4150K and 4160K Series

14

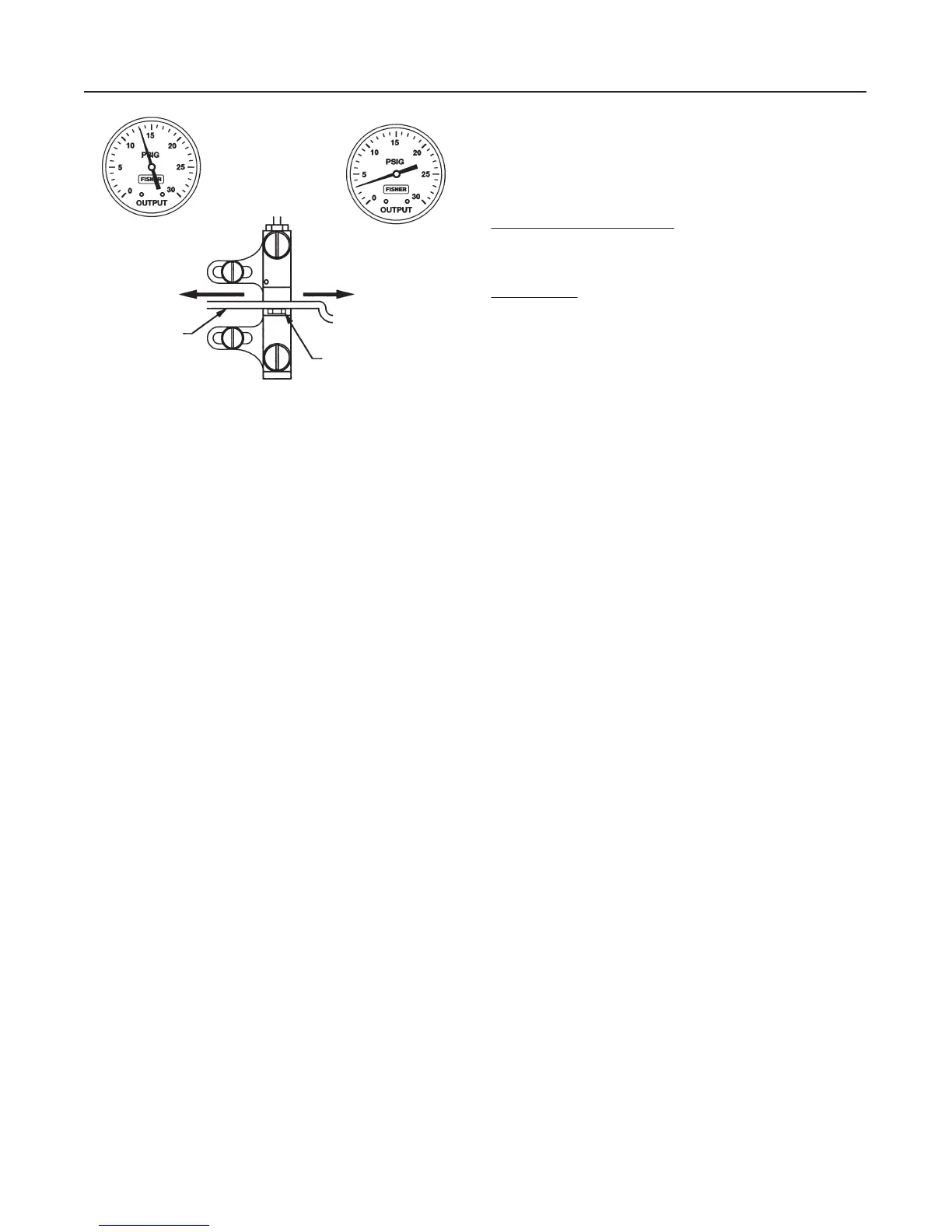

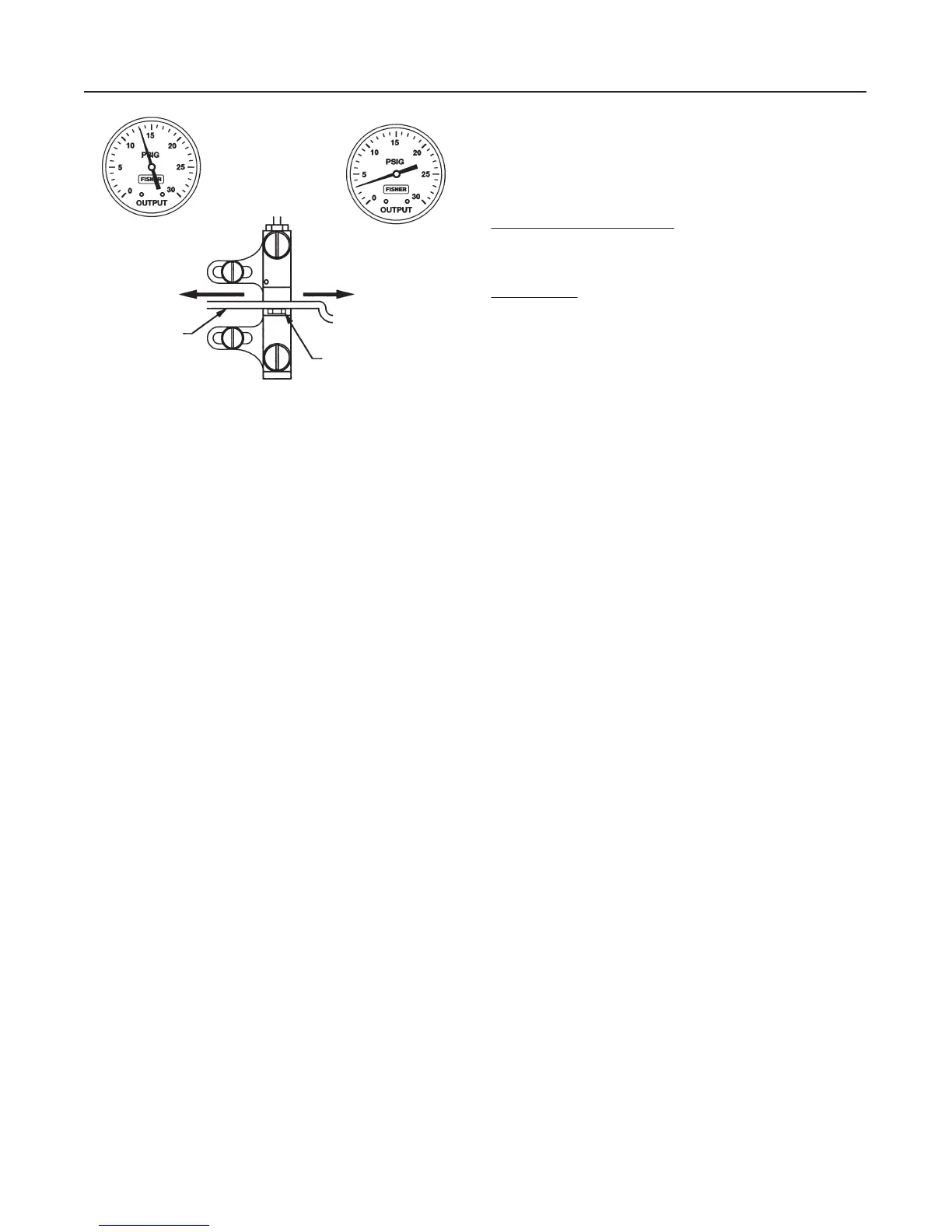

Figure 10. Reverse-Acting Controller Span Adjustment—

Proportional-Plus-Reset Controllers

IF OUTPUT IS:

ABOVE

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

BELOW

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

MOVE ADJUSTER

LEFT

MOVE ADJUSTER

RIGHT

FLAPPER

NOZZLE

NOTE:

3 TO 15 PSIG (0.1 TO 1.0 BAR) OUTPUT SHOWN.

FOR 6 TO 30 PSIG (0.2 TO 2.0 BAR) OUTPUT, ADJUST

VALUES AS APPROPRIATE.

A6155-1 / IL

Calibration: Anti-Reset Windup

Controllers with anti-reset windup have a differential

relief valve assembly (figure 20). This relief valve is

set at the factory to relieve at a 5 psi (0.3 bar) pres-

sure difference between the reset bellows pressure

and the proportional bellows pressure. The valve can

be adjusted to relieve from 2 to 7 psig (0.14 to 0.4

bar).

The relief valve can relieve on either rising controller

output pressure or falling controller output pressure. If

the arrow on the relief valve points toward the bottom

of the controller case as shown in figure 20, the valve

will relieve on falling output pressure. If the arrow

points in the opposite direction, the valve will relieve

on rising output pressure. The valve can be removed

and reinstalled with the arrow pointing in the opposite

direction to change the relief action.

Startup: Proportional-Plus-Reset

Controllers

(General Tuning Guidelines)

Calibrate the controller prior to this procedure.

1. Be sure that the supply pressure regulator is deliv-

ering the proper supply pressure to the controller.

2. Rotate the pressure-setting knob to the desired set

point.

3. Start with a reset setting of 0.05 minutes per repeat

(m/r) for fast processes, and 0.5 m/r for slow pro-

cesses.

4. Set the proportional band adjustment to 100 per-

cent for fast processes (example: liquid pressure or

liquid flow). For a slow process (example: tempera-

ture), calculate the percentage from the equation be-

low:

For a slow process, determine the initial proportional

band setting in percent from the following equation:

