32/50

GB

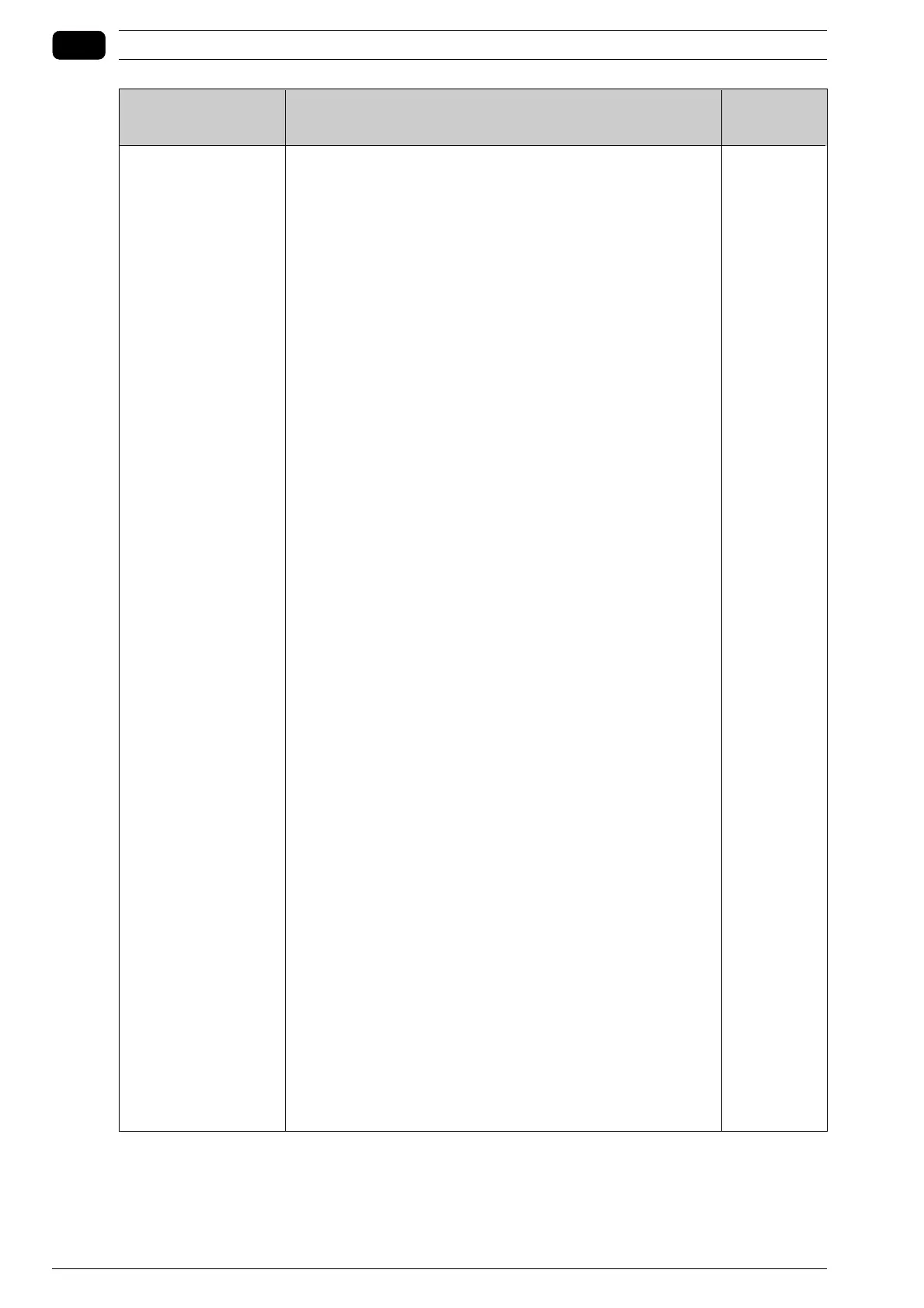

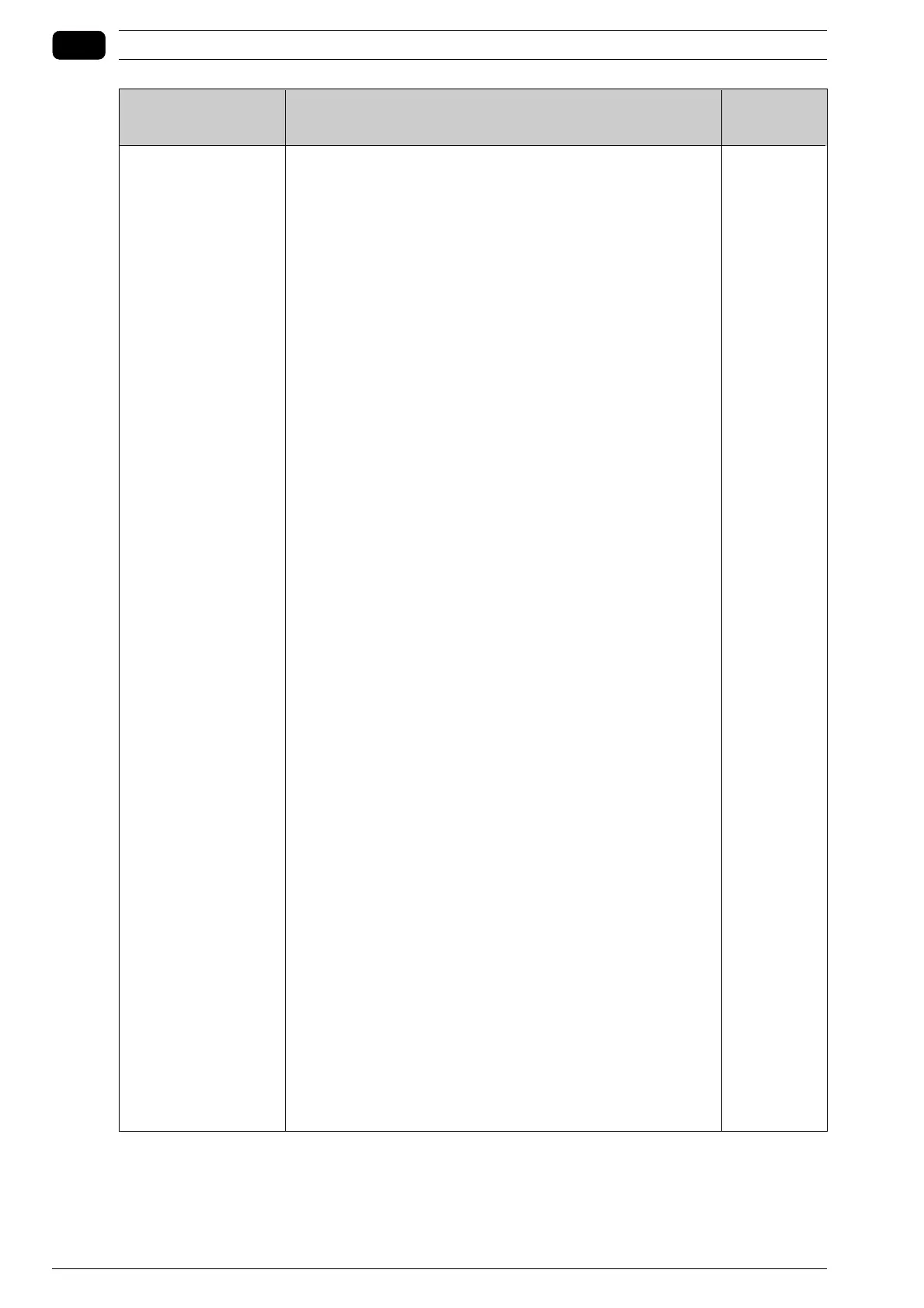

6 COMPRESSOR MAINTENANCE

Interval

(hours)

weekly

500 hours following

first start-up

every 2500 hours or

at least once a year

every 5000 hours

every 7500 hours

every 12500 hours

every 20000 hours

Jobs

to be performed

Check if the filters of the electric cabinet are clogged (for versions SD) ...

Check if the anti-dust pre-filter is clogged ..............................

Check the oil level .................................................................

Check the electrical connections and tighten if necessary .....

Replace the oil filter cartridge ................................................

Replace the filter cartridge of the oil separator ......................

Replace the air filter cartridge ................................................

Check the joint .......................................................................

Clean the air/oil radiator .........................................................

Check filters in electrical cabinet and replace if necessary ....

Grease the motor bearings ....................................................

Clean inverter dissipator (for SD versions) ............................

Check the safety valve ..........................................................

Check the electrical connections and tighten if necessary .....

Change the oil .......................................................................

Check the hydraulic seals .....................................................

Test motor trip switch (for DR versions) ................................

Test oil trip switch ..................................................................

Overhaul the suction valve ....................................................

Check the hoses and replace if necessary............................

Overhaul oil separator flange ................................................

Grease the minimum pressure valve.....................................

Replace Fluorflon pipes 6x4 and 10x10 ................................

Replace the screw oil seal ....................................................

Replace the bearings of the radiator fan motor (to be done by

Technical Service centre) ......................................................

Replace the delivery OR flange .............................................

Replace inverter fan (for SD versions) ..................................

Replace the bearings of the motor (to be done by Technical Service centre) .........

Replace the bearings of the screw (to be done by Technical Service centre) .........

See

section

6.1.9

6.1.7

6.1.1

6.1.2

6.1.3

6.1.4

6.1.5

6.1.6

6.1.9

6.1.8

6.1.11

6.1.1

6.1.10

6.1.8

The above described maintenance schedule has been planned bearing in mind all the installation

parameters and recommended use of the Manufacturer.

The Manufacturer advises the customer to keep a record of all maintenance jobs performed on the

compressor, see Section 7 – Drawings and diagrams.

Loading...

Loading...