22/68

GB

5 USING THE COMPRESSOR

CHECKING THE SETTINGS

1) When the machine is ready, “PRESS START TO START” appears on the display. You can check the

overall setting of the control unit by pressing the “UP arrow” or DOWN arrow” keys of the push button control

panel:

Note! Refer to the menu descriptions to better comprehend the meaning of the parameters listed

hereafter.

Press the DEFAULT key to exit.

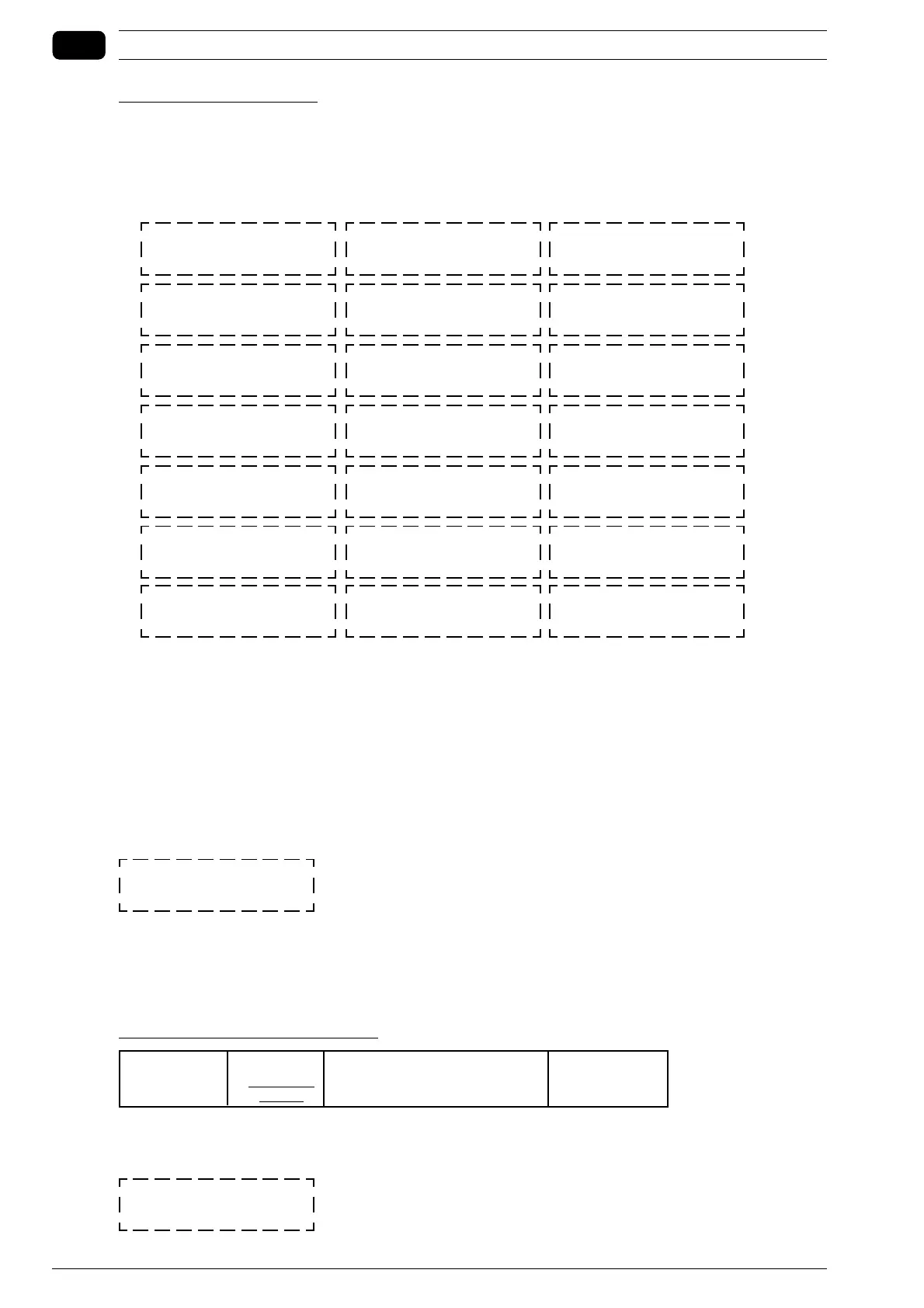

2) Press the “left arrow” and the “right arrow” key on the push button control panel to view the following on

the display for a few seconds:

- Total hours of operation (OL)

- Hours of operation under load (OC)

- Number of hours left to maintenance (MANUT)

Example:

Where:

OL = 150 h

OC = 100 h

MANUT = 2850 h

MENUS THE CLIENT CAN ACCESS

PASSWORD MENU HOW TO ACCESS HOW TO EXIT

“< + DEFAULT” AUTOTEST

Keys < and DEFAULT pressed together

“STOP” key

“> + DEFAULT” CLIENT

Keys > and DEFAULT pressed together

“DEFAULT” key

AUTOTEST (“< + DEFAULT” simultaneously)

To access the menu, press the < and DEFAULT keys simultaneously.

The AUTOTEST function automatically checks the electrical connections of the machine.

TESTING

STOP TO EXIT

TH: 150 - - MAINTEIN

LH: 100 - - 2850

To exit the AUTOTEST function, press the Stop button as indicated on the display.

SELECT PSI/BAR 2/1

(---)

IDLE RUN TIME

(---)

No. OIL LOW TEMP AL.

(---)

SELECT FAR/CELS 2/1

(---)

MAX P. CUSTOMER

SETUP (---)

HOURS WORKED

(---)

PRESS.SENSOR SETUP

(---)

STAR-DELTA TIME

(---)

No. MOTOR

THERM.ALARMS (---)

LANGUAGE CHOICE (0-4)

(---)

BUZZ. (y/n) (1/2)

(---)

No.MOTOR TEMP.

ALARMS (---)

REN.CONTR. (2/1) (y/n)

(---)

MIN P. CUSTOMER

SETUP (---)

HOURS OF

COMPRESSION (---)

MAINTENTENANCE TIME

(---)

NET SWITCH OFF HOUR

(---)

ALARM OIL TEMPERAT

(---)

ALARM PRESSURE

(---)

No.OIL TEMP. ALARMS

(---)

No.PRESSURE ALARMS

(---)

Loading...

Loading...