7

FAAC Model S418 Swing Gate Operator

Technical Specications S418

Power Supply (VDC) 24

Nominal Power (W) 35

Absorbed Current (A) 1.5

Maximum Thrust Force (daN) 180

Stroke (inches) 17.75

a

Speed (inches/sec) 0.75

Maximum Size of Leaf (inches) 106

b

Type and Frequency of Use at 68°F 80 cycles/day

Consecutive Cycles at 68°F 30

Ambient Operating Temperature (°F) -4 to 131

Operator Weight (lbs) 13.2

Protection Class IP54

Operator Dimensions See g. 2

a

If you do not wish to use the mechanical stops on opening

and closing, the operator stroke becomes 15.25 inches.

b

With leaves of over 90.5 inches, an electric lock must be

installed to ensure locking of the leaf.

2. TECHNICAL SPECIFICATIONS

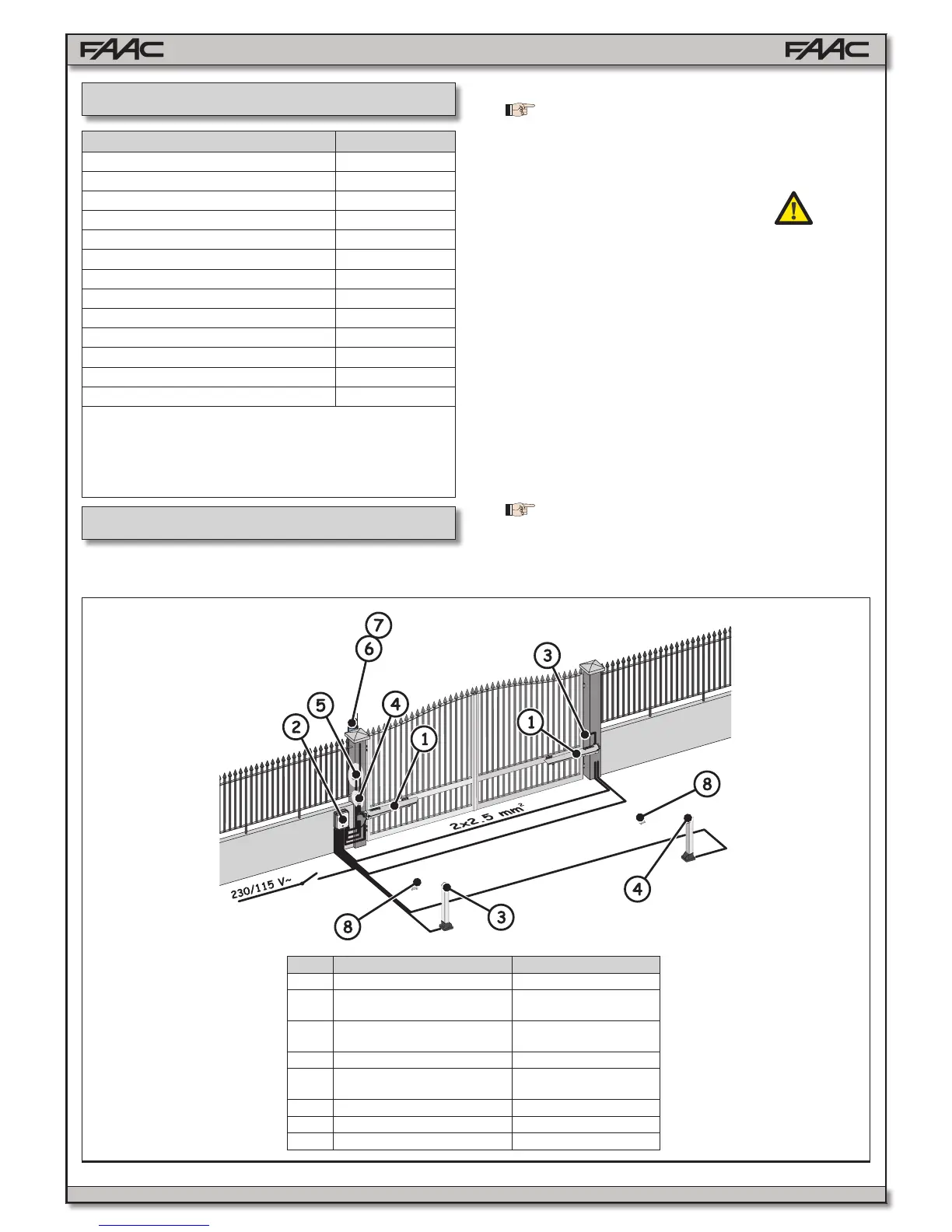

3. INSTALLATION

When laying electrical cables, use conduits with

adequate rigidity and/or exibility.

To avoid any type of interference, we advise you

to always separate low-voltage accessories and

command connection wiring from power supply cables,

use separate sheaths.

3.2 PRELIMINARY CHECKS

The structure of the gate directly inuences the reliability

and safety of the automated system. To ensure correct

operation, the structure of the existing gate, or that to be

tted, must have the following characteristics:

• The length of leaf must conform to what is shown in the

technical characteristics of the operator (Section 2).

• The structure of the leaves must be sturdy and rigid,

suitable for an automated system.

• There must be regular and uniform movement of the

leaves, with no friction or sticking along their entire

movement.

• Hinges must be suitably sturdy and in good condition.

• Mechanical opening and closing stop-points must be

present on the ground (not necessary if mechanical

operator stops are used).

It is recommended that any metalwork operations

should be performed prior to installing the automated

system.

3.1 ELECTRICAL PREPARATIONS SETUP

Fig. 3

Part Description Cables

1 Operators Supplied

2 Control Unit

3x1.5 mm

2

(Power Supply)

3 TX Photocells

4x0.5 mm

2

(2x0.5 mm

2

Bus)

4 RX Photocells 2x0.5 mm

2

5 Key Selector

2x0.5 mm

2

(1 contact)

3x0.5 mm

2

(2 contacts)

6 Flashing Lamp 2x1.5 mm

2

7 External Antenna Coaxial Cable

8 Mechanical Stops

Loading...

Loading...