4150K and 4160K Series

8

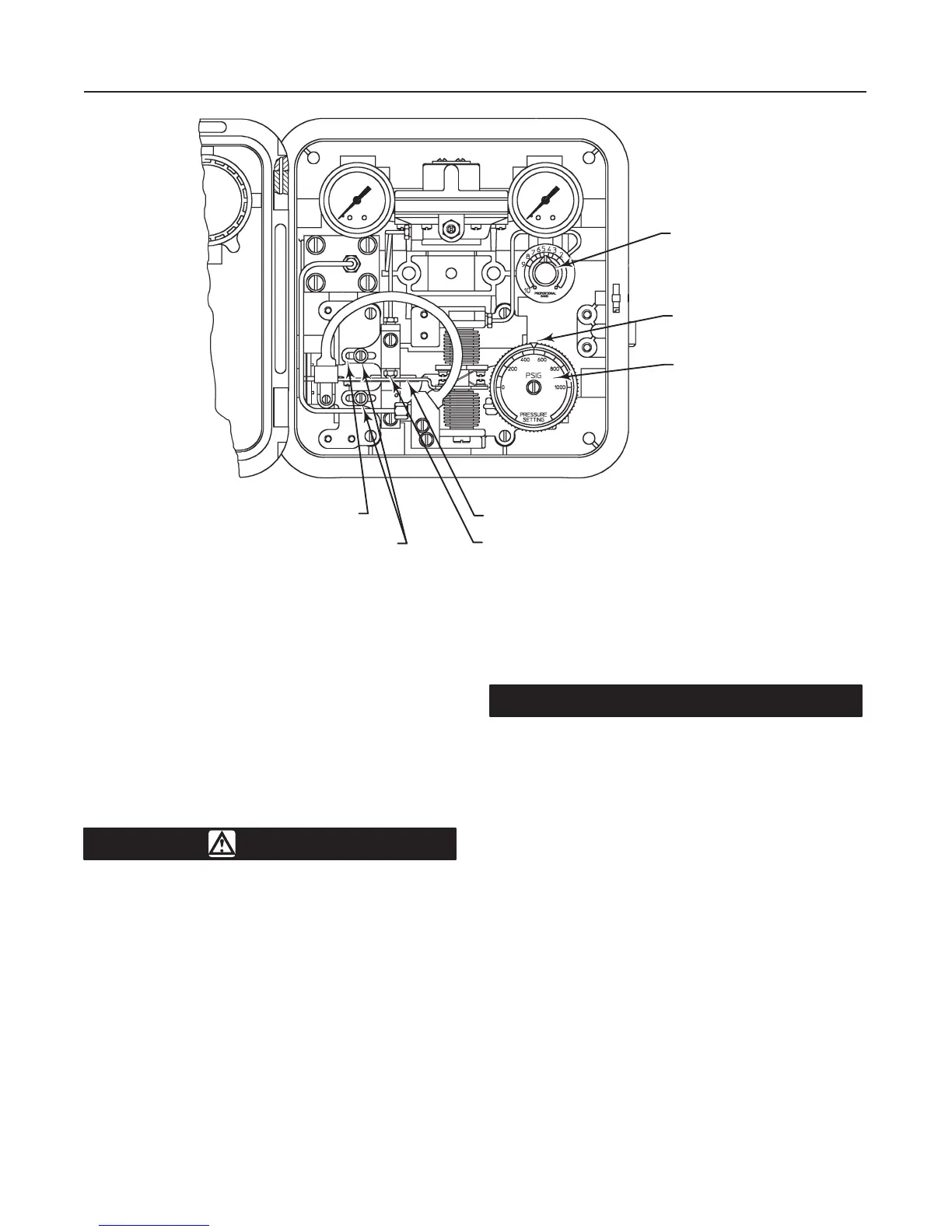

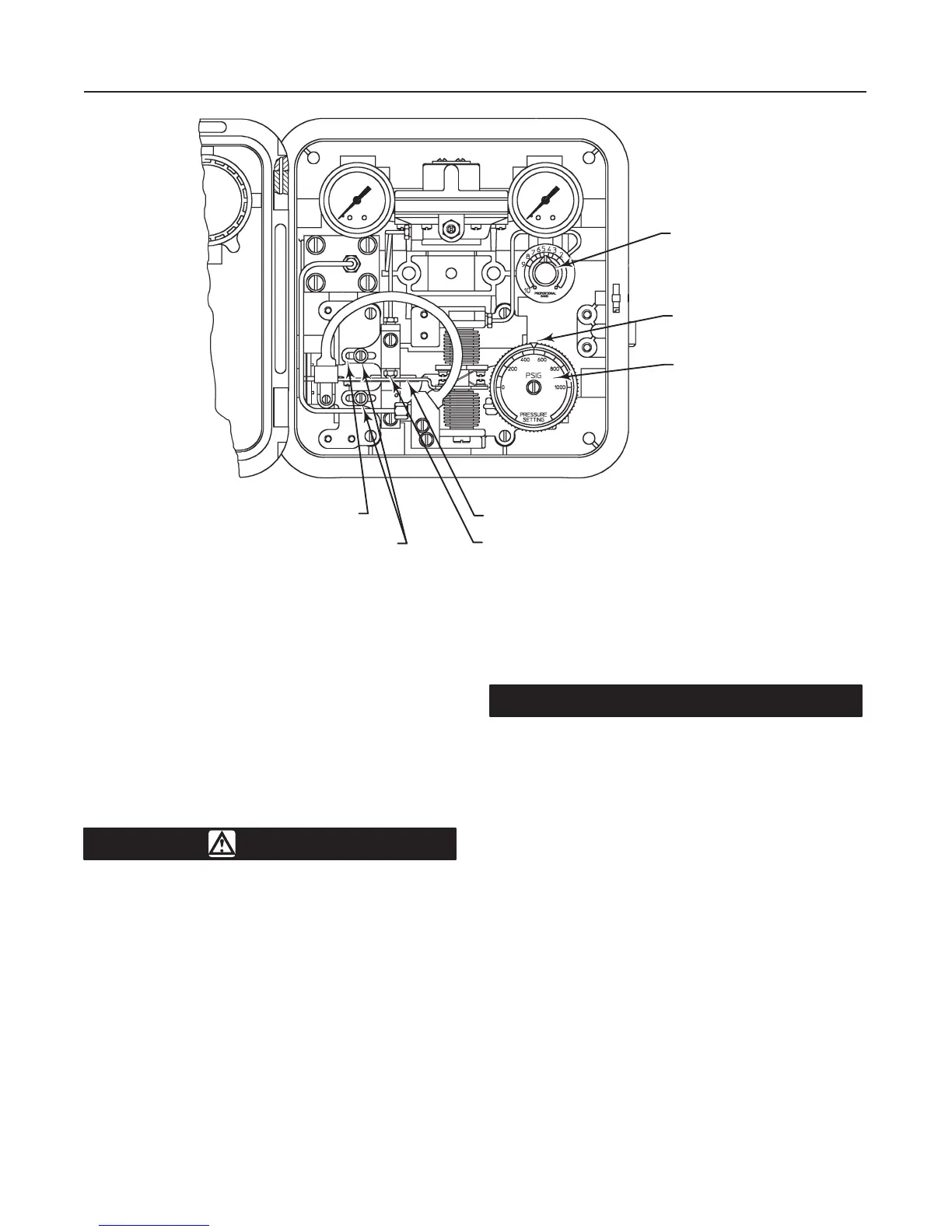

Figure 5. Proportional-Only Controller Adjustment Locations

PROPORTIONAL BAND

ADJUSTMENT KNOB

PRESSURE-SETTING KNOB

(KEY 36)

PRESSURE-SETTING

DIAL (KEY 38)

FLAPPER (KEY 45)

NOZZLE (KEY 57)

CALIBRATION ADJUSTER (KEY 41)

ADJUSTER SCREWS (KEY 43)

48B6003-A

A6038-1 / IL

cess pressure line in a straight section of pipe approxi-

mately 10 pipe diameters from the valve but away

from bends, elbows, and areas of abnormal fluid velo-

cities. For pressure-reducing service, the process line

must be connected downstream of the valve. For pres-

sure-relief service, the process pressure line must be

connected upstream of the control valve. Install a

needle valve in the process pressure line to dampen

pulsations.

Vent Assembly

WARNING

If a flammable, toxic, or reactive gas is

to be used as the supply pressure me-

dium, personal injury or property dam-

age could result from fire or explosion

of accumulated gas or from contact with

a toxic, or reactive gas. The instrument

case and cover assembly does not form

a gas-tight seal, and when the assembly

is enclosed, a remote vent line, ade-

quate ventilation, and necessary safety

measures should be used. A remote

vent pipe alone cannot be relied upon to

remove all hazardous gas. Vent line pip-

ing should comply with local and re-

gional codes and should be as short as

possible with adequate inside diameter

and few bends to reduce case pressure

buildup.

CAUTION

When installing a remote vent pipe, take

care not to overtighten the pipe in the

vent connection. Excessive torque will

damage the threads in the connection.

The vent assembly (key 15, figure 3) or the end of a

remote vent pipe must be protected against the en-

trance of all foreign matter that could plug the vent.

Use 1/2-inch (13 mm) pipe for the remote vent pipe, if

one is required. Check the vent periodically to be cer-

tain it has not become plugged.

Controller Operation

Proportional-Only Controllers

This section describes the adjustments and proce-

dures for calibration and startup. Adjustment locations

are shown in figure 5 unless otherwise specified. All

adjustments must be made with the cover open. When

Loading...

Loading...