Caution

Raisingtherearoftheunitforassemblyrelying

solelyonmechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulicjacks

maynotbeenoughsupportormaymalfunction

allowingtheunittofall,whichcouldcause

injury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstandsor

equivalentsupport

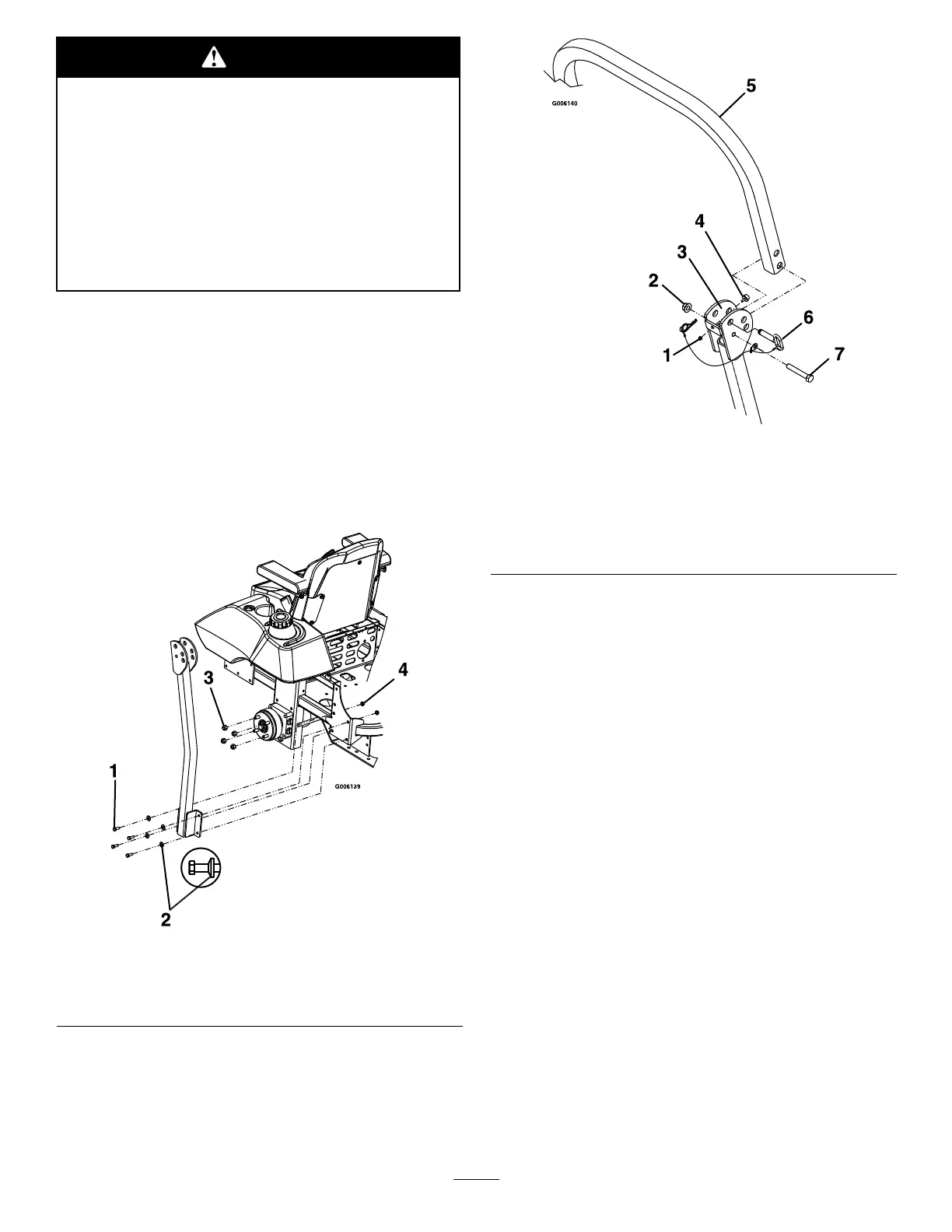

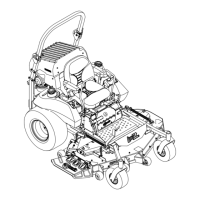

8.Locatetheleftandrightlowerrollbartubes.

9.Alignlowerrollbartubesalongrearengineframe

(Figure2).

10.Looselyinstalllowerrollbarhardware(four3/8-16

x1inchcapscrews,fourspringdiscwashersand

four3/8-16inchwhizlocknuts)tothetubesoneach

side(Figure2).

Note:Besurethespringdiscwasherconeis

installedtowardstheheadofthecapscrew.

