WARNING LIGHT: Connect a warning light to terminals

22 and 23 in the group labeled W.LIGHT in terminal

block J3. The terminals provide an output voltage of 30

VDC, maximum power 3 Watts. This output voltage will

power most 24 VDC warning lights.

Note: The behavior of the warning light varies

according to the logic you have set:

Logics A, S, E, EP, and B: The warning light is

on steadily during opening and the pause

phase. During closing, the light flashes.

Logic C: The warning light is on steadily during

opening and flashes during closing.

SET OTHER OPERATING CONTROLS

WARNING! Turn off the main power before you

make any electrical connections or set any

switches inside the control panel box.

You need to set DIP switches and adjust the

potentiometers on the control panel for your gate's

operation. The 450 MPS Control Panel has 5 DIP

switches and 4 potentiometers that control a wide range

of functions.

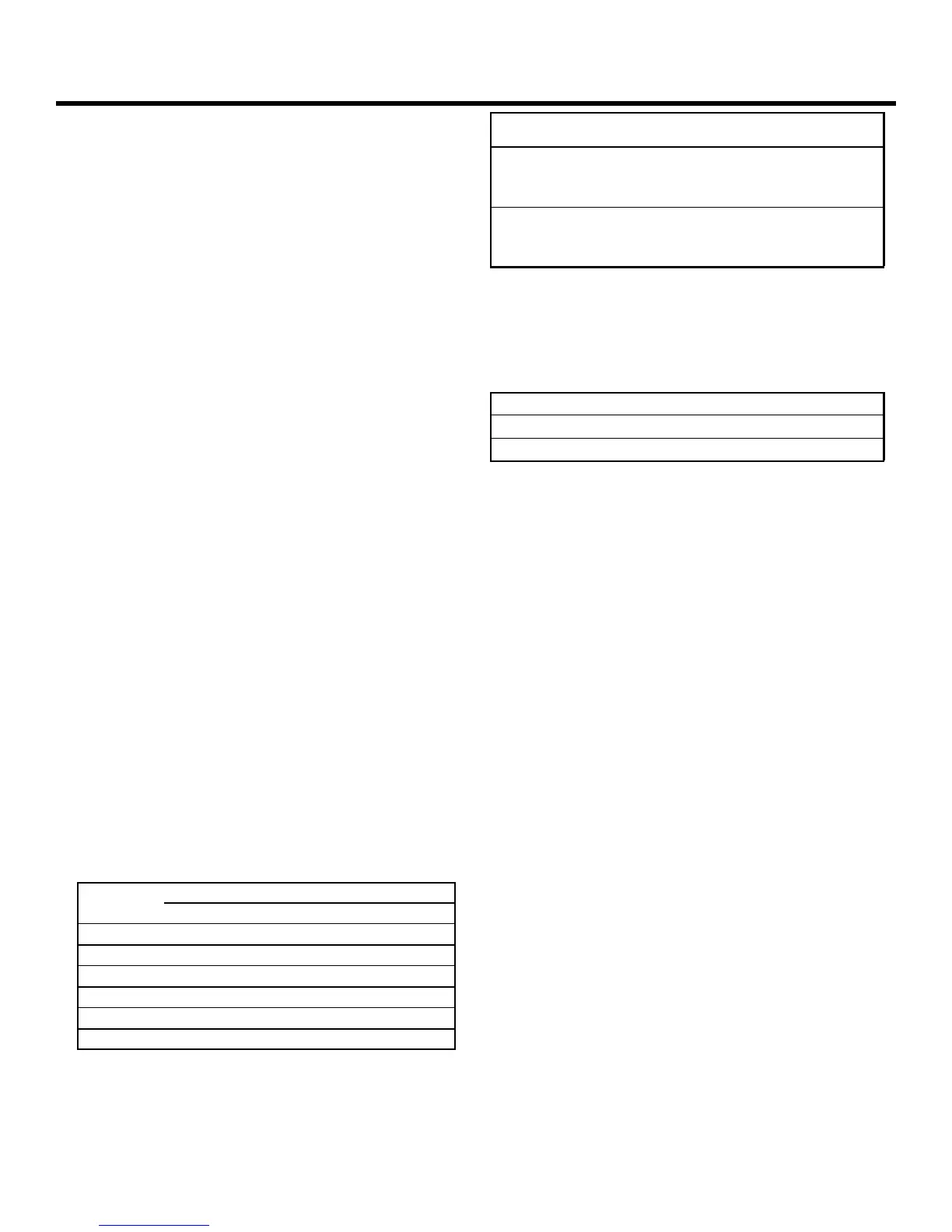

SET DIP SWITCHES

Switches 1, 2, and 3 (Operating Logic): The 450

MPS Control Panel offers six operating modes: A, S, E,

EP, B, and C. For more details about the logical modes,

refer to the operating modes previously listed in this

manual.

Switches 1, 2, and 3 control the operating logic

according to the following scheme:

Switch 4 (Reversing Device Behavior on

Closing):

Refer to the operating logic tables earlier in

these instructions and to the following table for how to

set DIP switch 4.

SWITCH 5 (REVERSING STROKE): Sometimes electric

locks require a reversing stroke to disengage the lock. If

your gate does not always open because your lock is

hanging up, you may want to activate the Reversing

Stroke.

Adjust the Potentiometers

The four potentiometers control the torque, the pause

time, the opening/closing time of operation, and the

leaf delay on closing.

TORQUE: The torque potentiometer on the 450 MPS

must be turned all the way clockwise for the 402

Operator. The potentiometer is for the FAAC Model 412,

a screwdrive operator. The torque potentiometer cannot

be used to adjust the operator’s hydraulic operating

pressures.

CAUTION: Failure to turn the torque

potentiometer to maximum in the clockwise

direction jeopardizes the life of the motor of

your operator.

WARNING! Adjust the operating pressure on

the 402 Operator only by means of the

hydraulic bypass valve screws. See pages 12

and 20.

PAUSE TIME: The pause time between opening and

closing can be adjusted from 0 to 240 seconds. Turn

the potentiometer clockwise to increase the pause time

and counterclockwise to decrease the pause time.

OPENING/CLOSING TIME: The opening/closing time is

adjustable from 10 to 62 seconds. The approximate

opening/closing time for a 90-degree opening is about

12 seconds. Turn the potentiometer clockwise to

increase the time and counterclockwise to decrease the

time.

For optimal operation, set the time so that the motor

remains active for a couple of seconds after the leaf has

reached its limit stop for opening and for closing.

Page 18

August, 2002

402 Installation

Logic

1 2 3

A on off on

S on off off

E off on off

EP on on off

B on on on

C off off on

DIP Switch

Gate Behavior During Closing DIP Switch 4

Gate immediately reverses its

direction

off

Gate stops and reverse its

direction when reversing

device is no longer triggered

on

Reversing Stroke DIP Switch 5

Not activated off

Activated on

Loading...

Loading...