6. Commissioning

© Festo Didactic 655633 93

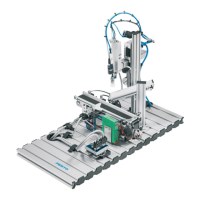

One-way flow control valves are used to regulate exhaust air flow rates with double-

acting cylinders. In the reverse direction, air flows through the non-return valve with

full cross-sectional flow.

Uncontrolled supply air and controlled exhaust hold the piston between air cushions

(improves motion, even with load changes).

Prerequisite

– Cylinder is tubed up

– Compressed air supply switched on.

Execution

1. Screw in the restrictors of the one-way flow control valves at first completely and

then loosen again one turn.

2. Start a test run.

3. Slowly open the one-way flow control valves until the desired piston speed is

reached.

Documents

• Data sheets

One-way flow control valve (175056) in the directory English\4_Handling\Data

sheets on the CD-ROM supplied.

• Operating instructions

Pneumatic cylinders (391172) in the directory English\4_Handling\Operating

instructions on the CD-ROM supplied.

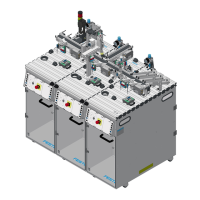

A visual check must be carried out before each commissioning!

Prior to starting up the station, you will need to check:

• The electrical connections

• The correct installation and condition of the compressed air connections

• The mechanical components for visual defects

(tears, loose connections etc.)

Eliminate any damage detected prior to starting up the station!

6.5

Adjusting one-way flow

control valves

6.6

Visual check

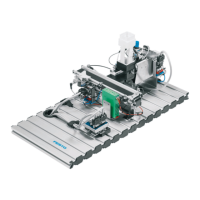

Loading...

Loading...