Bladsy/ Page 6

GHRIES ALBEI KRUISKOPPELINGS OP DIE KRAGAFTAKKERAS

Geen kragaftakkeras kan sonder ghries werk nie! Dit is noodsaaklik dat die as se twee

kruiskoppelings aanvanklik volledig te ghries, en dan geghries te hou. Verseker dat die ghries

uit al vier koppies van die kruis stoot, elke keer wanneer dit geghries word. Ghries ook die twee

glybuise.

STEL DIE GLYKOPPELAAR TOT DIE KORREKTE WRINGKRAG

Meeste Falcon-kapploeë is met ‘n glykoppelaar toegerus. Dit is tot die korrekte wringkrag gestel,

sodat dit onder oormatige ladings kan gly en jou implement teen permanente meganiese skade

kan beskerm.

Indien dit vir lang periodes oorlaai word, sal die glykoppelaar gly en oortollige hitte weens wrywing

genereer. Tekens van oormatige gly is rook, brandreuke of poeierreste in die omgewing van die

glykoppelaar, of verkleuring van die glykoppelaareenheid. Onder normale werkstoestande moet

die temperatuur van die glykoppelaareenheid dus nie warmer wees as die temperatuur van die

implement se ratkas nie.

Die glykoppelaar sal dalk in geval van die volgende opgedoen “opgeknap” moet word:

• die wrywingplate is geslyt of uitgebrand vanweë langdurige oorlading

• ghries, olie of diesel het die glykoppelaarmeganisme gekontamineer

• die implement het lank gestaan, wat die waarskynlikheid van roes in die

glykoppelaarmeganisme kan verhoog.

