Do you have a question about the Festo MPS PA and is the answer not in the manual?

National regulations and supervisor requirements for safe operation of electrical systems and equipment.

Explanation of DANGER, WARNING, and CAUTION symbols and their associated hazards.

Specifies that Festo Didactic systems are for teaching and training applications only.

Essential safety instructions and regulations for safe handling and operation of components.

Responsibilities of the operating company and trainees regarding safety and training.

Hazards and precautions when handling system components to prevent injury or damage.

General guidelines for trainees, instructors, and workplace safety.

Safety instructions specific to working with the mechanical components of the system.

Critical safety instructions for electrical systems, including shock prevention and grounding.

Safety guidelines for pneumatic components, pressure, and tubing.

Safety precautions for operating the process technology, including filling and media.

General technical specifications, operating parameters, and dimensions of the station.

Detailed pin allocation for digital and analog terminals, including wire colors.

Procedures for safe transport, handling, and securing the system crate.

Instructions for unpacking the station and inspecting for damage.

Steps to check delivered items against the order and report discrepancies.

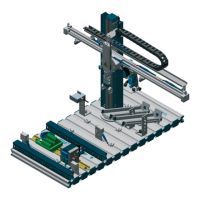

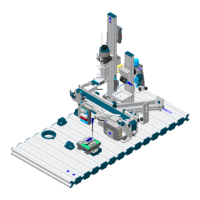

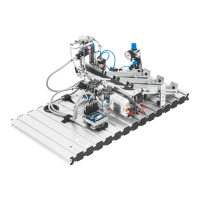

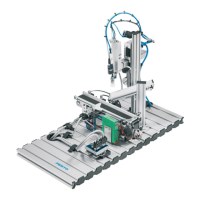

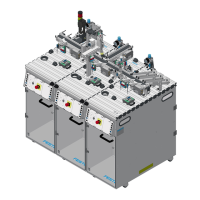

Overview of the components that constitute the MPS PA Mixing Learning System.

Description of the Mixing Station's functionality, control, and process flow.

Lists main and minor components included in the station's delivery scope.

Explanation of the flow system's operation, measurement, and control mechanisms.

Description of pumps, level monitoring methods, and sensor details.

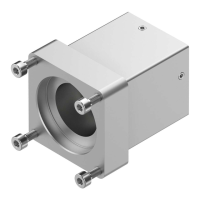

Explanation of pneumatic ball valves and the compressed air supply unit.

Overview of electrical connection board, mounting frames, and 19" frame components.

Details on PLC EduTrainer, control console, EasyPort, and USB device server.

Description of the trolley for mobile deployment of the MPS PA station.

How the Mixing Station operates as a standalone unit for mixing processes.

Integration and operation of the Mixing Station with other system stations.

Detailed steps for the mixing process, including start-up prerequisites and initial position.

Procedures for automatic operation (with/without downstream) and manual control.

Prerequisites and initial checks required for commissioning the MPS PA station.

Procedures for filling, emptying, and connecting power and air supplies.

Steps for actuating the station, cable connections, communication, and loading projects.

Guidelines for cleaning and maintaining the system components for optimal performance.

Troubleshooting common errors in piping, tanks, and the pneumatic system.

Identifying and resolving issues related to electrical systems and mechanical components.

Troubleshooting errors caused by incorrect parameter settings or connection issues.

Information on where to find additional technical documentation and updates online.

Instructions for disposing of electronic waste responsibly at designated collection points.

| Manufacturer | Festo |

|---|---|

| Type | MPS PA |

| Communication | Ethernet, Profibus, Profinet |

| Sensors | Proximity, Pressure |

| Actuators | Pneumatic |

| Application | Process Automation, Training |

| Power Supply | 24 V DC |

| Material | Aluminum |

| Weight | Varies by configuration |

| Dimensions | Varies by configuration |

| Control System | PLC-based |