15

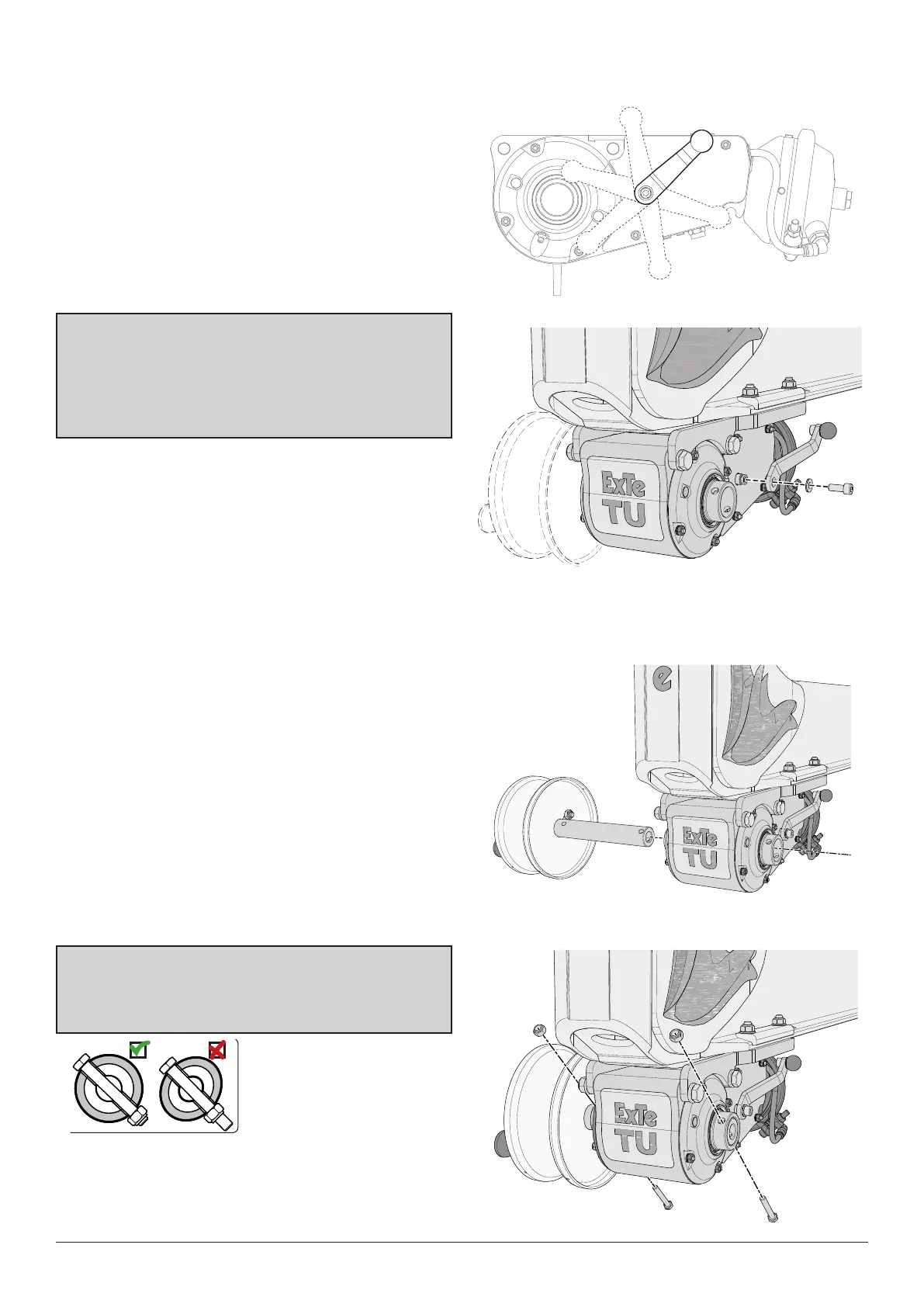

Fitting the disengaging lever.

The disengaging lever can be tted in six dierent

positions at intervals of 60 degrees to t existing

space. Tighten the screw with a torque wrench.

Tightening torque 25 Nm.