200 Allowable Overshoot

Pressure Span

+ P.B.

For example:

200 2 psig

30 psig

^ 13%

(1.3 proportional band setting)

5. Proportional Action:

Disturb the system by tapping the flapper lightly or

change the set point a small amount and check for

system cycling. If the system does not cycle then low-

er the proportional band (raising the gain) and disturb

the system again. Continue this procedure until the

system cycles. At that point, double the proportional

band setting and begin tuning the reset.

6. Reset Action:

Disturb the system. If the system does not cycle then

speed up the reset and disturb the system again. Con-

tinue this procedure until the system cycles. When the

system cycles multiply the reset time setting by a fac-

tor of three (3) and slow the reset down to the new

value. The reset is now tuned.

This tuning procedure may be too conservative for

some systems. The recommended proportional band

and reset setting should be checked for stability by

introducing a disturbance and monitoring the process

as previously described. For some applications, tighter

control may be desirable.

Differential Gap Controllers

This section describes the adjustments and proce-

dures for calibration and startup. The adjustment loca-

tions are shown in figure 5 unless otherwise specified.

The output of each controller is checked at the factory

before the instrument is shipped.

To convert a differential gap controller to a proportion-

al-only controller or vice versa, refer to the appropriate

procedure in the Maintenance section.

If the process pressure can be varied through all or

part of the sensing element range or through the two

desired switching points, use the process pressure for

calibration. If not, provide a pressure source to simu-

late the process pressure range for calibration proce-

dures.

To better understand the adjustments and overall op-

eration of the controller, refer to the Principle of Op-

eration section in this manual for differential gap con-

trollers and the schematic diagram in figure 14.

Loading...

Loading...