22

GND

ORG

RED

BLK

GND

L1

L2

L3

2

SW2

1

J23

1

SW3

SW6

34

0

1

2

3

4

5

6

7

8

9

1

9

0

SW1

3

4

2

SW2

5

6

7

8

21

5

4

3

SW3

3

2

1 6

54

8

7

SW6

1

43

2

7

6

5

8

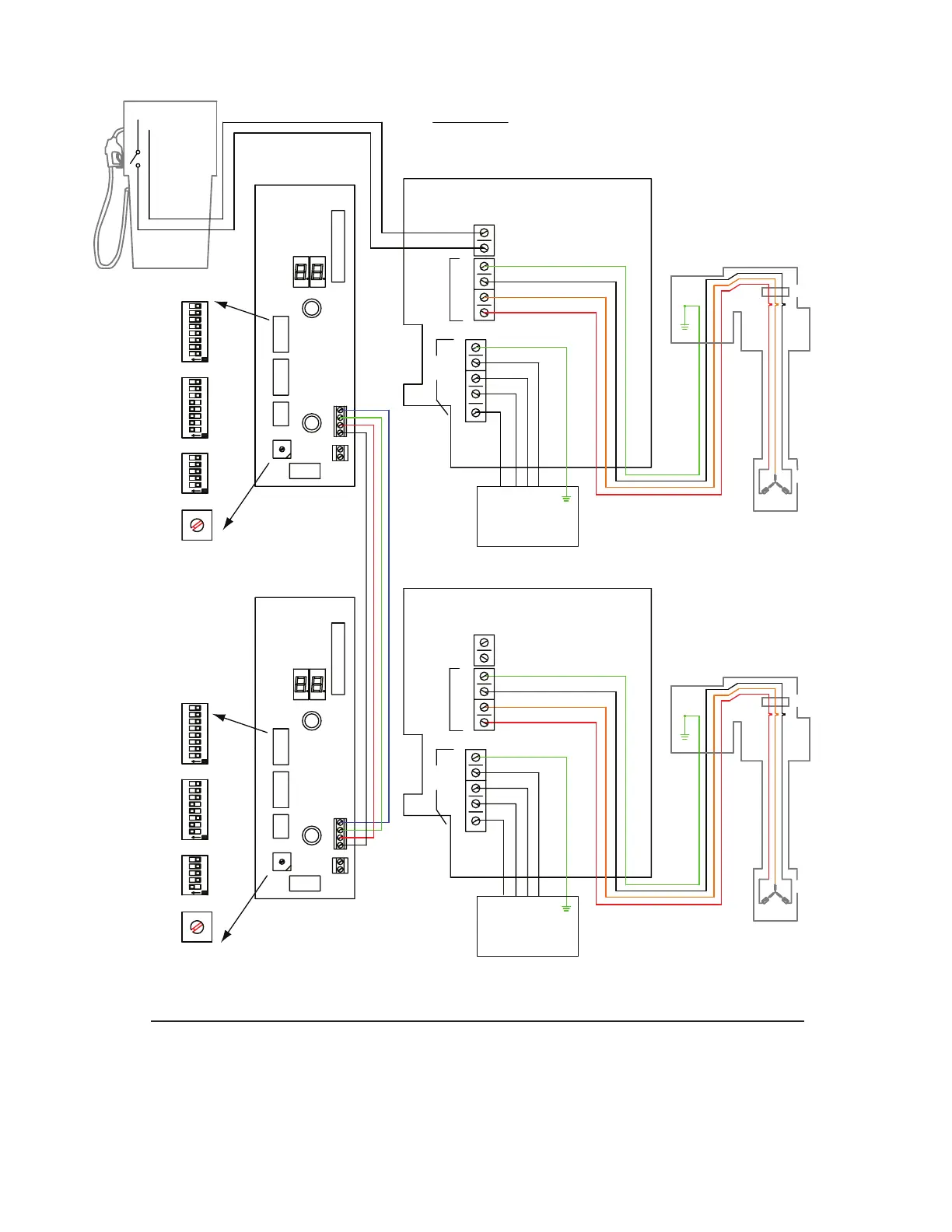

Switch

Handle

Dispenser

Return

110VAC or 240VAC SUPPLY

THERMAL

OVERLOADS

PMAMVS2

CONNECTOR

BLACK

RED

ORANGE

PLUG

O

N

O

N

O

N

INCOMING POWER

3 PHASE, 50 OR 60 Hz

360 -440 VAC

EcoVFC

Field wire panel

User interface panel

Wire Diagram for EcoVFC with PMAVS2

Stand Alone

Note: see product installation

instructions for further

details. Wiring must conform

to all federal, state, and

local codes. Control panels

are for non-hazardous, indoor

use only.