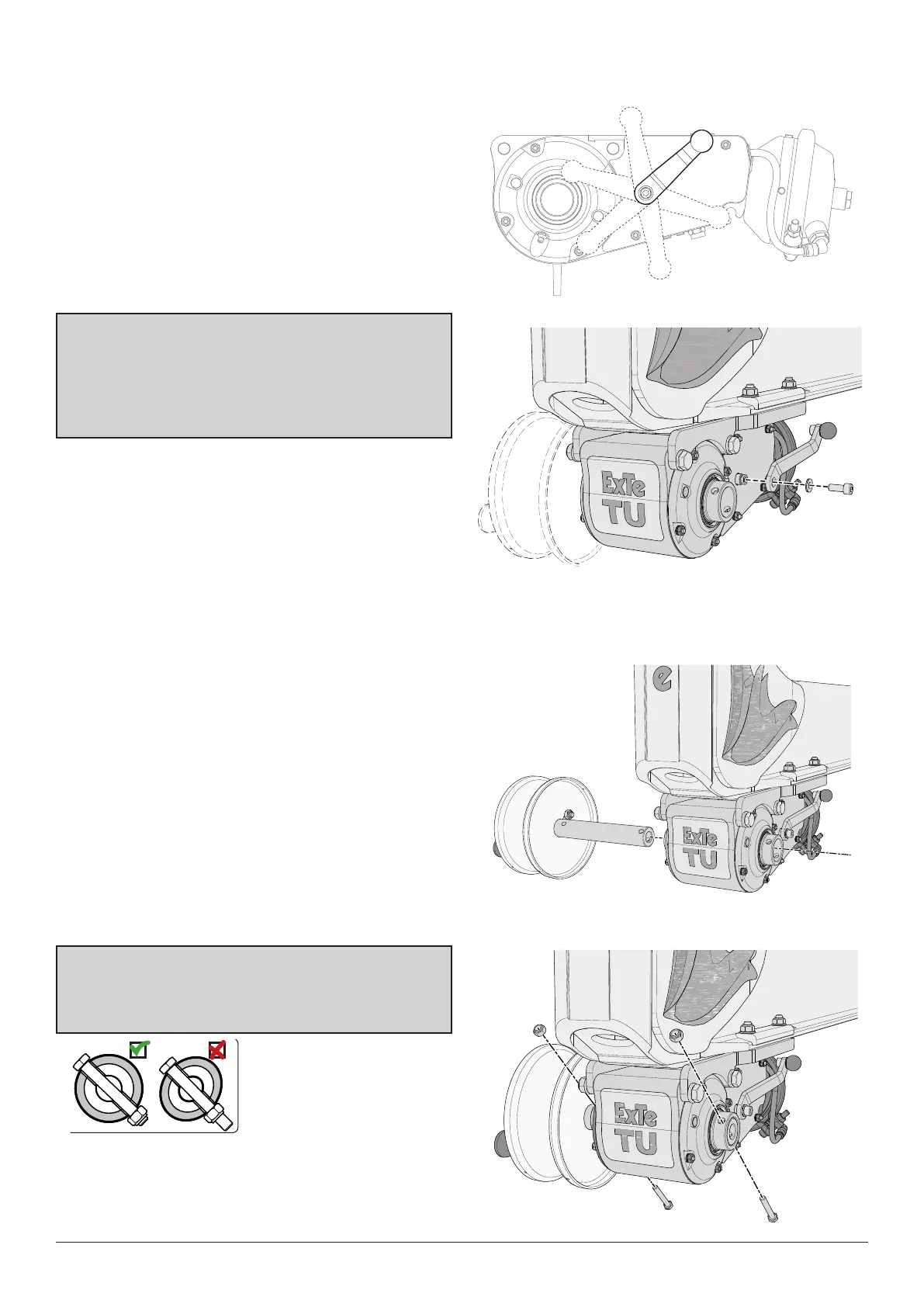

Installation of drum

In this example, a large 50 mm drum is being tted.

Other drums are tted in a similar way.

1. Run the drum shaft through the

tensioner drive shaft.

2. Secure the drum with the screw kit supplied.

3. Tighten the screws so that there is an extremely

small gap in the joint against the shaft.

m Warning!

The disengaging lever and drum shall be tted on

opposite sides of the tensioner. This is to avoid

a loose strap being caught in the lever, which

can lead to unintended disengagement during

operation.

m The screws that hold the drum should be tight-

ened gently. If the screws are too tight, the shaft

may become oval and the tensioner will operate

sluggishly.

Max 7 Nm

Loading...

Loading...