Go to fetco.com for the latest versions of all information Page 9 P167 March 2018

Saving changes and exiting PROGRAMMING

The brewer will save changes only from the “F” menu. DO NOT reboot brewer or toggle ON/OFF-exit as below.

DO NOT attempt to save by rebooting (turning power OFF then ON). All changes made will be discarded and brewer will remain in the existing default settings

TO EXIT PROGRAMMING & HOW TO SAVE CONTROL SETTING CHANGES

HOW TO SAVE CHANGES AND EXIT-The brewer is in PROGAMMING mode.

You may exit programming at any time. After programmed settings are saved, the brewer exits PROGRAMMING

mode and returns to regular brew operations. Settings are saved only when brewer returns to OPERATING MODE

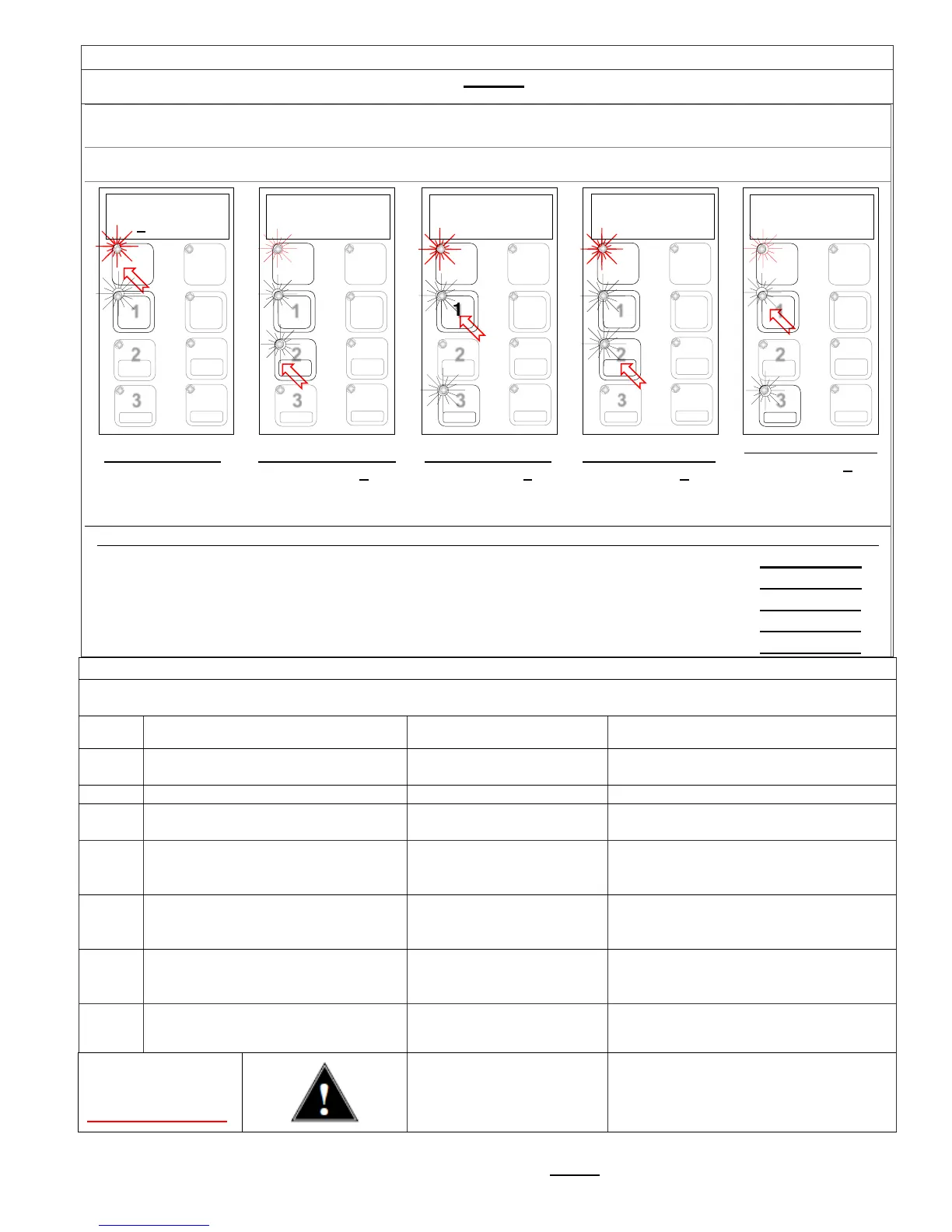

From any screen-

Press STOP button

until the EXIT (“F”)

screen appears

From the “F” screen

Press button 2 to

toggle to the EXIT-

YES screen

From EXIT screen

Press button 1 to

toggle to the SAVE

screen

From SAVE screen

Press button 2, to

toggle to the SAVE-

YES screen

Press button 1 to

SAVE your changes

and EXIT to

NOTE:

User Settings will be erased and overwritten to factory default settings by the following five programming changes

1) When setting or changing units of display for the tank temperature (F Fahrenheit or C Celsius). (SETTING B4)

2) When setting or changing units of display for the volume (G gallons, L liters). (SETTING B5)

3) When setting brewer model The software sets equipment to brewer defaults (SETTING E2)

4) When resetting (Reloading) DEFAULTS (SETTING E5)

5) When loading from USB (Reloads to defaults ) (SETTING E7)

DO NOT CLEAR ERROR CODES UNTIL ERROR IS IDENTIFIED AND/OR CORRECTED

Contact specialized personnel for error codes

Code Description Possible Cause Corrective Action

001

Software error-error on start up or

corrupted software

Improper start-up or

shutdown

Restart , if still fault: reload software

Short-circuit in temperature probe

051 Open temperature probe.

Bad probe connection, or

probe failure.

Check all connections. Replace probe

if necessary.

100

Initial fill time took longer than

Water supply flow rate is

too low.

Watch for short potting during brew

cycle. Investigate cause of low flow

rate. (Clogged water filter...)

101

Tank did not refill within expected

Water supply flow rate is

too low.

Watch for short potting during brew

cycle. Investigate cause of low flow

rate. (Clogged water filter…)

201

Heater open, high limit thermostat,

or Solid State Relay (SSR) fault

Failure of: heating element,

SSR, high Limit or low

Check and replace heating elements if

necessary.

255 Touch pad error

Usually from longer than 2

min contact. Or faulty

Restart , if still fault: reload software.

If mechanical: reassemble correctly

NO

BSKT

Insert Brew Basket

place

This is a

Insert brew basket into brewer rails to

enable brewer

- F

NO +

Loading...

Loading...