Type 1032

4

Startup

When the valve and actuator assembly are first put

into service, slight leakage past the piston O-rings

might be detected. This is due to the O-rings having

been held in one position tending to cause a ‘‘set’’ in

the O-ring. In such cases, operate the actuator

through several cycles, thereby energizing the O-rings

and resulting in a ‘‘re-seating’’.

The stroking speed will be determined by a number of

factors, including the distance from the pressure

source, supply line size, supply line pressure, acces-

sories, torque requirement of the valve, and size of the

actuator. Due to the interaction of these variables, it is

difficult to specify a normal stroking speed.

Principle of Operation

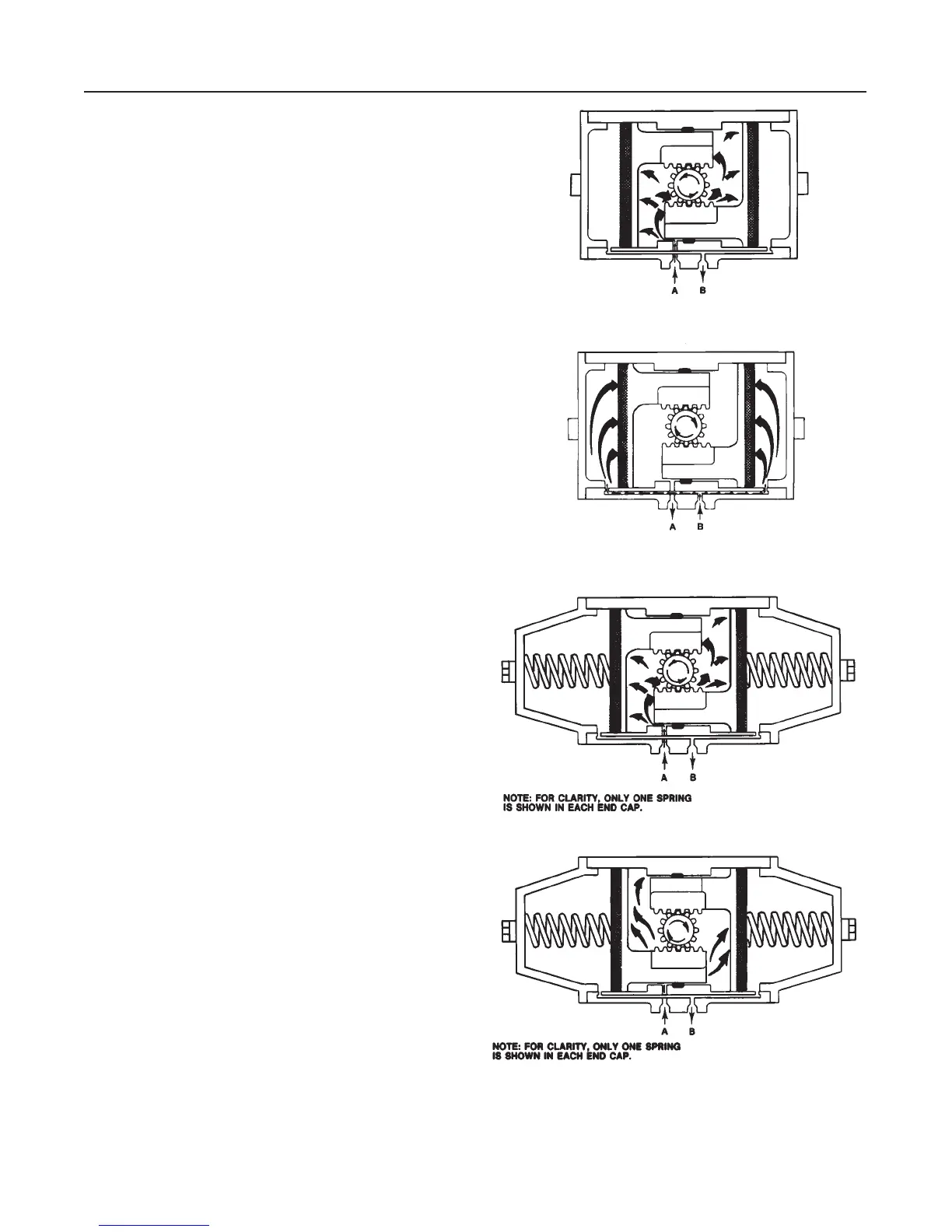

Double-Acting Actuators

For counterclockwise output rotation, refer to figure 2.

With actuator pistons installed as shown in figure 2,

supply pressure is applied to port A which forces the

pistons apart. The linear travel of the pistons is con-

verted to a counterclockwise rotation of the pinion and

valve shaft by the rack-to-pinion connection. The vol-

ume on top of each piston is exhausted through

port B.

