24/68

GB

5 USING THE COMPRESSOR

1

To summarise:

CALIBRATION LIMITS

- Max. P. < Alarm P. - 0.5 bar/7.2 psi

- Min. P. > 5.5 bar/79.8 psi

- DP = (Max. P. – Min. P.) > 1 bar/14.5 psi

- 120 s < IDLE RUNNING TIME < 600 sec

- “0” to reset the meter.

The “Alarm P.” can be modified from the manufacturer’s “SETTING” menu.

ALARMS

The alarms that may trigger can be grouped in two categories:

A) Stopped ALARM (red steady LED)

B) Warning ALARM (red flashing LED)

C) INVERTER stopped and warning ALARMS (Red steady or flashing LED)

A) Stopped ALARM

This type of alarm stops the compressor and is pointed out by the red steady LED (ALARM on

dashboard), by a beeping buzzer and by a flashing message on the display indicating the cause for the

actual alarm.

1. When the Pressure exceeds the limit alarm pressure (case in which the increase in pressure is so quick

that the max. cut-off pressure is unable to intervene) the following appears on the display:

ALARM

PRESSURE

THE COMPRESSOR STOPS!

To reset the machine:

Once the pressure has dropped (P < Alarm P.) press the “RESET” key to set the compressor ready to

start again. At this stage the following appears on the display:

2. When the limit oil-air temperature is exceeded (T>alarm T.=105°C/221°F) the following appears on the

display:

PRESS START

TO START

ALARM

TEMPERATURE

THE COMPRESSOR STOPS!

To reset the machine:

Once the temperature has dropped by at least 10°C/18°F compared to the limit temperature, you can

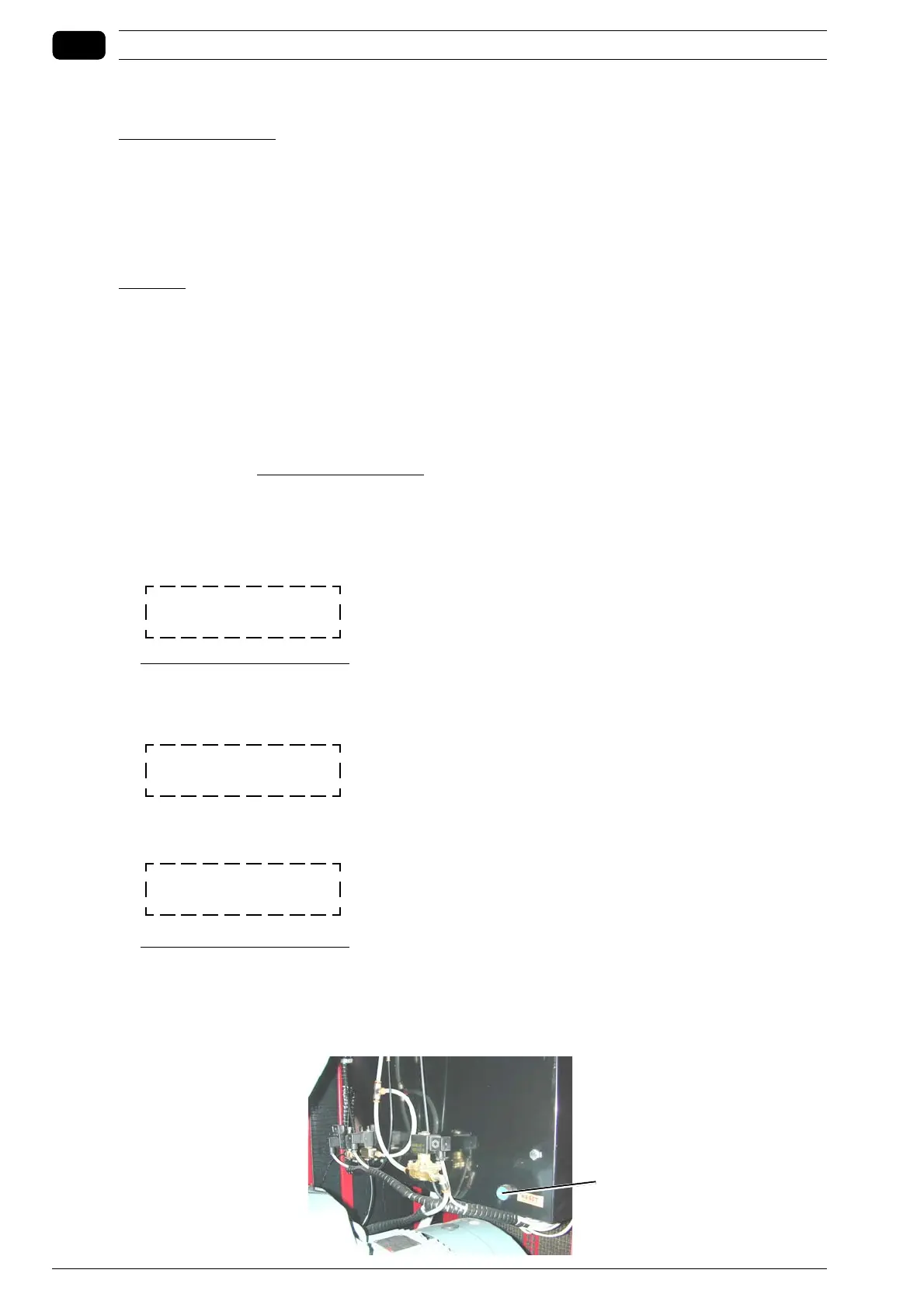

RESET the compressor internally (you need to open the front hatch and then press the board RESET

button).

Loading...

Loading...