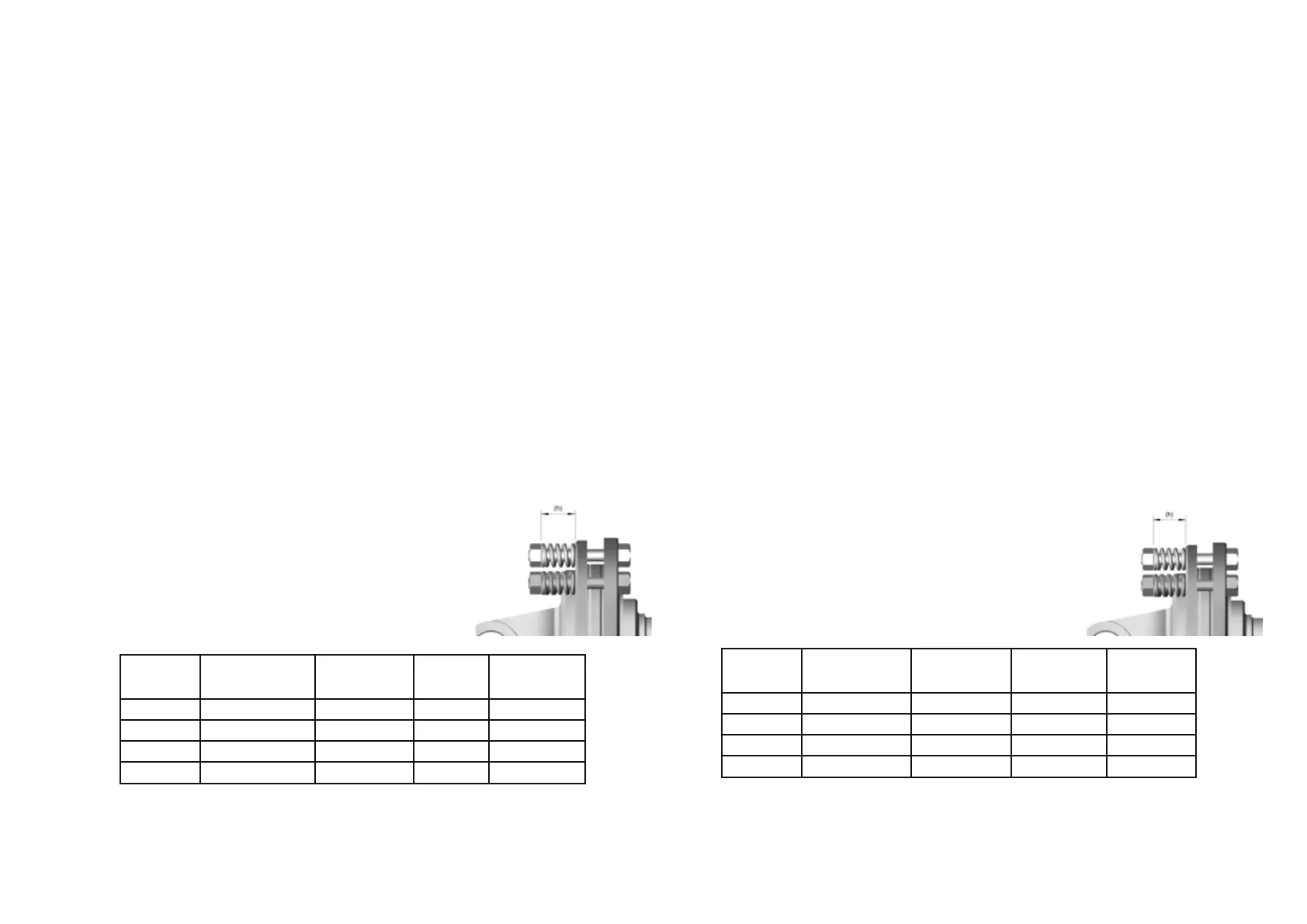

Wanneer die glykoppelaar opgeknap word, verseker dat slegs

oorspronklike onderdele gebruik word soos op bladsy 55 van

hierdie handleiding uiteengesit. Gebruik altyd die veer-instellings

wat in die tabel hier onder aangedui word om akkurate verstelling

te verseker. Draai elke keermoer agtereenvolgens met ‘n halfdraai

totdat die betrokke instelling bereik is.

Alle Falcon-wentelsnyers is ontwerp om teen 540 opm te loop. Die wentelsnyer moet hoër gelig

word as die materiaal wat gesny gaan word, en dan moet die kragaftakker gekoppel word.

Sodra dit gekoppel is, moet die opm tot 540 verhoog en dan tydens die snyery daar gehou word.

Versuim om dit te doen sal die wringkragvlakke op sowel die trekker as die wentelsnyer verhoog,

wat tot ‘n korter glykoppelaarlewe sal lei.

GREASE BOTH UNIVERSAL CROSSES OF THE PTO SHAFT

The PTO shaft can not operate without grease! It is essential that the two crosses of the shaft are

fully greased initially and kept greased thereafter. Ensure that the grease pushes out of all four

cups, of each cross, every time it is greased. Also grease the two sliding tubes.

SLIP-CLUTCH OPERATION AND MAINTENANCE

Most Falcon Slashers are tted with a slip-clutch. This is required to slip under excessive load at a

specic pre-set torque in order to prevent permanent mechanical damage to the implement.

If overloaded for sustained periods the slip-clutch will slip and generate excess heat through

friction. Excessive slipping may be detected through smoke, burning odours or powder residues

in the vicinity of the slip-clutch, or discoloration of the slip-clutch assembly. So under normal

operating conditions the slip-clutch assembly temperature should not exceed that of the

temperature of the implement’s gearbox.

The slip-clutch may need to be overhauled in the event of any of the following:

• the friction plates are worn or burned out due to sustained overloading

• the slip-clutch mechanism has become contaminated by grease, oil or diesel

• the implement has stood for an extended period, increasing the likelihood of corrosion in the

slip-clutch mechanism.

