16. NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

17. CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine

that it will operate properly and perform its intended function – check

for alignment of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or

replaced.

18. Wear eye protection.

19. Keep hands out of path of saw blade.

20. Do not operate saw without guards in place.

21. Never reach around saw blade.

22. Turn off tool and wait for saw blade to stop before moving workpiece

or changing settings.

23. Disconnect power before changing blade, servicing or cleaning.

24. To reduce the risk of injury, return carriage to the full rear position after

each crosscut operation.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

ADDITIONAL SAFETY INSTRUCTION

1. Although compact, this saw is heavy. To reduce the risk of back injury,

get help whenever you have to lift the saw.

2. To reduce the risk of back injury, hold the tool close to your body when

lifting. Bending your knees so you can lift with your legs, not your

back. Lift by using the handhold areas at each side of the bottom of

the base.

3. Never carry the mitre saw by the power cord or the trigger grip of the

handle. Carrying the tool by the power cord could cause damage to

the insulation or the wire connections resulting in electric shock or

re.

4. Before removing the saw from the carton tighten the slide lock knob

to guard against sudden movement.

5. Place the saw on a secure stationary work surface and check the saw

over carefully.

6. Warning. Do not stare directly at the laser beam. A hazard may exist

if you deliberately stare into the beam, please observe all safety rules

as follows.

- The laser shall be used and maintained in accordance with the

manufacturer instructions.

- The laser beam shall not be deliberately aimed at personnel

and shall be prevented from being directed towards the eyes of a

person.

- Always ensure the laser beam is aimed at the workpiece

without reective surfaces, i.e. wood or rough coated surfaces are

acceptable.

- Do not change the laser light assembly with a different type.

