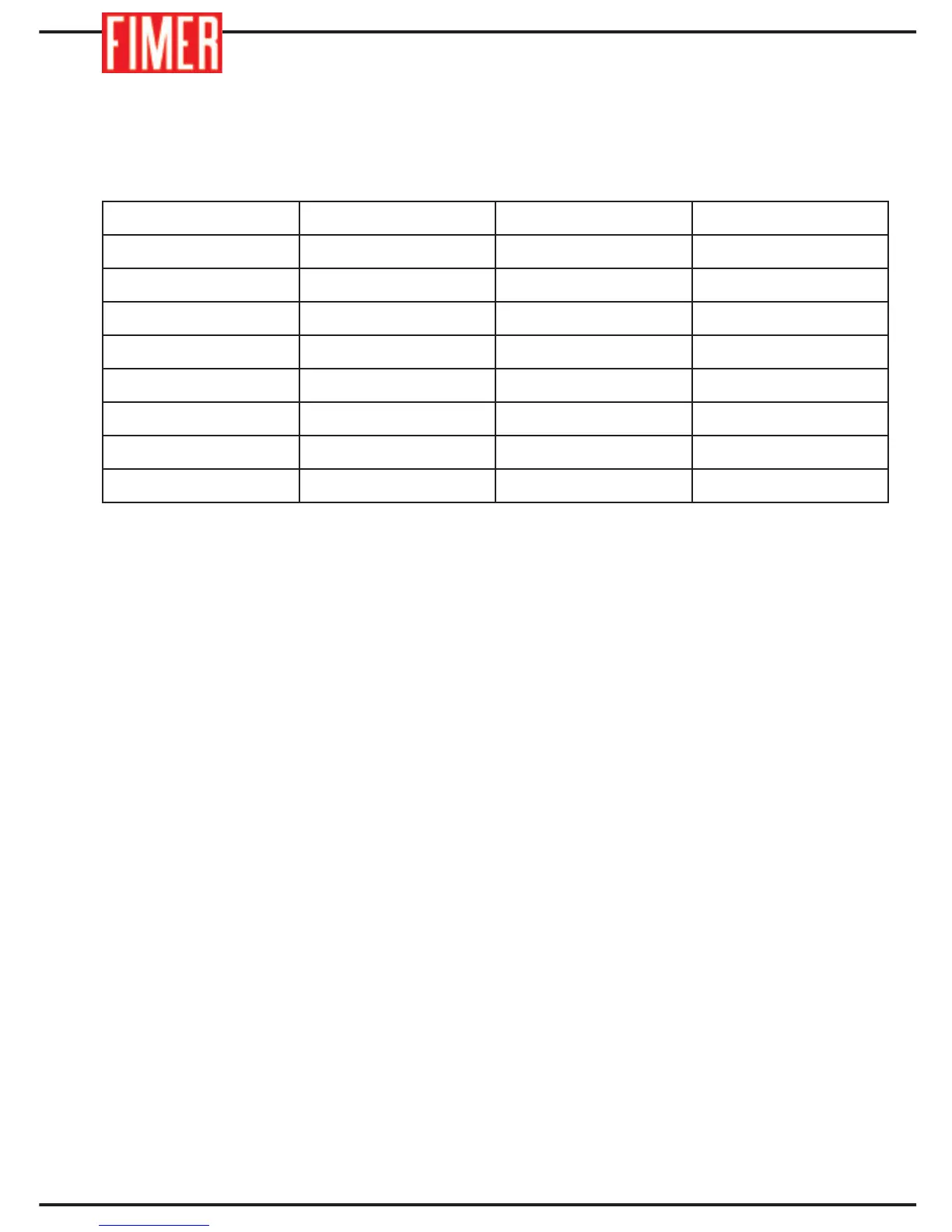

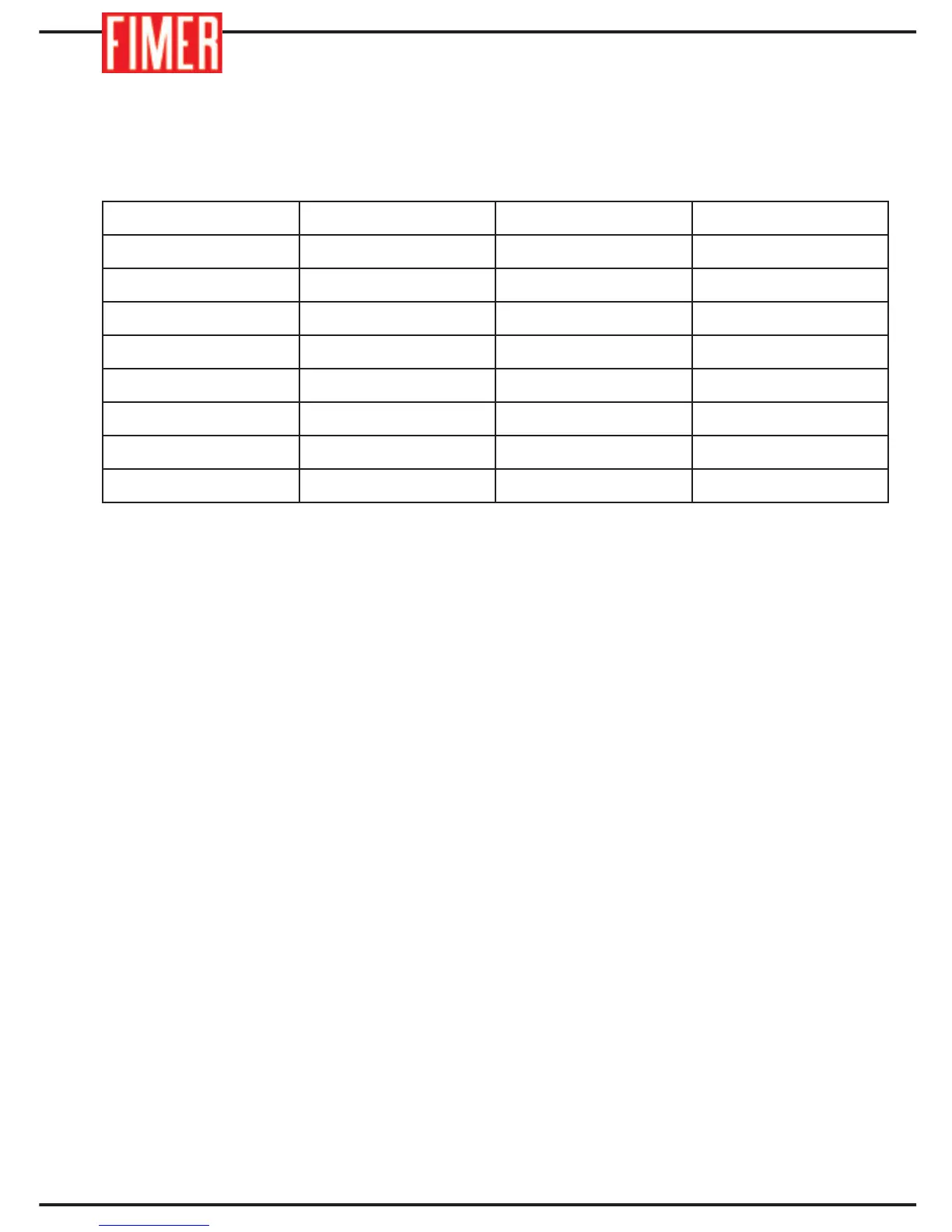

10. WELDING PROCESS

The TM230 and 260 welding machines have 11 regulating positions (13 of Fig. 1), the TM300, 350,

320W and 360W machines have 20 regulating positions (13 and 14 of Fig. 1) and the TM420W, 500W

and 650W welding machines have 30 regulating positions (13 and 14 of Fig. 1). The choice of the best

current is determined by the thickness of the material to weld. Refer to the following table for setting

the correct welding current.

11. HOW TO OBTAIN THE BEST

WELDING RESULTS

1. During welding, keep the torch at a 45° angle

from the workpiece. Keep the gas nozzle (Fig.

3A) at around 6 mm from the workpiece.

2. Continuously move the torch.

3. Do not weld in the presence of strong wind.

Strong wind could carry away the gas from the

weld pool and lead to porous welding.

4. Keep the wire clean: never use rusty wires.

5. Do not fold or twist the torch cable.

6. When changing the wire spool, clean the wire-

guide tube with compressed air.

7. Periodically remove any dust from the air

inlets using low-pressure compressed air.

Always direct the jet of air from the inside

of the machine towards the outside in order

to prevent dirt from being pushed inside the

welding machine.

12. REGULATING THE WELDING

MACHINE

Once the welding current has been set

