Do you have a question about the Festo MPS and is the answer not in the manual?

Details the subjects covered in training, including mechanics, pneumatics, electrical systems, PLC, and fault finding.

Essential guidelines for safe and trouble-free operation of the MPS® system, emphasizing safety recommendations.

Highlights potential risks of physical injury or damage when using the MPS® system, emphasizing intended use and safe conditions.

Specifies the system's purpose for vocational and further training in automation, including advice and maintenance.

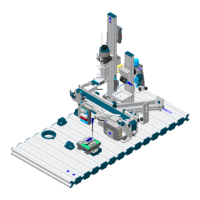

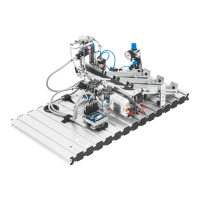

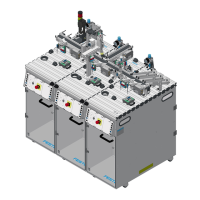

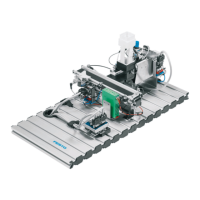

Illustrates possible combinations of MPS® stations as downstream units in a production flow.

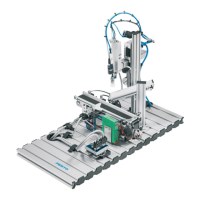

Introduces the Handling station, defining its role in material flow and its primary functions.

Describes the station's function in determining workpiece characteristics, fetching, and depositing them on slides.

Details the operational sequence, including starting prerequisites, initial positions, and workpiece handling steps.

Explains the Receptacle module where workpieces are manually inserted and detected by a diffuse sensor.

Describes the PicAlfa-pneumatic module, its handling components, pneumatic drives, and flexible capabilities.

Details the PicAlfa-electrical module, its electrical linear axis, and how slide positions are sensed electrically.

Explains the Slide module's purpose for transporting and storing workpieces and its adjustable angle of inclination.

Lists the necessary components and prerequisites for commissioning the MPS® station.

Provides instructions for the mechanical assembly of the profile plate and control console for the station.

Details the procedure for setting the mechanical end stops for the linear axis positions.

Guides on adjusting diffuse and proximity sensors for proper station function.

Details pneumatic connection procedures and voltage supply requirements for the station.

Guides on loading PLC programs for different controllers (Siemens, Festo, Allen Bradley, Mitsubishi).

Describes how to initiate and operate the station's sequence, including stopping and cycle selection.

| Category | Modular Production System |

|---|---|

| Manufacturer | Festo |

| Power Supply | 24V DC |

| Compressed Air Supply | 6 bar |

| Components | Various modules including handling, testing, and processing stations |

| Control | PLC (Programmable Logic Controller) |

| Programming | Ladder Diagram, Function Block Diagram, Structured Text |

| Communication | PROFIBUS, PROFINET, Ethernet |

| Actuators | Pneumatic cylinders, electric drives |

| Sensors | Proximity sensors, photoelectric sensors, pressure sensors |

| Material | plastic components |