6

15

6.4 INSTALLATION - SEALED SYSTEM HEATING CIRCUIT

(b) Static head may be higher than calculated. In

this case it is necessary to re-measure static

head and revise expansion vessel air charge

pressure.

(C) Expansion vessel incorrect size or air charge

pressure incorrect.

Refer to BS 7074

Part 1 and BS 5449 for further information.

Nearest available stock size for additional vessel

required, at 1 bar initial system pressure (taken from

above table) is 5 Litres.

It is emphasised that the installer should be fully

acquainted with sealed system installation and

operation, calculation of total system water volume,

determining of initial system pressure required and

calculation of any additional expansion vessel volume

required. Warranty is void when the boiler is

installed in a system with insufficient expansions.

NB. Ensue that all expansion vessels in the same

system are set at EQUAL air charge pressures.

SYSTEM FILLING, TESTING AND MAKE-UP

Introduction

Mains cold water is supplied through the boiler

drain/fill valve.

Heating Circuit

This is the radiator heating system including the boiler

which is filled from the mains supply via a flex filling

loop to a pressure determined from the system static

head, expansion vessel size and system water volume.

This flexible filling loop should be disconnected when

boiler and system are filled and checked (see method

B).

System filling should take place slowly and can

be completed via the following method:

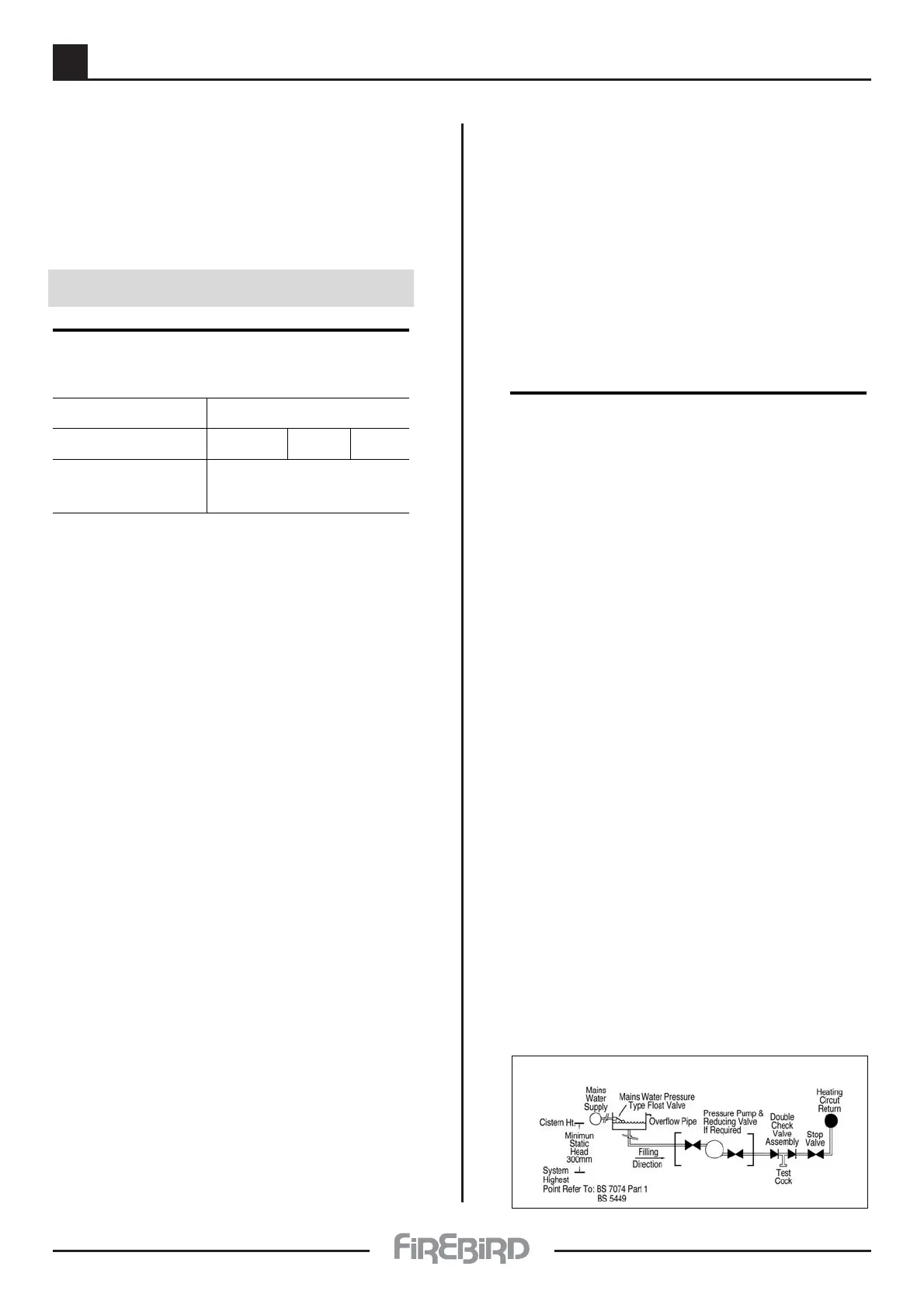

Automatic Filling

Automatic System filling may be made with a feed and

make-up cistern connected through a double check

valve and stop valve assembly to the return side of the

heating system as close to the boiler as is practical.This

cistern should be located above the heating systems

highest point to give a minimum static head of 300 mm

between it (highest point) and cistern. The manual

filling system fitted to boiler should then be

disconnected and connection points blanked off.

This system has the advantage of automatic water

make-up in the event of system pressure loss due to air

elimination and minor leaks. In any case control panel

pressure gauge should be occasionally checked.

Safety Valve Setting 3 bar

Initial System Pressure 0.5 bar 1.0 bar 1.5 bar

Total Water Content TOTAL VESSEL

of System VOLUME **

Litres Litres Litres Litres

25 2.1 2.7 3.9

50 4.2 5.4 7.8

75 6.3 8.2 11.7

100 8.3 10.9 15.6

125 10.4 13.6 19.5

150 12.5 ->[16.3]<- 23.4

175 14.7 19.1 27.2

200 16.7 21.8 31.2

225 18.7 24.5 35.1

250 20.8 27.2 39.0

FOR FURTHER INFORMATION CONSULT

APPROPRIATE TRAINING MANUALS

AND BS 7074 PART 1, BS 5449, ETC

* * When calculating size of any additional

expansion vessel required, remember to deduct

the boiler expansion vessel volume of 12 litres

from the calculated total system vessel volume

required, as given in above table.

EXAMPLE: using above table

If total water content of system is - 150 litres

and initial system pressure required is - 1.0 bar

then vessel volume required is - 16.3 litres

[from above table]

The vessel supplied with boiler is - 12.0 litres

therefore an additional vessel of - 4.3 litres

is required

(minimum)

(For this system of 150 litres - total water volume)

EXPANSION VESSEL AND SYSTEM

REQUIREMENTS

METHOD B

Loading...

Loading...