For clockwise output rotation, refer to figure 3. With

actuator pistons installed as shown in figure 3, supply

pressure is applied to port B which forces the pistons

together. The linear travel of the pistons is converted

to a clockwise rotation of the pinion and valve shaft by

the rack-to-pinion connection. The volume between

the pistons is exhausted through port A.

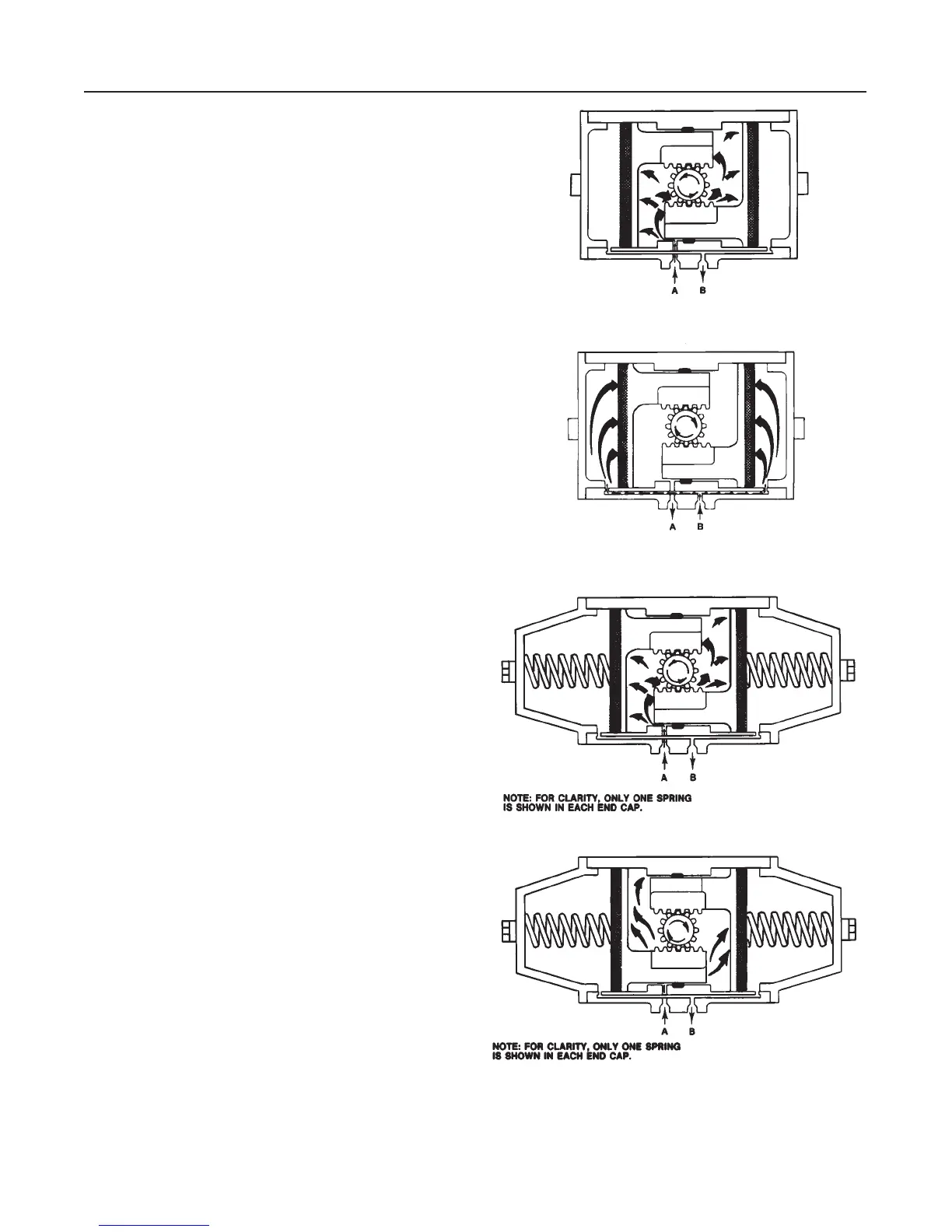

Spring-Return Actuators

For counterclockwise output rotation, refer to figure 4.

With actuator pistons installed as shown in figure 4

(fail-closed action for valves with clockwise to close

disk rotation), supply pressure is applied to port A.

This pressure forces the pistons apart, compresses

the springs, and opens the valve. The linear travel of

the pistons is converted to a counterclockwise rotation

of the pinion and valve shaft by the rack-to-pinion con-

nection. The volume on top of each piston is ex-

hausted through port B. Upon loss or removal of sup-

ply pressure, the compressed springs move the

pistons together and close the valve.

Figure 2. Double-Acting Actuator with

Counterclockwise Output Rotation

A5818 / IL

Figure 3. Double-Acting Actuator with

Clockwise Output Rotation

A5819 / IL

Figure 4. Spring-Return Actuator with

Counterclockwise Output Rotation

A5820 / IL

Figure 5. Spring-Return Actuator with

Clockwise Output Rotation

A5821 / IL

Loading...

Loading...