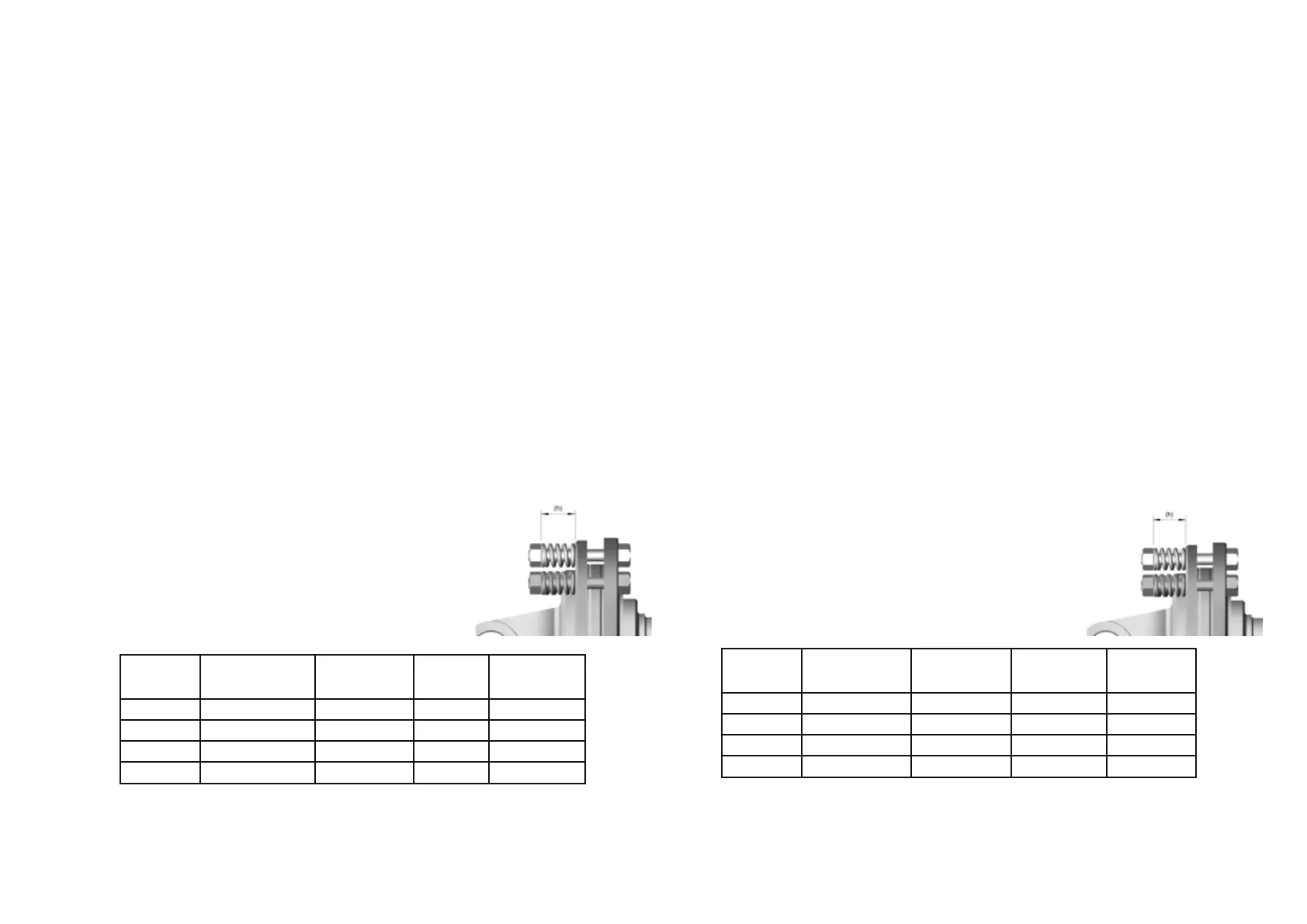

When overhauling the slip-clutch, be sure to use only original

parts as listed on page 55 of this manual. Apply the spring

preload settings indicated in the table below to ensure accurate

adjustment. Tighten each retaining nut successively by one half-

turn until the relevant setting is achieved.

All Falcon Slashers are designed to run at 540 rpm. The slasher should be raised above the

material that is to be cut and then the tractor PTO is to be engaged. Once engaged, the rpm

should be increased to 540 and then maintained at that level while cutting. Failing to do this will

increase the torque levels on both the tractor and the slasher, resulting in a shorter slip clutch life.

3. 3.

4.

4.

Category

OEM, clutch

assembly

OEM, spring

Number of

springs

Spring

length, (h)

B4-FF1 146.241.011 180.014.022 8 32.0mm

B6-FF2 146.262.011 180.019.017 8 32.9mm

B6-FF4 146.264.011 180.014.022 8 31.2mm

B8-FF4 146.284.011 180.014.022 8 31.2mm

Kategorie

OGV, koppelaa-

reenheid

OGV, veer

Aantal

vere

Veer

lengte, (h)

B4-FF1 146.241.011 180.014.022 8 32.0mm

B6-FF2 146.262.011 180.019.017 8 32.9mm

B6-FF4 146.264.011 180.014.022 8 31.2mm

B8-FF4 146.284.011 180.014.022 8 31.2mm

Loading...

Loading...