinasecure,dryandwellventilated

location, under a cover to prevent dust, debris etc

from settling on the machine.

Loading...

Loading...