SPECIFICATIONS

Model Rage 3

Motor (230v-240v ~ or 110v ~ 50/60 Hz) (Watts): 2000

RPM No Load (min-1): 2500

Recommended Maximum Duty Cycle (Minutes): 30

Sound Pressure Level (Under Load) (dB(A)): 98

Vibration Level (Under Load) (m/s

2

): 1.98

Weight: 19.6Kg

Blade Dimensions

Maximum Diameter: (10”) 255mm

Bore Diameter: (1”) 25.4mm

Thickness: (1/16”) 2mm

Maximum Cutting Capacity

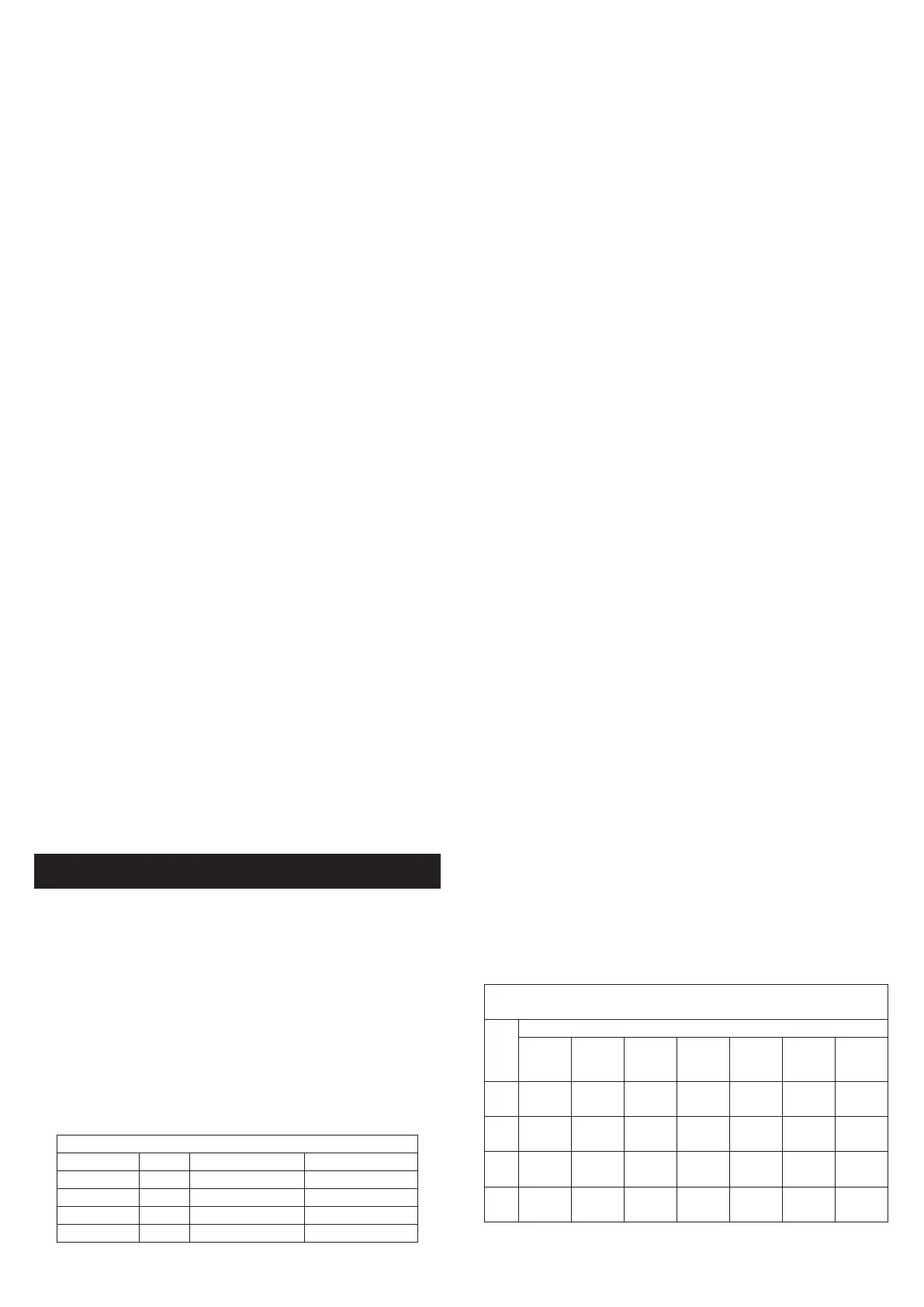

Mitre Bevel Max Width of Cut Max Depth of Cut

90º 90° 300mm (11.81””) 75mm (2.95”)

45°L / 45°R 45° 210mm (8.26””) 40mm (1.57”)

45°L / 45°R 90° 210mm (8.26””) 75mm (2.95”)

90° 45° 300mm (11.81””) 40mm (1.57”)

5. Turn on saw and allow the saw to reach full speed.

6. Press the lower guard unlock lever for saw head release.

7. Push the saw handle down and cut the workpiece.

8. After cut is complete turn off saw, allow blade to completely stop.

WARNING: For your convenient use, the saw has a blade brake. Never

rely on it to replace proper use of the guard on your saw.

BODY AND HAND POSITION

1. Never place hands near cutting area and keep hand away from the

path of blade.

2. Hold workpiece rmly to the fence to prevent movement toward the

blade.

3. Before making a cut. Make a dry run with the power off so you can

see the path of the blade.

5. Keep hands in position until trigger has been released and the blade

has completely stopped.

MITRE CUT

An angle of up to 45° left or right can be obtained using the unit.

1. Loosen the mitre angle lock.

2. Pull up the mitre angle set lever.

3. Turn the table unit to the desired angle is indicated on the mitre angle

pointer.

4. Tighten the angle lock knob to hold the desired angle.

5. Start the saw and allow it to reach full speed before commencing the

cut.

BEVEL CUT

1. Loosen the bevel angle lock.

2. Move the blade to desired bevel angle.

3. Stand to the left side of the handle to make the cut.

COMPOUND CUT

When a compound cut is required. Select the desired bevel and mitre

positions.

CUTTING BOWED MATERIAL (Fig 10 & 11)

Before cutting a workpiece, check to make sure it is not

bowed. If it is bowed, the workpiece must be positioned

and cut as illustrated. Do not position workpiece

incorrectly or try to cut the workpiece without the

support of the fence. This will cause pinching of the

workpiece on the blade. The workpiece could suddenly

jump or move and your hand could hit the blade.