Figure2

1.3/8-16x1inchcapscrews

3.Wheelnuts

2.Springdiscwasher(cone

towardscapscrewhead)

4.3/8-16inchwhizlocknuts

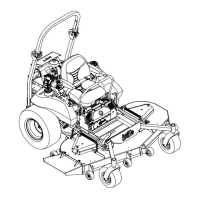

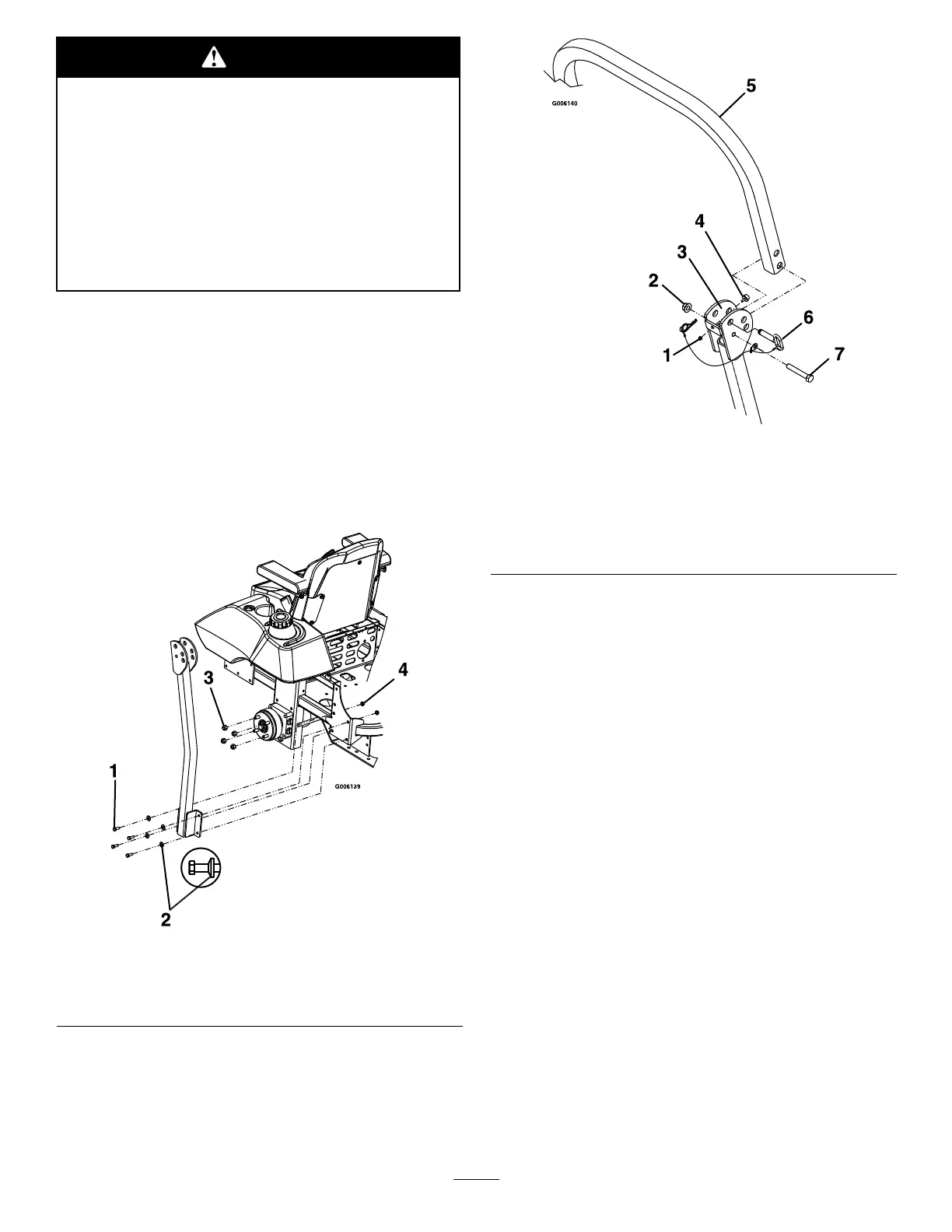

Figure3

1.1/4-20inchnylocnut

5.Upperrollbartube

2.1/2-13inchhexangelock

nuts

6.Latchpinassembly

3.Applyoiltoinsidesurface

ofearshapedholes

7.1/2-13x31/4inch

capscrew

4.Bumper

11.Locatethelatchpinassemblies(pinandhairpin

connectedwithalanyard).

12.Inserta1/2-13x31/4inchcapscrew(removedin

step5)intothebenttabwasheronthelanyardof

eachpinassembly(Figure3).

Note:Makesurethebenttabinthewasheris

towardstheheadofthebolt.

13.Lightlyoiltheinsidesurfacesoftheear-shaped

platesattheupperendofthelowerrollbartubes

(Figure3).

14.Locatetheupperu-shapedsectionoftherollbar.

Installtheupperrollbarsectionusingthetwo1/2-13

x31/4inchcapscrewsandtwo1/2-13inchhex

angelocknuts(removedinstep5).Donotover

tighten.Makesureupperrollbarcanpivotfreely.

Note:Makesurethecapscrewandnutsareinstalled

withthenuttotheinsideoftherollbar.

Note:Makesurethetabonthelanyardwasheris

installedasshownandpointstowardthefrontof

theunit.

15.Raisetherollbarintotheuprightpositionandsecure

withthelatchpinassembliesoneachside.Install

2

Loading...

Loading...