TO MOTOR

TO

LINE

L3

N

L2

L1

GND

BLK

RED

ORG

GND

5

SW1

0

3

2

7

4

6

1

9

8

O

N

SW2

12

3

5

4

0

1

2

3

4

5

6

7

8

9

SW3

SW2

1J23

1234

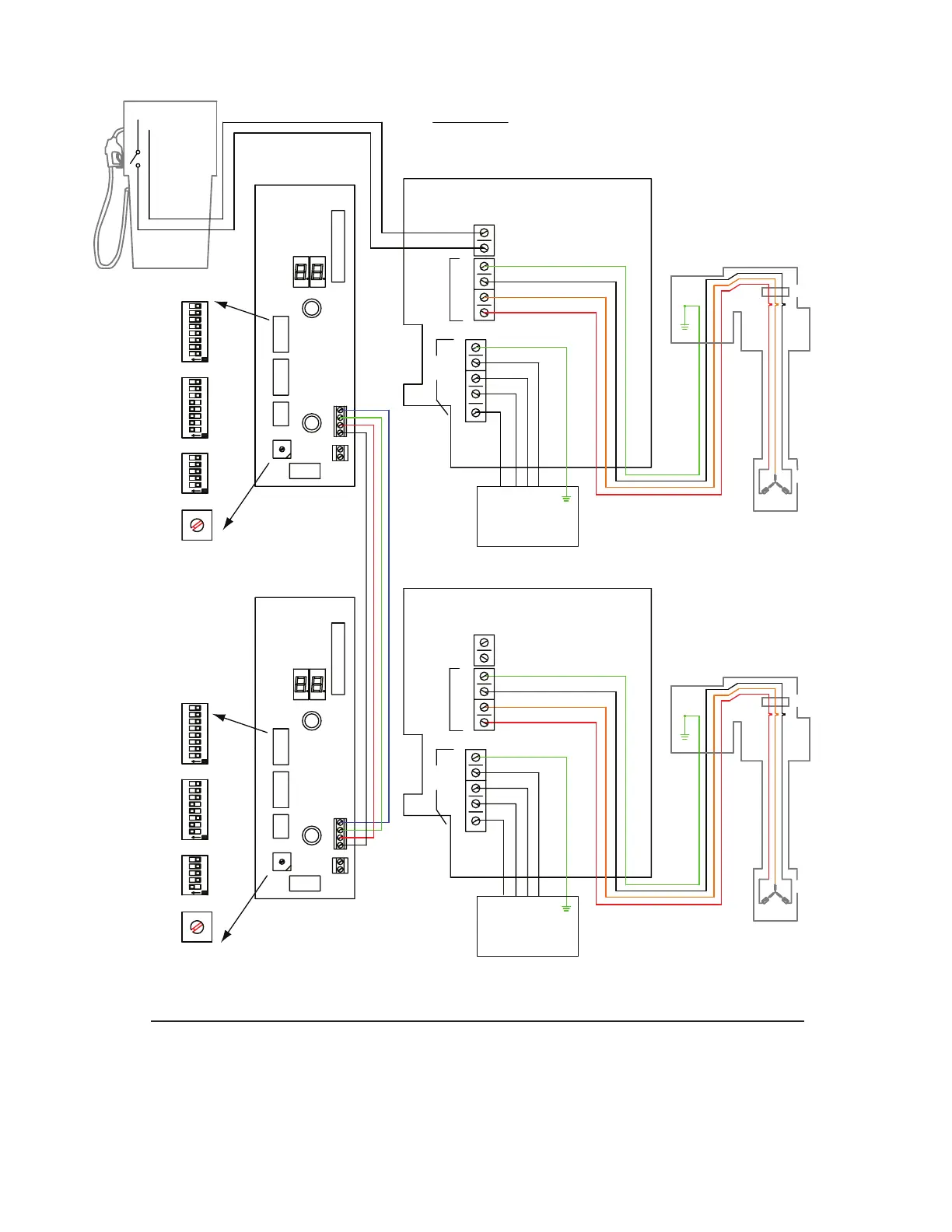

TO

LINE

USER INTERFACE PANEL

8

O

N

SW3

3

2

1

54

7

6

O

N

SW6

1

43

2

5

6

SW6

Switches located on

user interface panel

Switches located on

user interface panel

78

TO MOTOR

OVERLOADS

INCOMING POWER

3 PHASE, 50 OR 60 Hz

360 -440 VAC

THERMAL

PMAMVS2

ORANGE

BLACK

EcoVFC

Field Wire Panel

RED

CONNECTOR

PLUG

Note: see installation and

owners manual for further

details of switch settings

and EcoVFC calibration

settings of SW1 rotary

must match on Master and

Slave units.

position and SW3 poles 4 & 5.

N

Figure 9 - Master/Slave conguration of EcoVFC with 2 horsepower variable speed (VS2)

(for connecting with VS4 pumps, turn SW3 Pole 6 ON for controller connected)

Loading...

Loading...