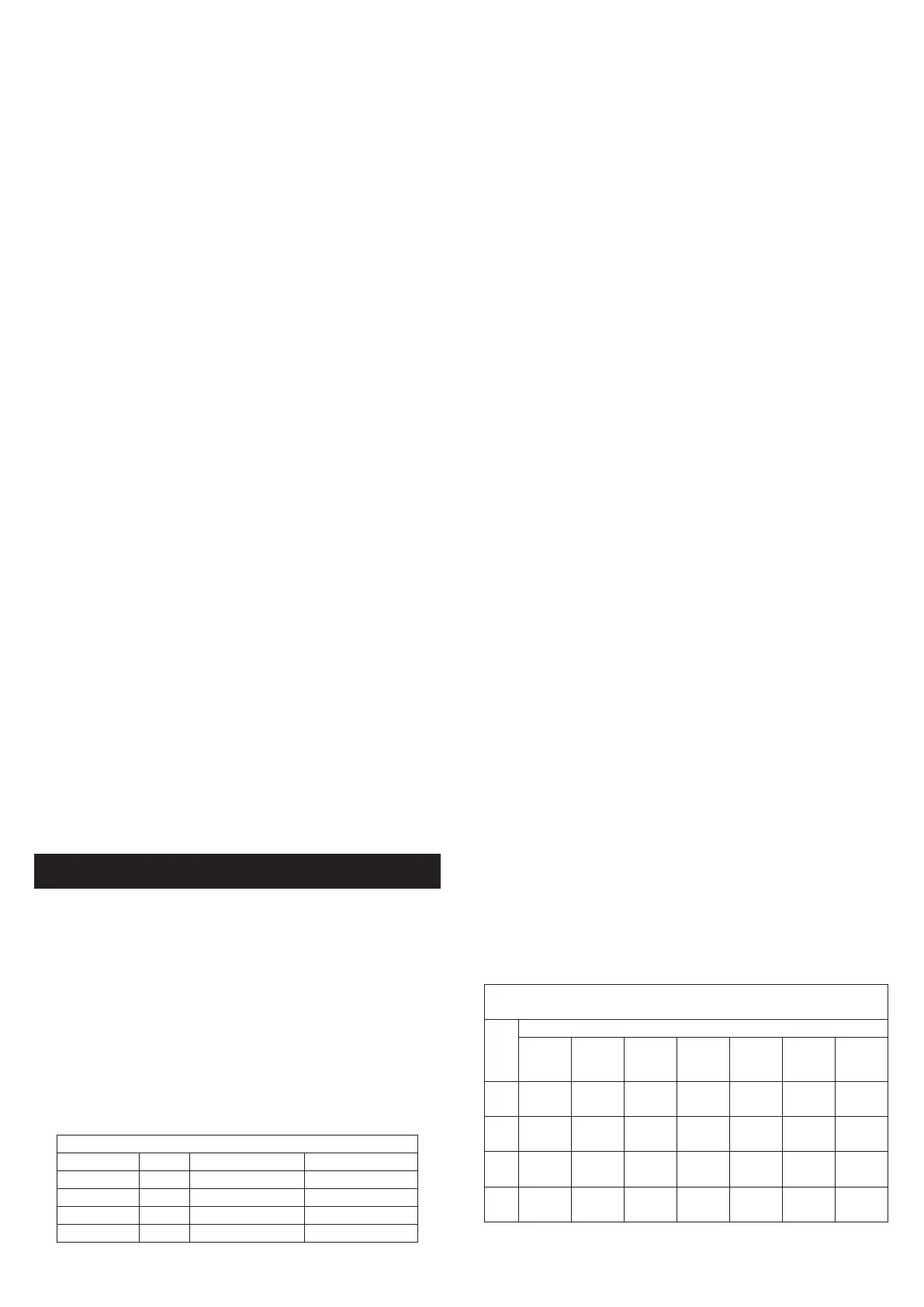

CUTTING COMPOUND MITRES

To aid in making the correct settings, the compound

angle setting chart below has been provided. Since

compound cuts are the most difcult to accurately

obtain, trial cuts should be made in scrap material, and

much thought and planning made, prior to making your

required cut.

WARNING: Always unplug the tool before making any

assembly, adjustments or changing accessories.

COMPOUND ANGLE SETTINGS FOR POPULAR STRUCTURES

Each B (Bevel) and M (Mitre) Setting is given to the closest 0.005°

PITCH

OF

SIDE

N U M B E R O F S I D E S

4 5 6 7 8 9 10

0°

M- 45.00°

B- 0.00°

M- 36.00°

B- 0.00°

M- 30.00°

B- 0.00°

M- 25.71°

B- 0.00°

M- 22.50°

B- 0.00°

M- 20.00°

B- 0.00°

M- 18.00°

B- 0.00°

5°

M- 44.89°

B- 3.53°

M- 35.90°

B- 2.94°

M- 29.91°

B- 2.50°

M- 25.63°

B- 2.17°

M- 22.42°

B- 1.91°

M- 19.93°

B- 1.71°

M- 17.94°

B- 1.54°

10°

M- 44.56°

B- 7.05°

M- 35.58°

B- 5.86°

M- 29.62°

B- 4.98°

M- 25.37°

B- 4.32°

M- 22.19°

B- 3.81°

M- 19.72°

B- 3.40°

M- 17.74°

B- 3.08°

15°

M- 44.01°

B- 10.55°

M- 35.06°

B- 8.75°

M- 29.15°

B- 7.44°

M- 24.95°

B- 6.95°

M- 21.81°

B- 5.68°

M- 19.37°

B- 5.08°

M- 17.42°

B- 4.59°

4 7

Loading...

Loading...