Type 1032

3

WARNING

To avoid personal injury or property

damage caused by bursting of pressure-

retaining parts, be certain the cylinder

pressure does not exceed the pressure

limits listed in table 1. Use pressure-lim-

iting or pressure-relieving devices to

prevent the cylinder pressure from ex-

ceeding these limits.

If hoisting the valve and actuator assem-

bly or the actuator by itself, take precau-

tions to prevent personnel from being

injured in case the hoist or sling slips

unexpectedly. Refer to table 2 for actua-

tor weights. Carefully position the sling

to prevent damage to tubing or any ac-

cessories.

Actuator Mounting

Use the following steps to connect a valve and actua-

tor that have been ordered separately.

1. Place the actuator and the valve in the required

orientation.

2. Check the valve and actuator mounting surfaces,

shaft coupler and valve shaft for possible discrepan-

cies.

3. Position the shaft coupler (if furnished loose) on the

valve shaft. Then, insert the square end of the coupler

into the square hole of the actuator drive. On certain

valve/actuator/coupler combinations, it is necessary to

use a shim or adaptor (furnished) in the square end of

the coupler in the actuator drive. The actuator is usual-

ly mounted parallel with the run of pipe. However, the

actuator can be mounted in any position.

4. Tighten all bolts and nuts evenly, taking care to

center the actuator on the valve shaft.

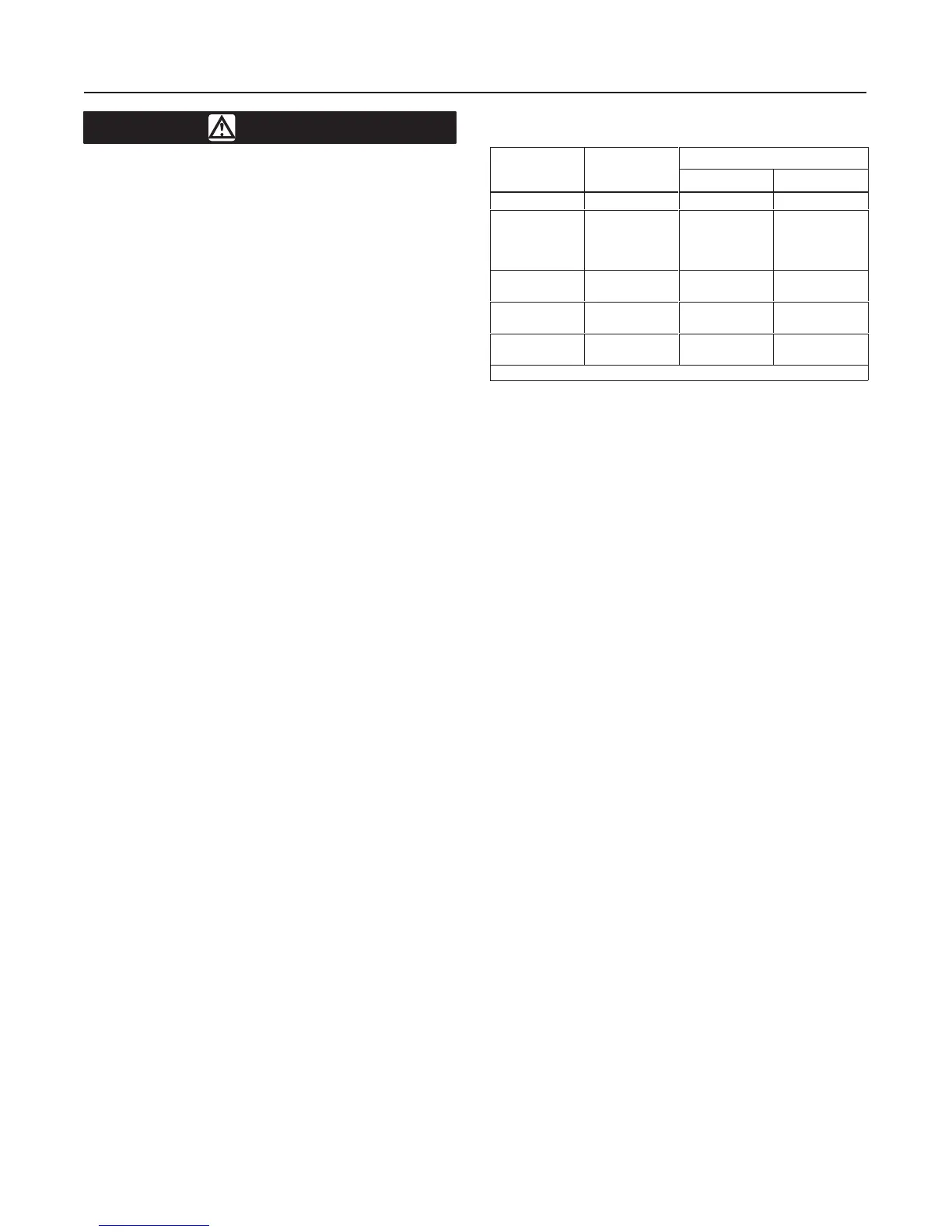

5. Refer to table 3 for valve mounting bracket to ac-

tuator bolt torques.

Table 3. V

alve Mounting Bracket

to Actuator Bolt Torque

ACTUATOR

ACTUATOR

BOLT TORQUE

MODEL

NUMBER

(1)

MOUNTING

HOLE SIZE

Lbfft Nm

45

1/4-20 UNC

4 5

70

130

185

280

5/16-18 UNC

8 11

425A

680A

3/8-16 UNC

15 20

1125

1370

1/2-13 UNC

31 42

2585

4580

3/4-10 UNC

74 100

1. Applies to both double-acting and spring-return models.

Because there are many valve and actuator combina-

tions, it is not practical to include detailed instructions

on each combination. Mountings are designed as sim-

ple as possible to keep installations easy to perform.

Travel Stop Adjustment

Type 1032 actuators are shipped from the factory with

the travel stops adjusted for approximately 90 degrees

rotation. Generally, it is necessary to make slight stop

adjustments once the actuator is installed on the

valve.

Refer to figures 10 and 11 for location of the actuator

travel stops.

Loosen the actuator travel stop lock nuts (key 10), and

adjust the travel stop adjustment bolts (key 9) to en-

sure clearance of 0.01-0.040 inch (0.3-1.0 mm) be-

tween the valve internal stops and the disk.

Loading Connection

1. Various accessories such as solenoid valves, limit

switches, and positioners may be used with these ac-

tuators. If an accessory is used, be sure that the ac-

cessory is properly connected to the actuator. If an

accessory was ordered as part of the valve and actua-

tor assembly, the pressure connection from the acces-

sory to the actuator will normally be made at the

factory.

2. Connect the supply pressure to the accessory be-

ing used or to the appropriate pressure port in the ac-

tuator. Markings are cast into the actuator adjacent to

the pressure connections as to whether supply pres-

sure forces the pistons together or apart.

3. When the valve and actuator assembly is com-

pletely installed, check for correct action (air-to-open

or air-to-close) on spring-return actuators. For suc-

cessful operation, the actuator and valve shaft must

move smoothly in response to supply pressure

changes in the pressure cylinder.

Loading...

Loading...