according to the instructions in paragraph

9, keep the length of the electrical arc

between 5 and 10 mm and adjust the wire

speed to obtain the best welding result.

Carry out some test welds on a metallic

sheet that has been cleaned of any coating,

rust or paint.

NOTE: When the torch button is pressed, the fol-

lowing three functions are performed:

- gas flow;

- wire feed;

- welding current.

Start welding at a high wire speed and then grad-

ually reduce the speed via the potentiometer (9

of Fig. 1).

Continue to reduce the wire speed and listen to

the sound produced. The sound will go from a

crackling noise to a strong and regular buzzing

noise (similar to the sound of oil being fried).

This buzzing sound indicates that the correct

wire speed has been reached for the work-

piece. Each time the current is adjusted, reset

the wire speed.

Always start from the highest wire speed. This

operation prevents damaging the tip of the torch

during welding.

SPESSORE DEL PEZZO DIAMETRO FILO CORRENTE DI SALDATURA ARCO

mm mm A

0.8 - 1.0 0.6 - 0.8 60 - 100

Short - Arc

1.5 - 2.0 0.8 - 1.0 80 - 120

Short - Arc

2.0 - 3.0 1.0 - 1.2 100 - 130

Short - Arc

3.0 - 4.0 1.2 - 1.6 120 - 200

Short - Arc

> 4.0 1 150 ÷ 200

Spray - Arc

> 4.0 1.2 200 ÷ 300

Spray - Arc

> 4.0 1.6 300 ÷ 400

Spray - Arc

24

Loading...

Loading...