21

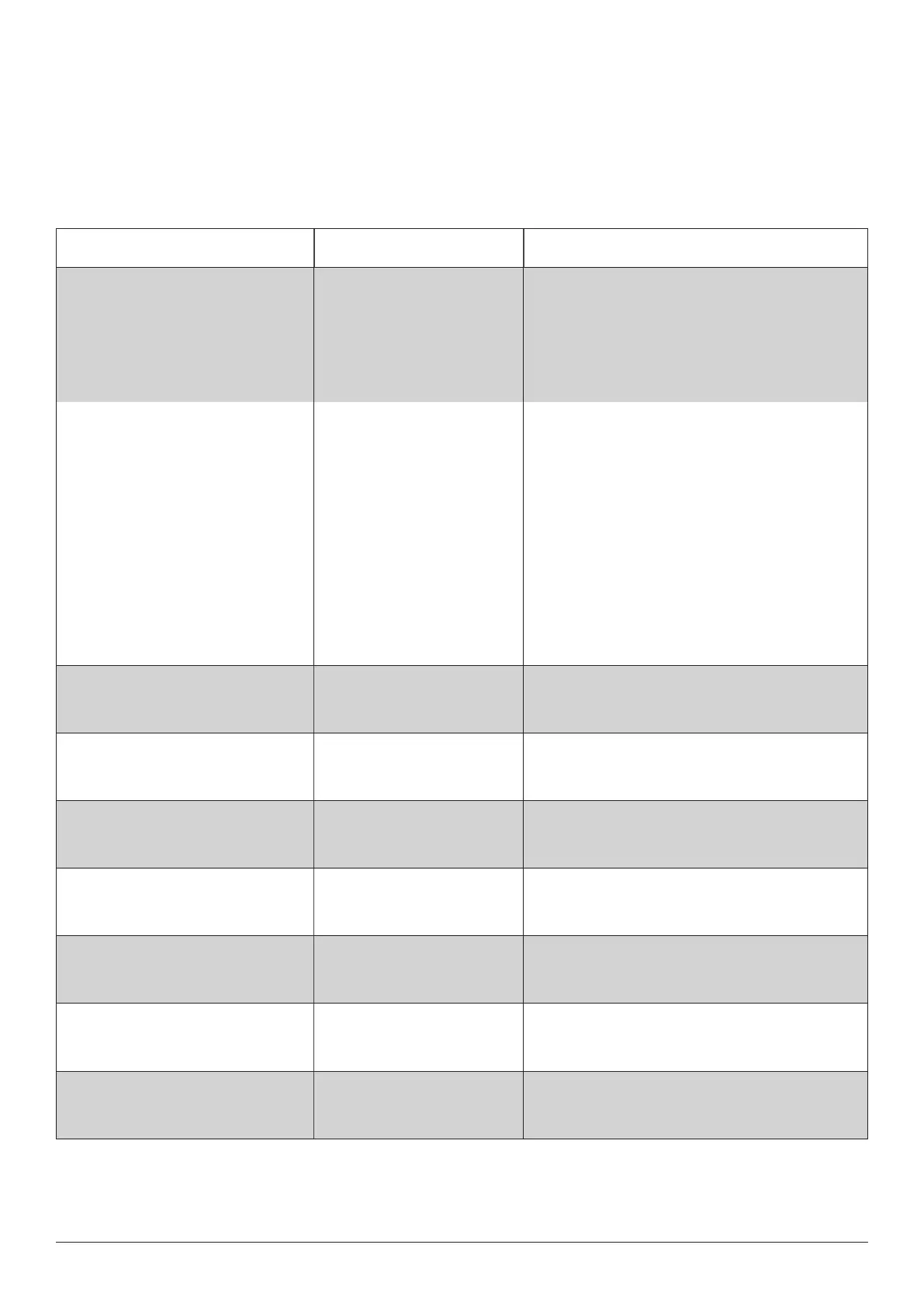

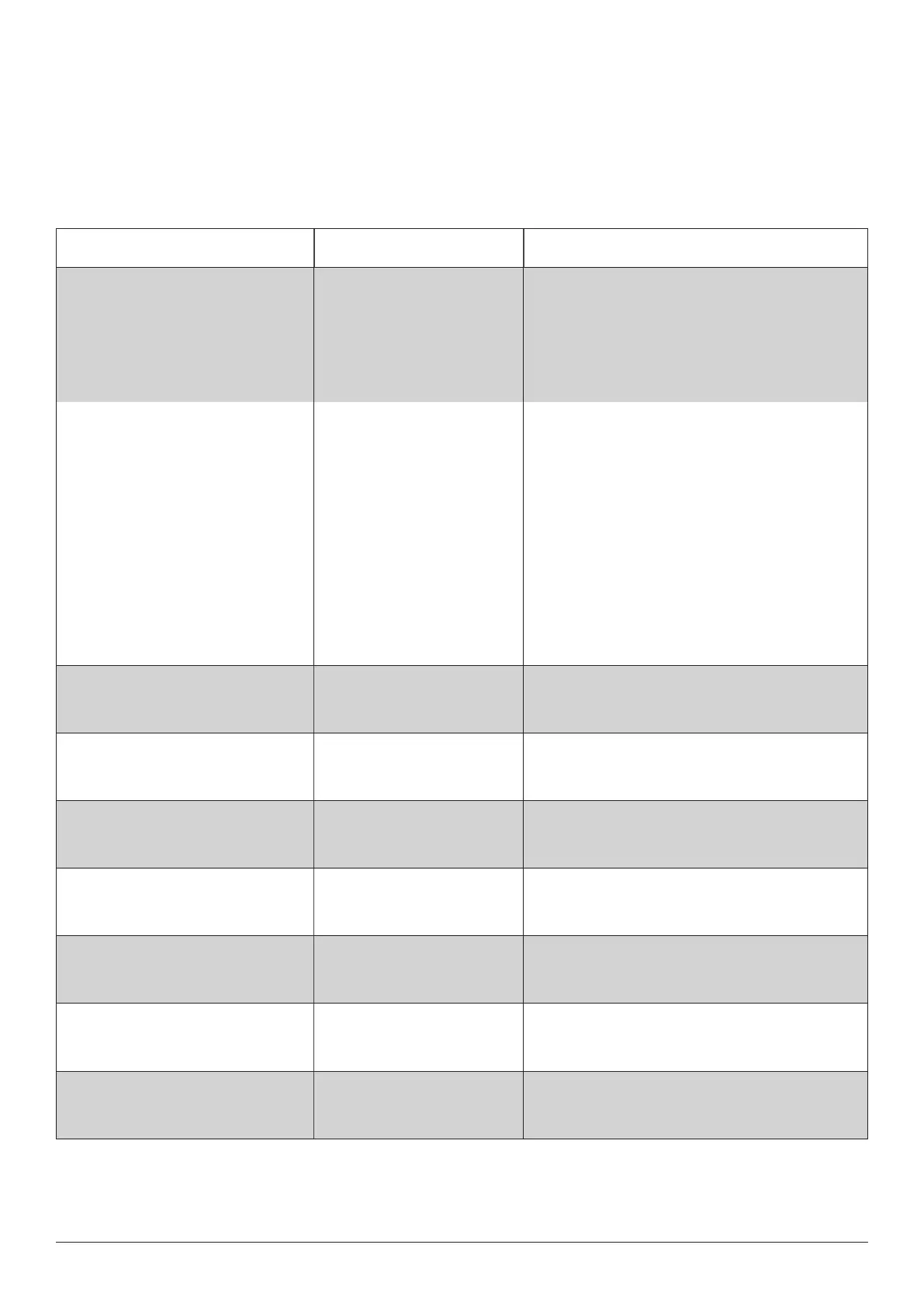

Problem Cause Solution

Insucient tensioning of

lashing

• Low air pressure • Make sure that the correct pressure is

supplied to TU. See “Recommended

working pressure” on page 7.

Adjust if necessary

• Ensure that air hoses and valves

are airtight. Fix any leaks

• The tensioner jams • Ensure that nothing (snow,

ice, mud etc.) is preventing the

movement of the TU’s shaft

• Ensure that drainage holes are

not clogged. If this is the case, the

inside of the tensioner may need

to be checked, which must be done

by a trained service technician

• TU is not greased; see page. 10

• TU is lubricated with the wrong

type of grease; see page 10

The tensioner is sluggish

in some situations

• Screws of the drum

tightened too hard

• Check torque on M8 screws holding drum

Noise in tensioner

(when valve shut o)

• Compressed

air not drained

through air valve

• Check the drainage in the air valve

Tensioner jammed/silent

(when valve shut o)

• Compressed air not

drained (via valve)

• Check the drainage in the air valve

Tensioner operating but

ratchet does not get a hold or

tighten

• Tensioner disengaged • Place disengaging lever in

operating position

Tensioner runs slowly • Low air ow to

tensioner

• Check the air hoses to the

tensioner to make sure no hose

is weighted/pressed together

Tensioning of sling too hard • Air pressure too high • Make sure that the correct pressure

is supplied to TU. See “Recommended

working pressure” on page 7.

Tensioner sluggish

(if bracket moved up)

• Bushing in bracket

loose/worn

• Replace bushing in bracket

Loading...

Loading...